Launch and recovery techniques for submersible vehicles and other payloads

A material and thruster technology, applied to underwater ships, transportation and packaging, clockwork mechanisms, etc., can solve problems such as inability to compensate for surface ship fluctuations, and achieve the effect of easy positioning and ascent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

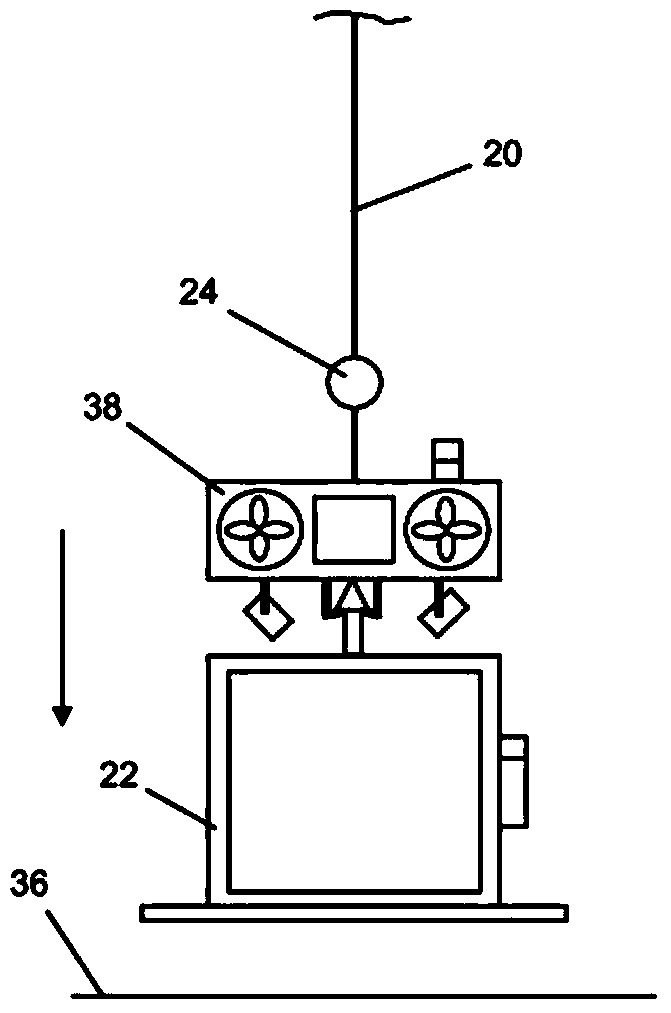

[0038] The two methods according to the present invention will be described in detail below. Both methods exemplify an AUV bank or basket delivered to the seabed, although the invention can be used with other supplies requiring delivery to or recovery from the seabed or other subsea locations, including midwater locations. In each case, the subsea location is fully submerged or below the surface such that the material is fully submerged while connected to the lift line at that location.

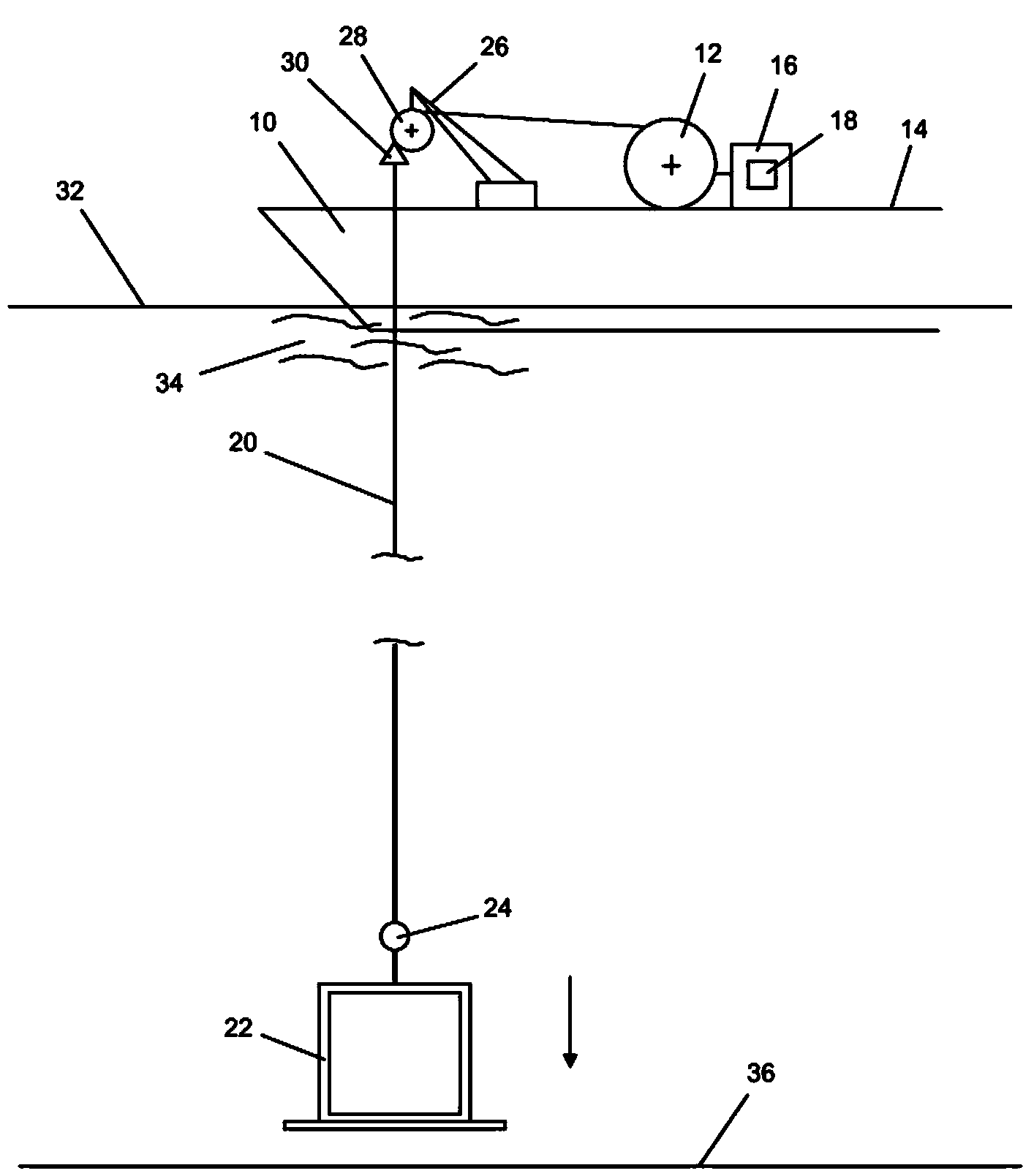

[0039] The first method leaves the materiel attached to the lift line and will refer to figure 1 The first method is described. The materiel in this example is an AUV basket that can simply launch and / or recover an AUV (not shown) during a brief stay on the seabed where the basket remains connected to a support vessel by a lift line.

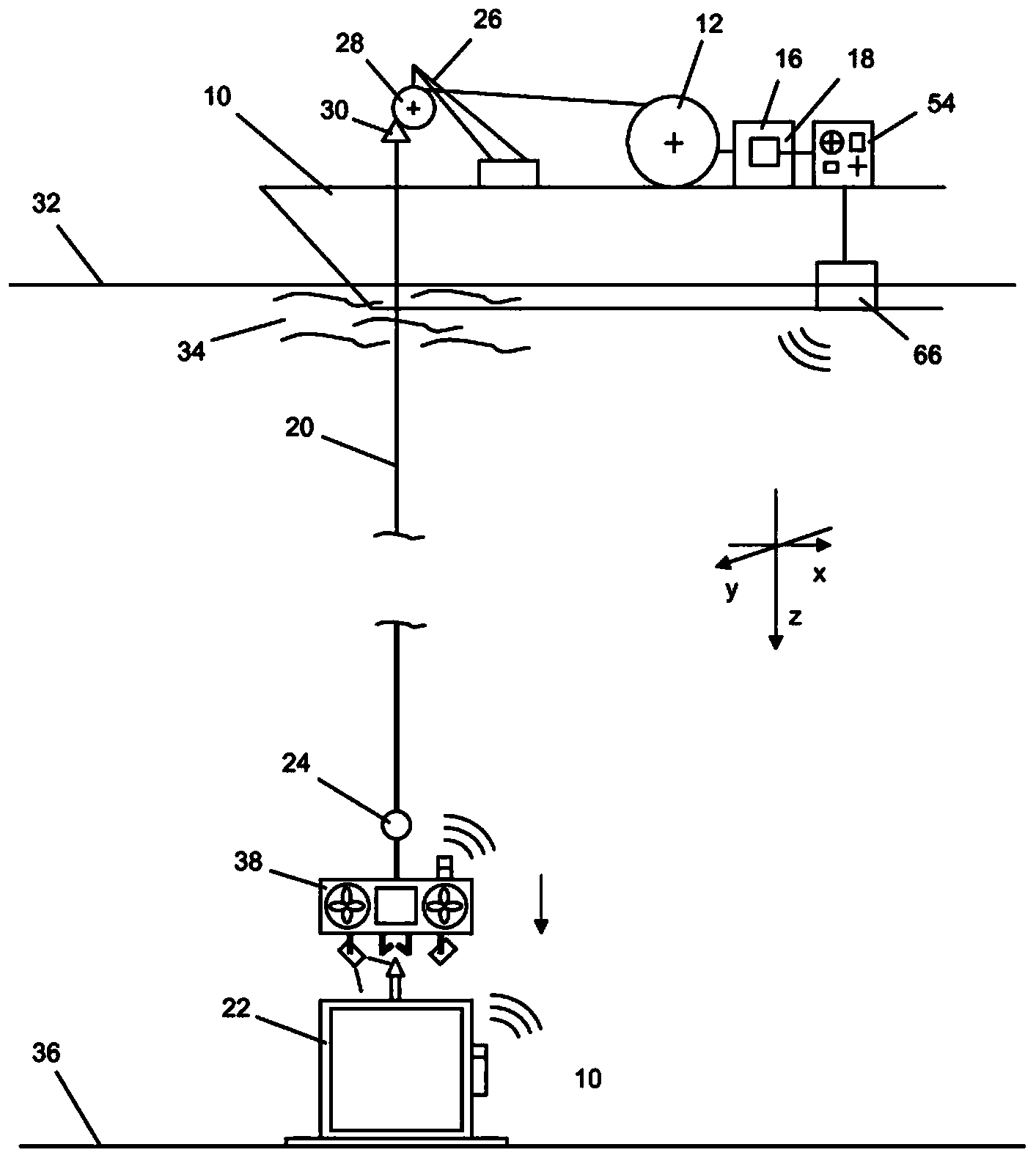

[0040] refer to Figure 2 to Figure 9 The second method described is an extension of the first method. It allows material to be left on the seabed or relea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com