Buoyancy-tank type upstream control weir gate

A floating box type, floating box technology, applied in the field of floating box type upstream control weir gate, can solve the problems of energy waste, easy failure, high cost, etc., and achieve the effect of ensuring sealing, simple control, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

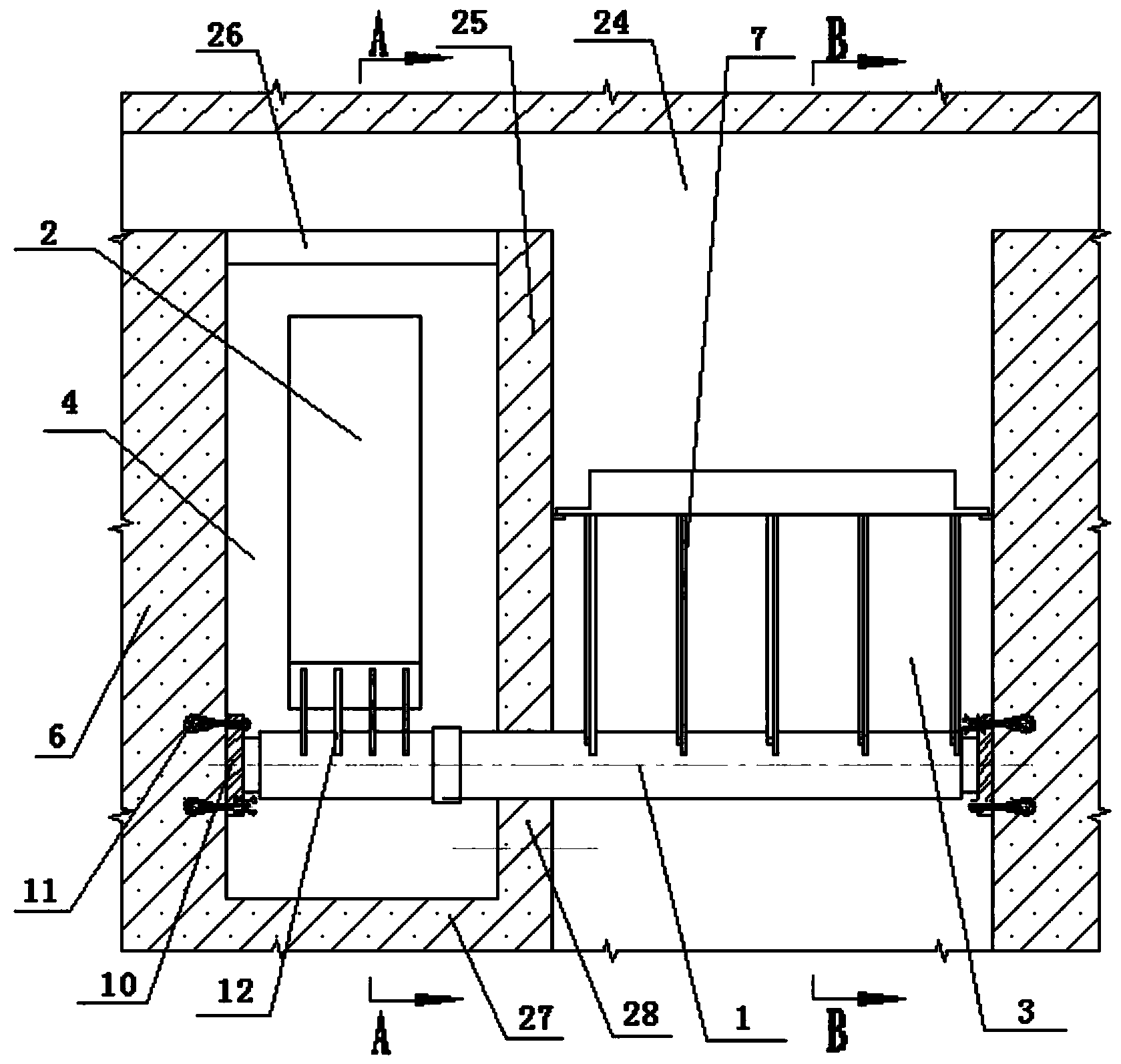

[0021] The present invention will be further described below in conjunction with accompanying drawing.

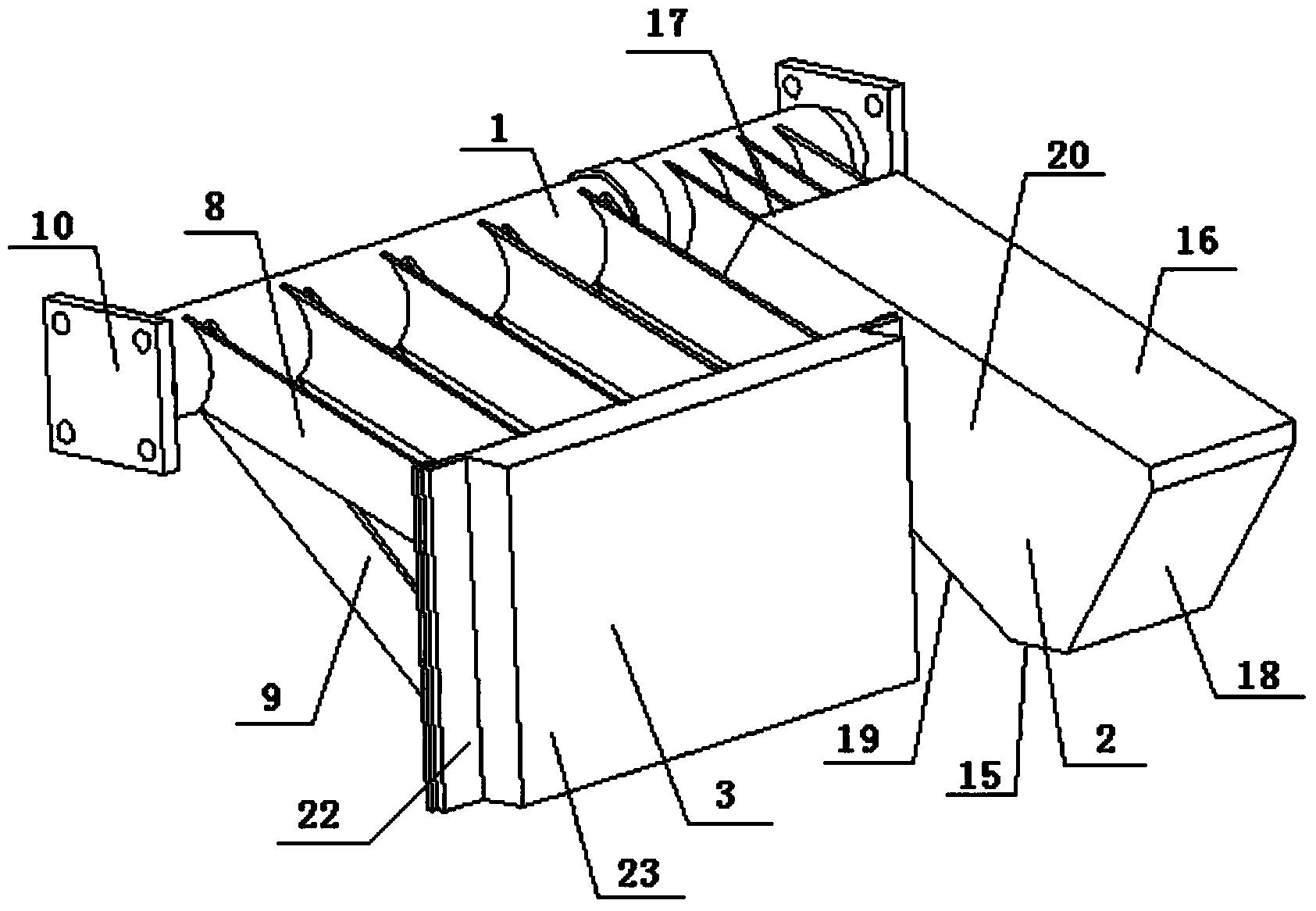

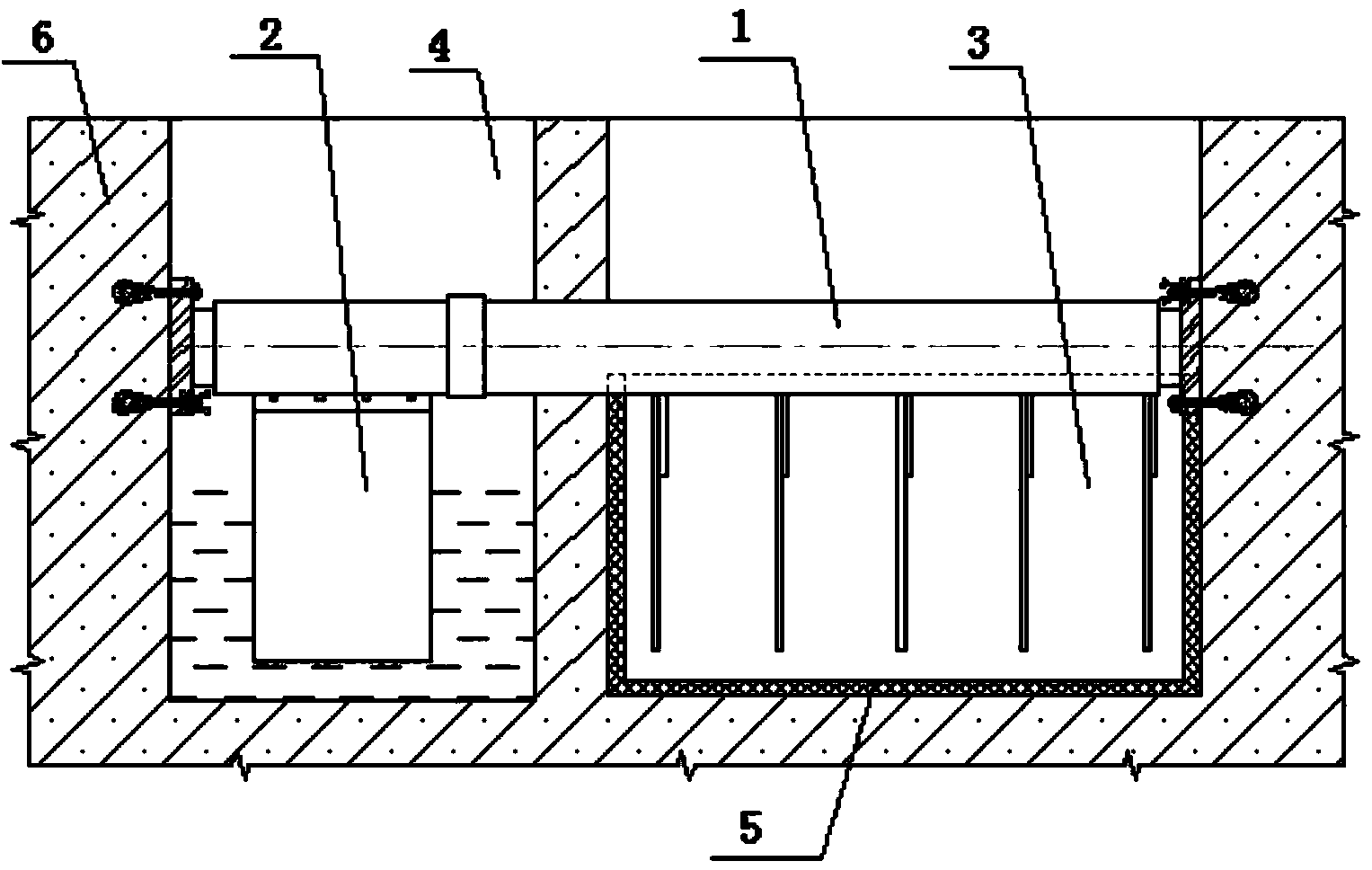

[0022] Such as image 3 As shown, the weir gate among the present invention comprises waterway 24, waterway side wall 6, weir gate plate 3, buoyancy tank 2, rotating shaft 1 and buoyancy tank chamber 4, and buoyancy tank chamber 4 is arranged in the waterway, is formed by the waterway side wall 6 The rectangular cavity surrounded by the pontoon chamber side walls 25 connected with the waterway side walls 6 on three sides, wherein the pontoon chamber side walls 25 include the front side wall 26 of the pontoon chamber, the rear side wall 27 of the pontoon chamber and the right side of the pontoon chamber. side wall 28 . A gap is provided at the top of the front side wall 26 of the floating tank chamber upstream of the rotating shaft 1, which is the water inlet 13 of the floating tank chamber, and a small gap is formed at the bottom of the right side wall 28 of the floating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com