Circlip for cylindrical roller bearing and its production method

A technology for cylindrical roller bearings and circlips, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., and can solve the problems of loose dimensions and tolerances of circlips, difficult control of main dimensions and tolerances, winding of spring steel strips and Lock complex problems to achieve the effect of solving burn problems, simple manufacturing process and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

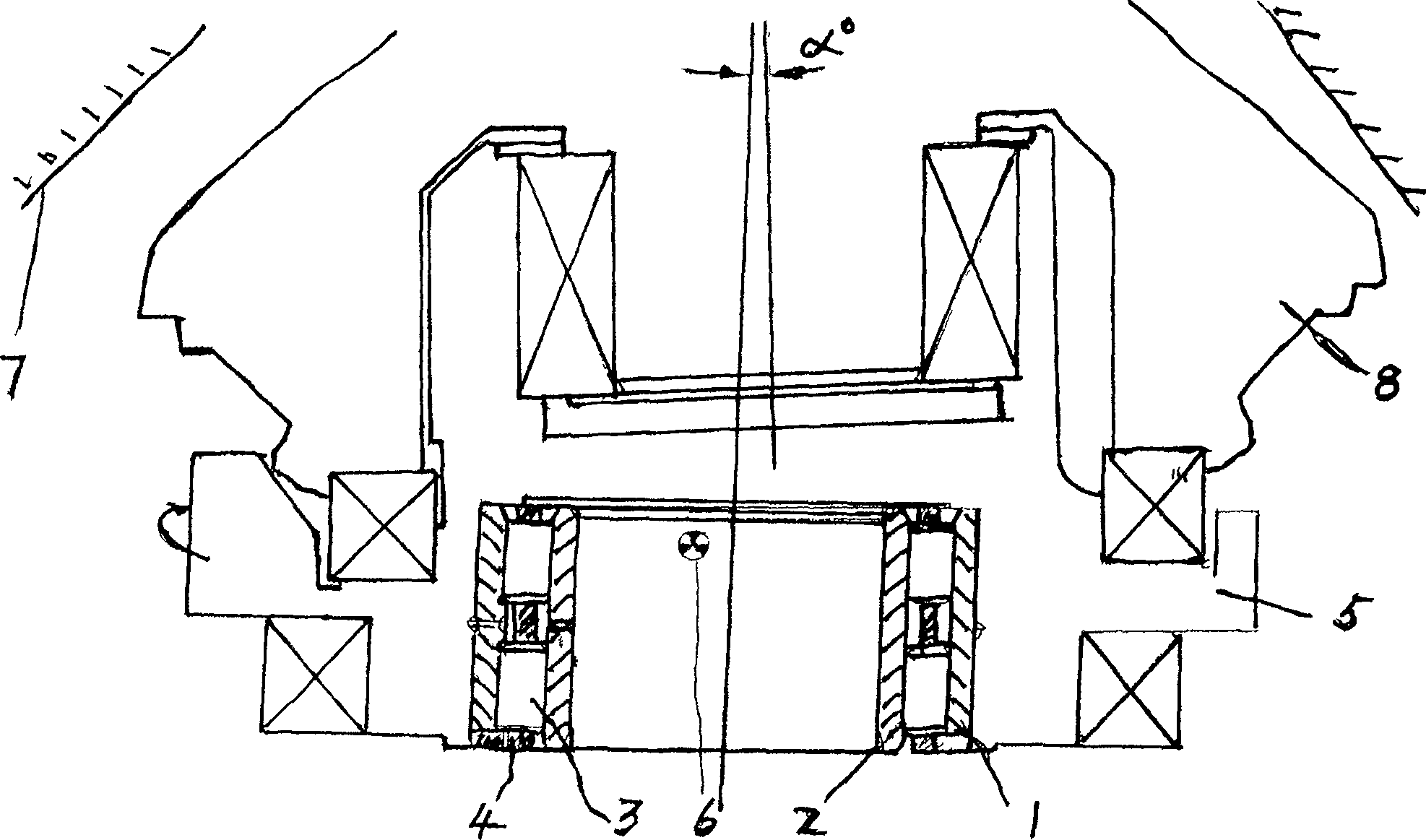

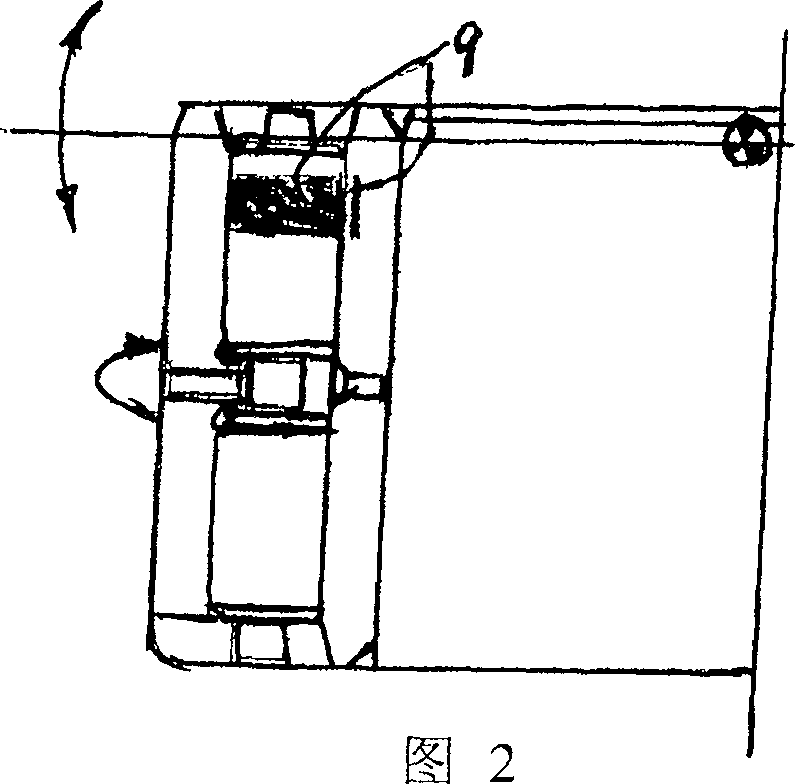

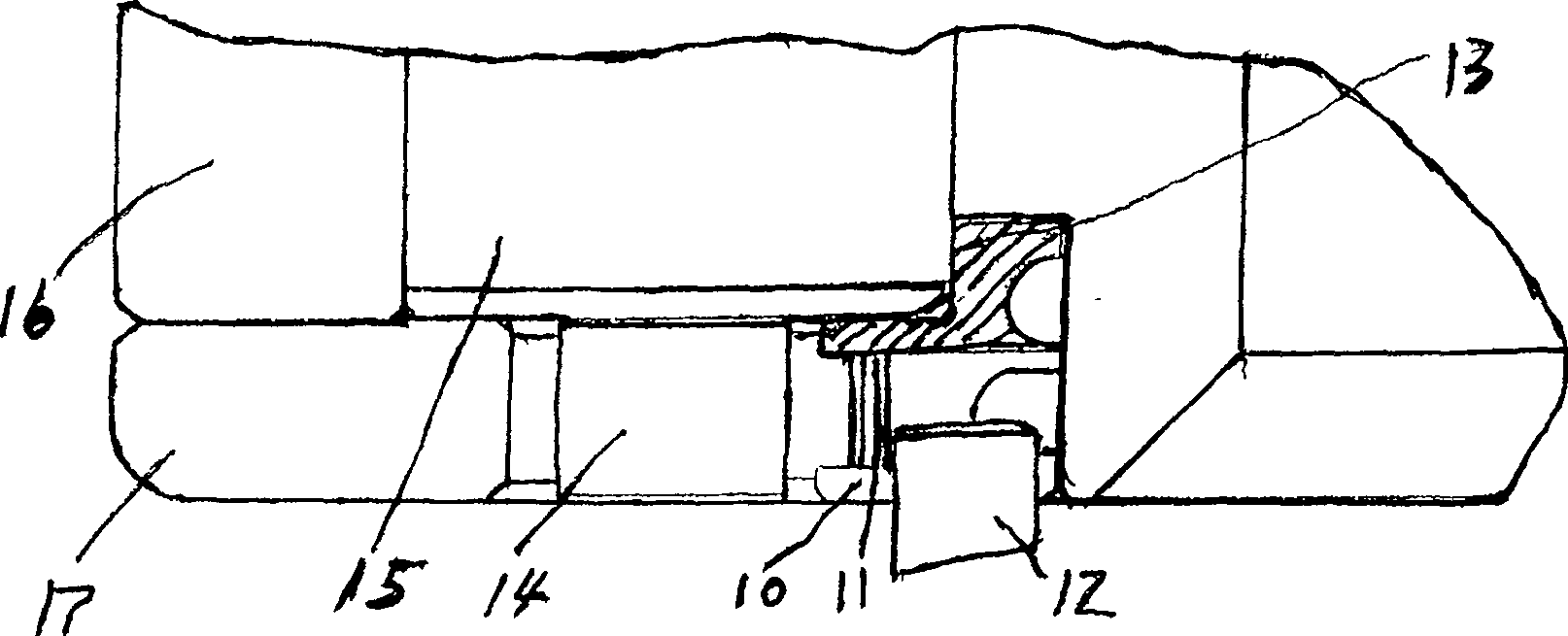

[0034] Depend on Figure 4 , Figure 5 It can be seen that the elastic circlip is connected in a way of butting two ends, and an opening 18 is provided on the lower end surface 25 of the connecting end, and an oblique cut 19 is arranged on the upper end surface of the connecting end, and the slope of the oblique incision is 45°. The inner ring of the ring is provided with two oil seal grooves 22, and the oil seal grooves 22 extend outward from the opening 18 with a depth gradually becoming shallower. The small outer diameter of the retaining ring is the raceway surface 13, and the large outer diameter is the fixed spring steel sheet 23. The fixed groove 11 of the spring steel sheet, the spring steel sheet 23 is arranged in the fixed groove 11 of the spring steel sheet with each 30 ° of circumference around the center line of the circlip opening 18. The spring steel sheet 23 of the circlip of the present invention is made up of two steel sheets of 0.5mm, and the spring steel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com