High-pressure heater draining system

A high-pressure heater and water-repelling technology, which is applied in feed water heaters, lighting and heating equipment, preheating, etc., can solve the problems of increasing pump power consumption, increase steam extraction, avoid the impact of crowding, and improve safety margins Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

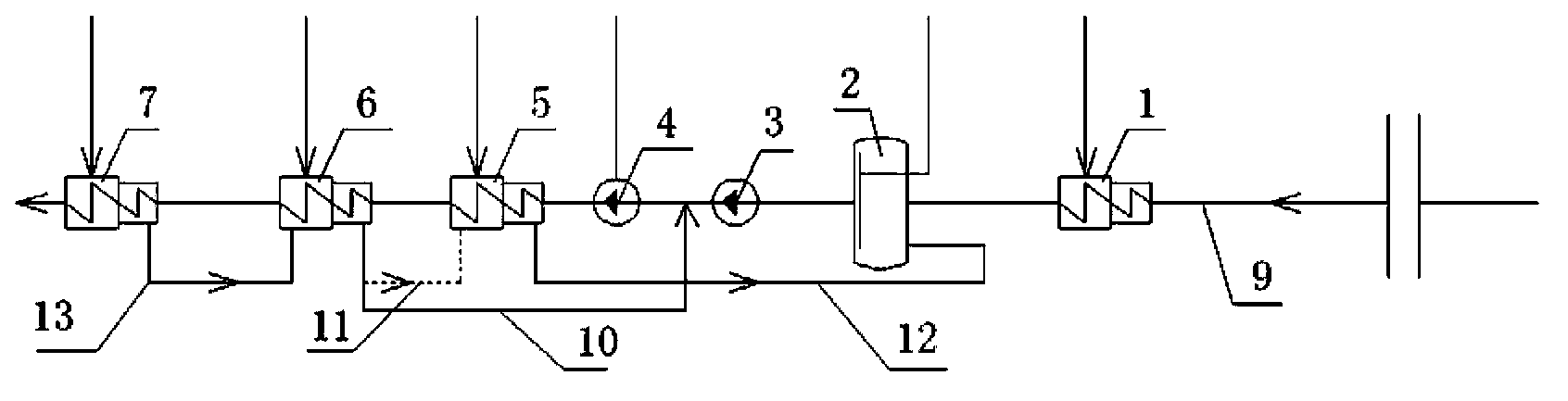

Embodiment 1

[0041] like figure 2 As shown, it is a specific embodiment of the present invention, including a low-pressure heater 1, a deaerator 2, a pre-pump 3, a feed water pump 4 and a high-pressure heater connected in sequence through a water supply pipeline 9; wherein, the high-pressure The heaters are divided into three stages, which are respectively the first stage high pressure heater 5, the second stage high pressure heater 6, and the third stage high pressure heater 7 along the feed water flow direction; the third stage high pressure heater 7 and the A drain pipeline 13 is set between the second-stage high-pressure heaters 6, and the drainage of the third-stage high-pressure heater 7 enters the second-stage high-pressure heater 6 through the hydrophobic pipeline 13; the second-stage high-pressure heating A drain pipe 10 is arranged between the device 6 and the outlet of the pre-pump 3, and the high-pressure heater 6 drains into the outlet of the pre-pump 3 through the drain pipe...

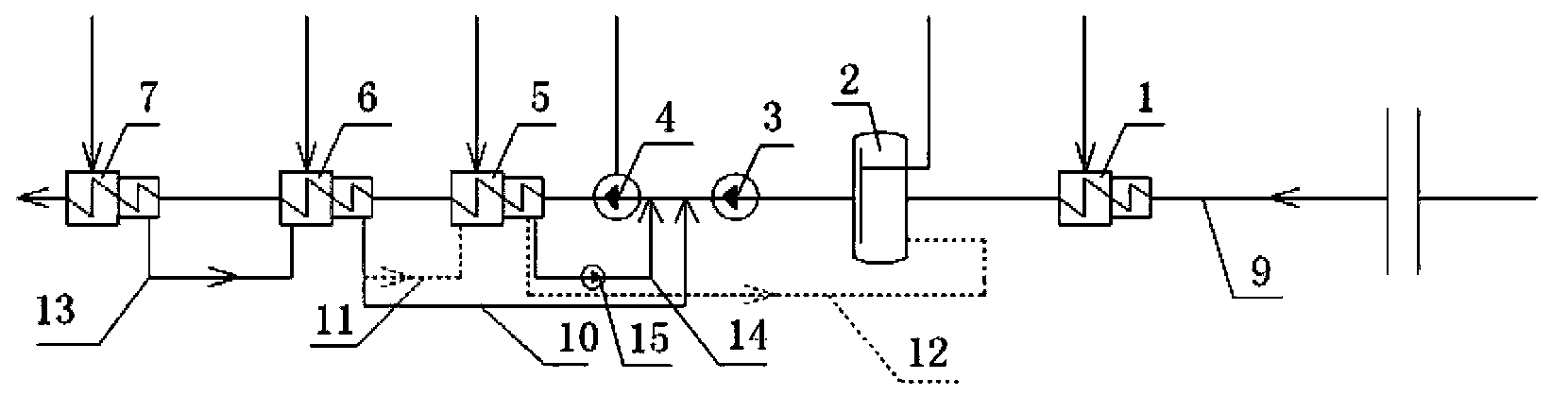

Embodiment 2

[0057] further, such as image 3 As shown, it is another specific embodiment of the present invention, including a low-pressure heater 1, a deaerator 2, a prepump 3, a feed water pump 4 and a high-pressure heater connected in sequence through a water supply pipeline 9; wherein, the The high-pressure heaters are divided into three stages, which are the first-stage high-pressure heater 5, the second-stage high-pressure heater 6, and the third-stage high-pressure heater 7 along the flow direction of the feed water. A drain pipe 13 is arranged between the third-stage high-pressure heater 7 and the second-stage high-pressure heater, and the drain of the third-stage high-pressure heater 7 enters the second-stage high-pressure heater through the drain pipe 13 6; a drain pipe 10 is arranged between the second-stage high-pressure heater 6 and the outlet of the pre-pump 3, and the drain of the second-stage high-pressure heater 6 is drained into the outlet of the pre-pump 3 through the d...

Embodiment 3

[0066] further, such as Figure 4 As shown, it is another specific embodiment of the present invention, including a low-pressure heater 1, a deaerator 2, a prepump 3, a feed water pump 4 and a high-pressure heater connected in sequence through a water supply pipeline 9; wherein, the The high-pressure heaters are divided into three stages, which are respectively the first-stage high-pressure heater 5, the second-stage high-pressure heater 6, and the third-stage high-pressure heater 7 along the feed water flow direction; the third-stage high-pressure heater 7 and the A drain pipe 13 is arranged between the second-stage high-pressure heater 6, and a drain pipe 11 is arranged between the second-stage high-pressure heater 6 and the first-stage high-pressure heater 5; The hydrophobicity of the high-pressure heater 7 enters the second-stage high-pressure heater 6 through the hydrophobic pipeline 13, and the hydrophobic mixture after the corresponding extraction and condensation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com