Method for producing hydrogen or deuterium, method for producing hydrogenated or deuterated organic compound, method for hydrogenating or deuterating organic compound, method for dehalogenating organic compound having halogen, and ball for use in mechanochemical reaction

一种机械化学反应、有机化合物的技术,应用在有机化合物的制备、有机化学方法、有机化学等方向,能够解决反应试剂成本高危险性、金属不可逆等问题,达到反应控制容易、接触次数增加的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

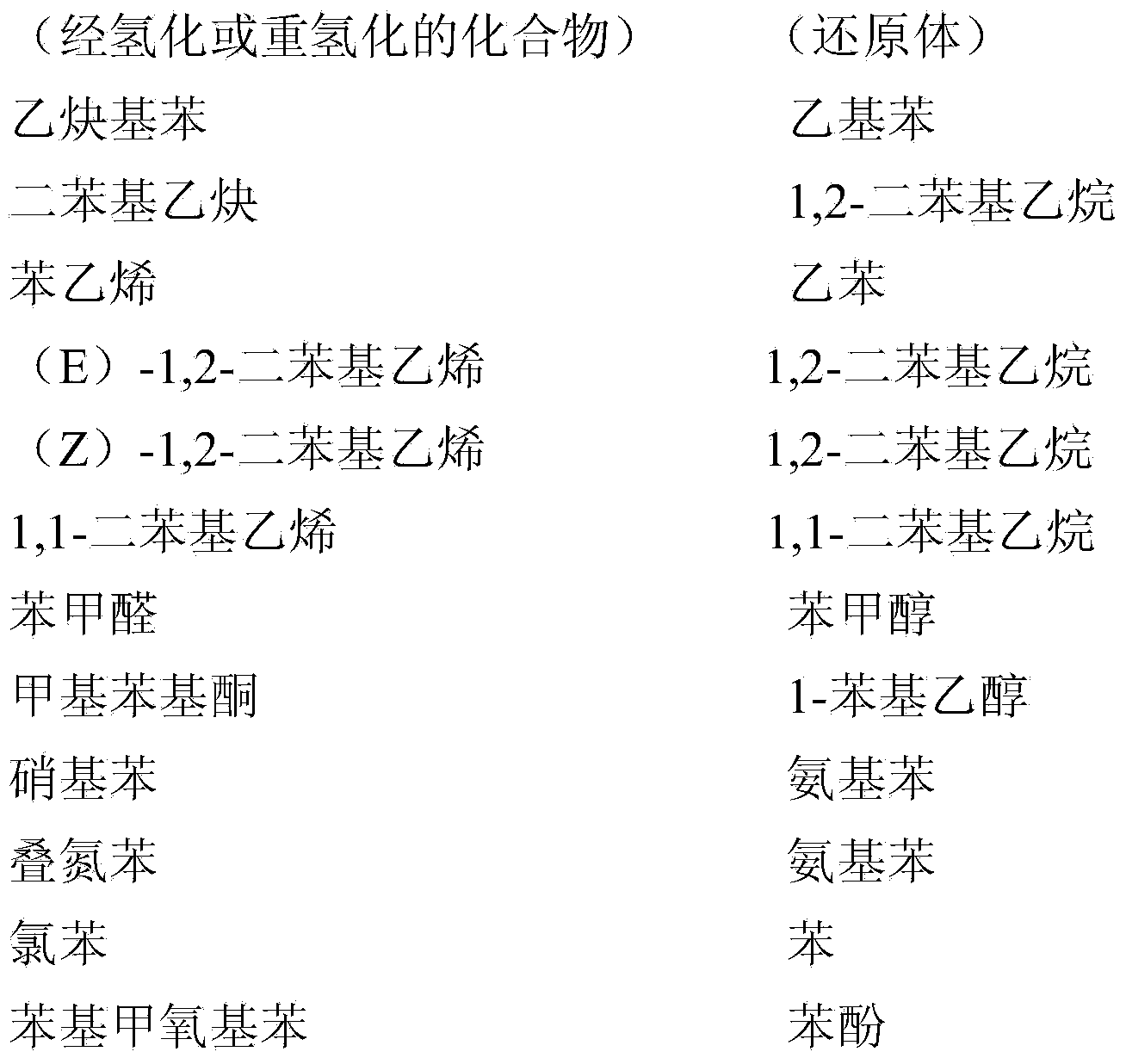

Image

Examples

Embodiment 1

[0095] Machine used: planetary ball mill made by German FRITSCH company

[0096] premium line-7

[0097] Rotation:revolution ratio=1:-2

[0098] Revolution radius 0.07m

[0099] Container: inner capacity 80mL

[0100] Material Stainless steel (SUS304)

[0101] Radius 0.0240m

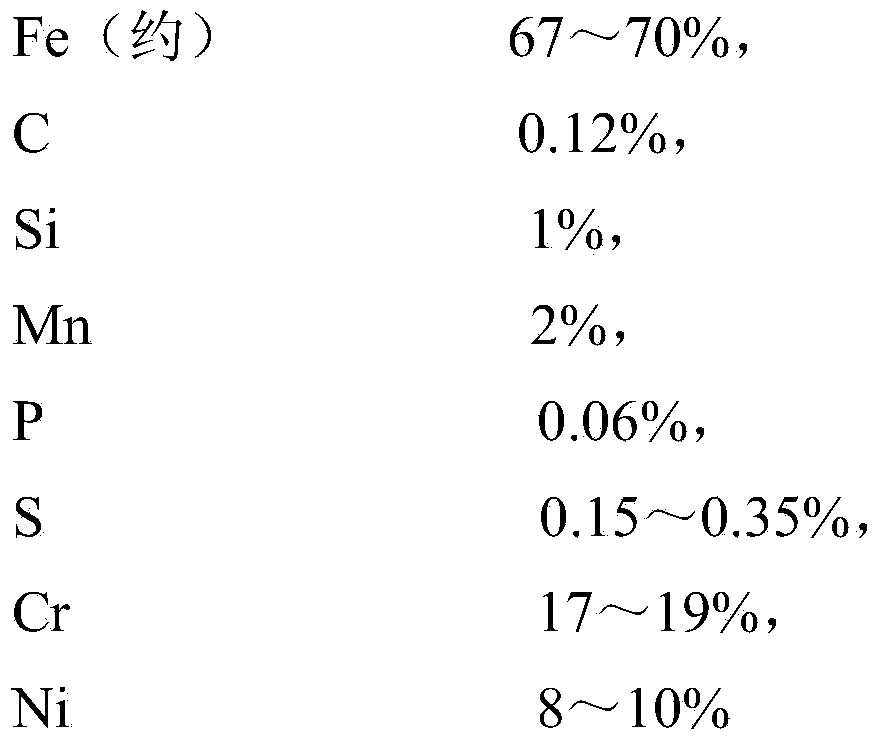

[0102] Composition of stainless steel (SUS304):

[0103]

Embodiment 3、5、7~12

[0105] Machine used: planetary ball mill made by German FRITSCH company

[0106] quartet P-7

[0107] Rotation:revolution ratio=1:-2

[0108] Revolution radius 0.067m

[0109] Container: Inner capacity 12mL

[0110] Material Stainless steel (SUS304)

[0111] Radius 0.0130m

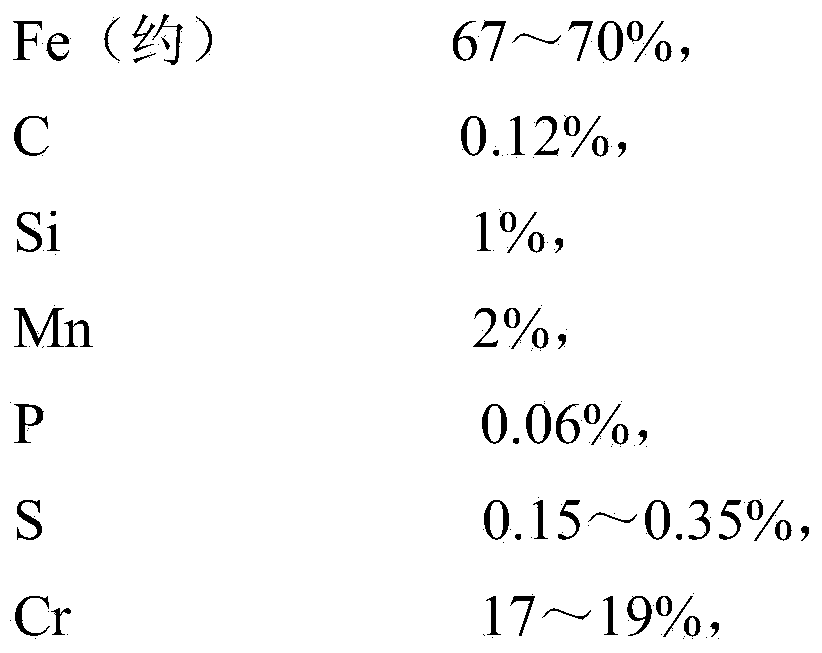

[0112] Composition of stainless steel (SUS304);

[0113]

[0114]

[0115] [mathematical formula 1]

[0116] Gn 1 = [ rs - { rp 1 · rp 1 rs · ( 1 + iw ) 2 > } ] · ( 2 · π · rpm 60 ) ...

Embodiment 2

[0132] The crafting of the ball with palladium added:

[0133] In a stainless steel (SUS304) ball (diameter 5-6 mm) (hereinafter, sometimes referred to as "SUS ball") used in a planetary ball mill, a hole with a diameter of 1 mm and a depth of 1 mm was drilled, and A palladium wire having a diameter of 1 mm and a length of 1 mm was embedded therein to obtain a palladium-added ball (hereinafter, the ball may also be referred to as "Pd ball").

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com