Acid-resistant coated pigments

A pigment, coating technology, applied in the direction of coating, fibrous filler, etc., can solve problems such as burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

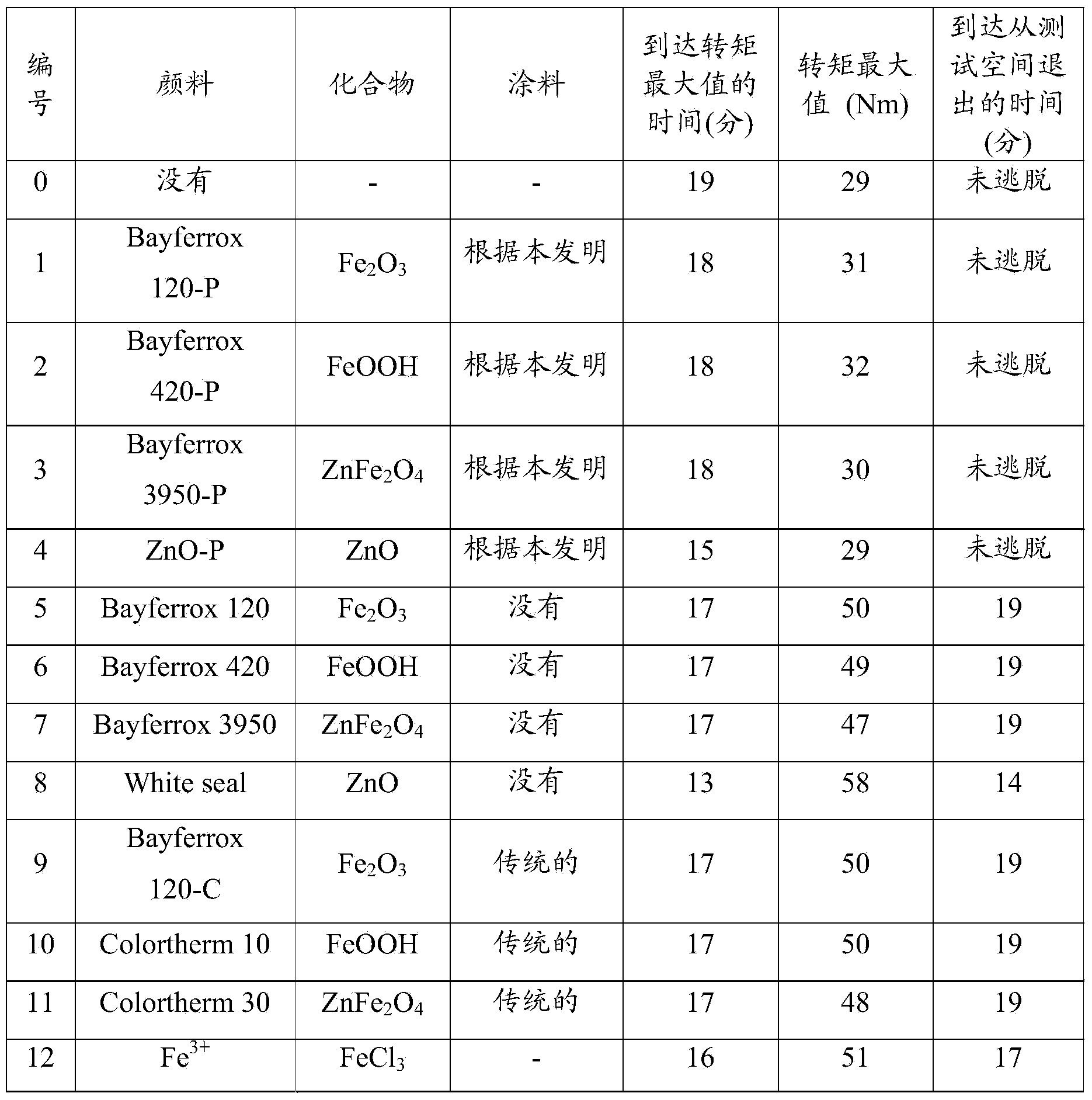

Examples

Embodiment

[0026] 1. Method for producing pigments coated by an acid-resistant method

[0027] Reaction mixture No. 1 consisting of 5 kg of Bayferrox 120 (uncoated ferric oxide) and 0.5 kg of pentaerythritol powder was introduced into a vacuum pressure intensive heating mixer (inhouse construction). The reaction mixture of No. 1 was heated to 250° C. under a pressure of 1 mbar with a centralized mixing box. After a reaction time of 15 minutes, it was ventilated and cooled. The sample taken out is No. 1 paint applied in an acid-resistant way.

[0028] Do the same for the following paints that are applied by acid-resistant means:

[0029] The reaction mixture of No. 2 composed of 2 kg of Bayferrox 420 (uncoated ferric oxyhydroxide) and 0.2 kg of pentaerythritol is used to prepare the pigment coated with acid-resistant method of No. 2;

[0030] The reaction mixture of No. 3 composed of 2 kg of Bayferrox 3950 (uncoated zinc iron spinel with zinc ferrite composition) and 0.2 kg of pentaery...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com