Assembled-type workshop wallboard and upright connecting structure

A connecting structure and assembly technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of difficult handling of installation nodes and large spacing between steel columns, so as to improve the efficiency and quality of installation and construction, easy to adjust, reduce The effect of aerial work volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention will be further described:

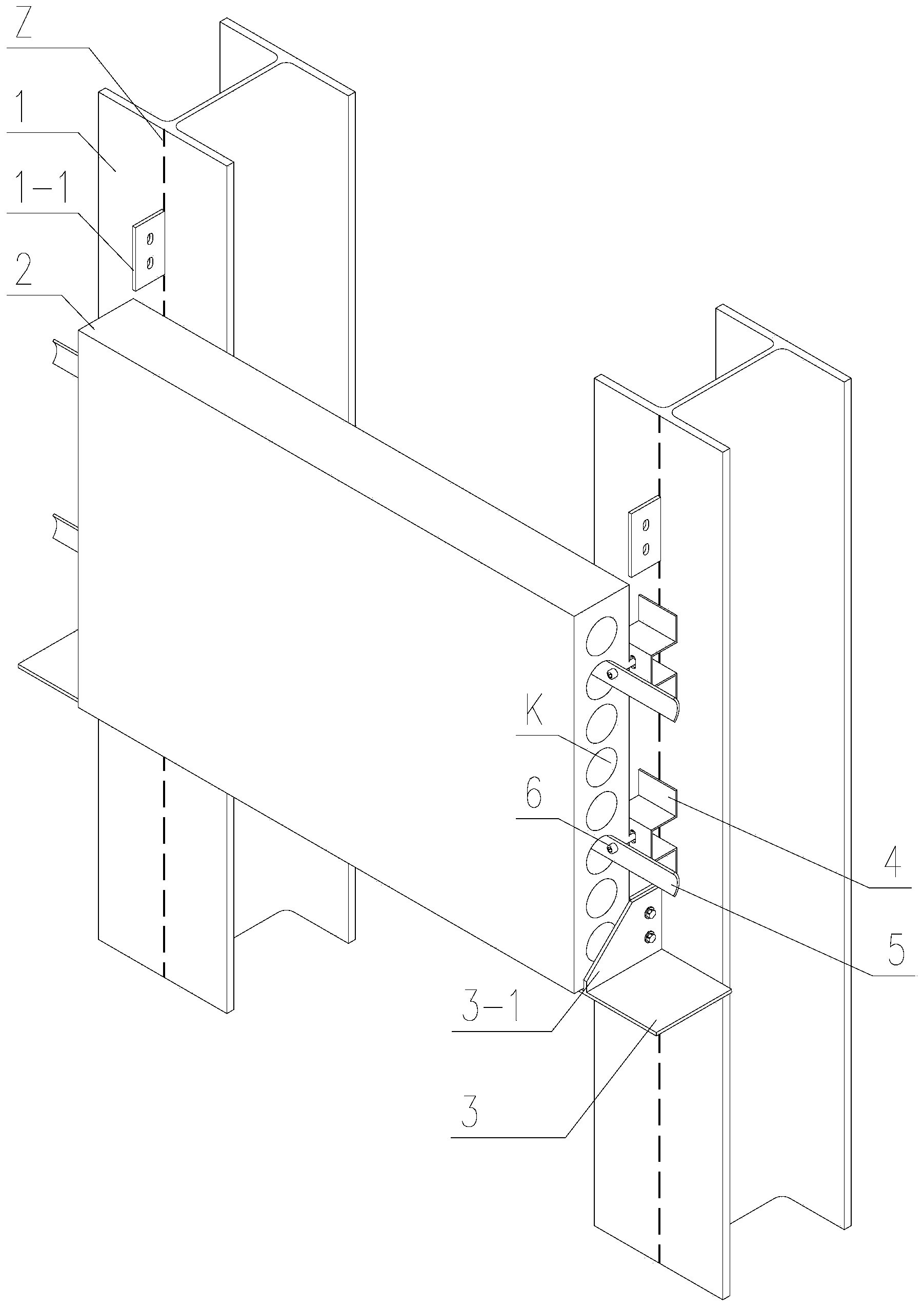

[0017] The invention relates to a connection structure between a prefabricated factory building wall panel and a column, which is composed of a column, a prefabricated unit hollow wall panel, a supporting plate, and a few-shaped pull-joint assembly. The column 1 is arranged at intervals according to the width of the prefabricated unit hollow wall panel. Positioning connecting plates 1-1 are arranged at intervals up and down, and the positioning connecting plates 1-1 are provided with vertical slots; the supporting plate 3 is bolted to the positioning connecting plate 1-1 through its vertical middle plate 3-1; the prefabricated unit The hollow wall panels 2 are vertically placed between the vertical middle plates 3-1 corresponding to the supporting plates 3 of adjacent columns; the several-shaped connectors 4 of the several-shaped pull-joint assembly are connected between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com