Identifying method and device for welding joints of corrugated plates of containers and welding control system

An identification method and identification device technology, which are applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problem of not being suitable for high-precision, high-speed welding fields, detection accuracy, and the impact of droplet transition form spatter, which cannot be accurately obtained. Welding seam spatial position change and other problems, to achieve the effect of accurate detection and identification, ensure the overall welding quality, and smooth transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0021] Weld identification method

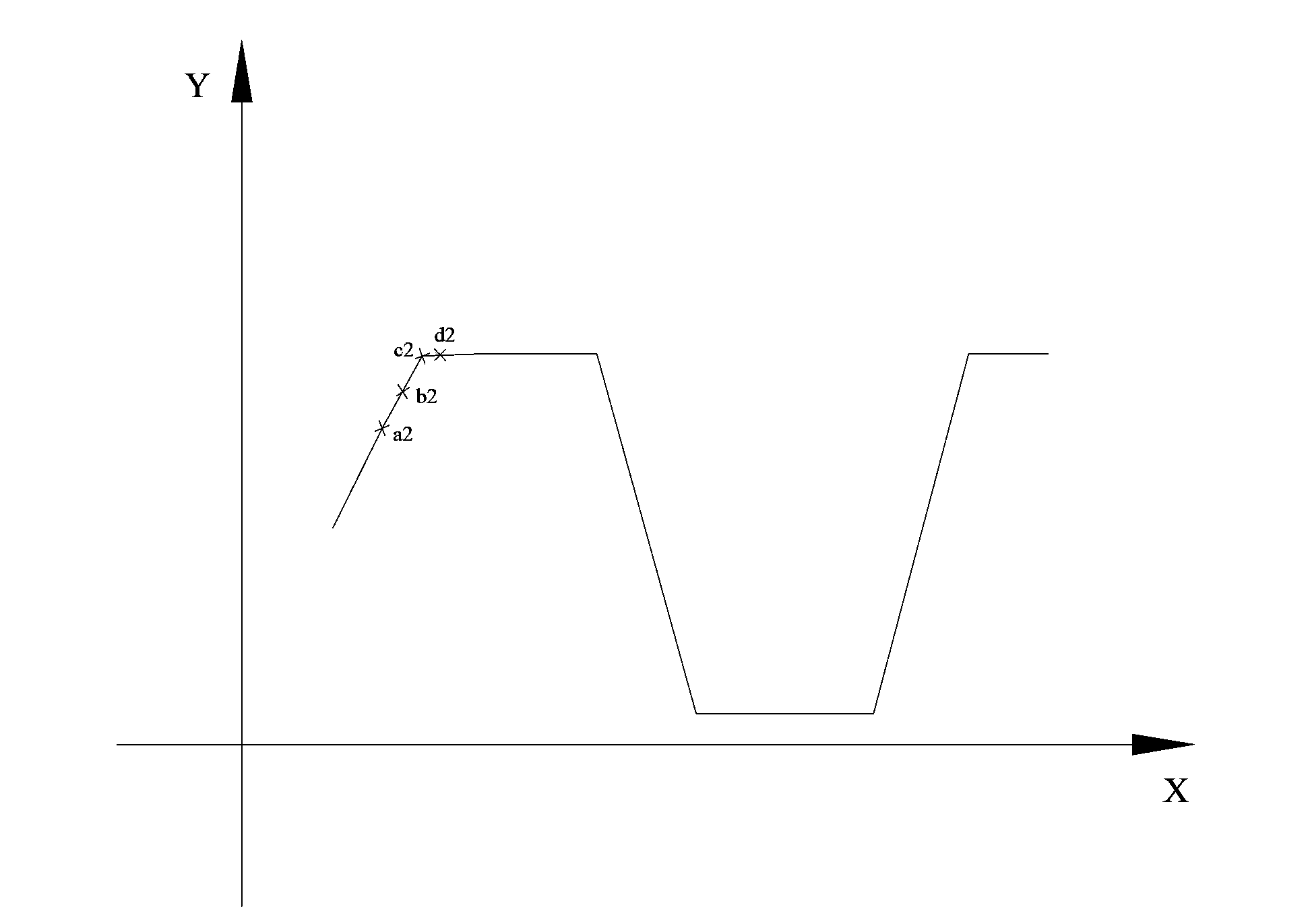

[0022] The welding seam identification method of the container corrugated plate of the present invention mainly utilizes the surface laser generator to generate the surface laser, which is projected on the welding seam, so that the laser line is offset at the welding seam, and the offset can indirectly reflect the trajectory and the welding seam. Size, through the industrial image sensor to obtain the offset laser line information to calculate the trajectory and size of the weld.

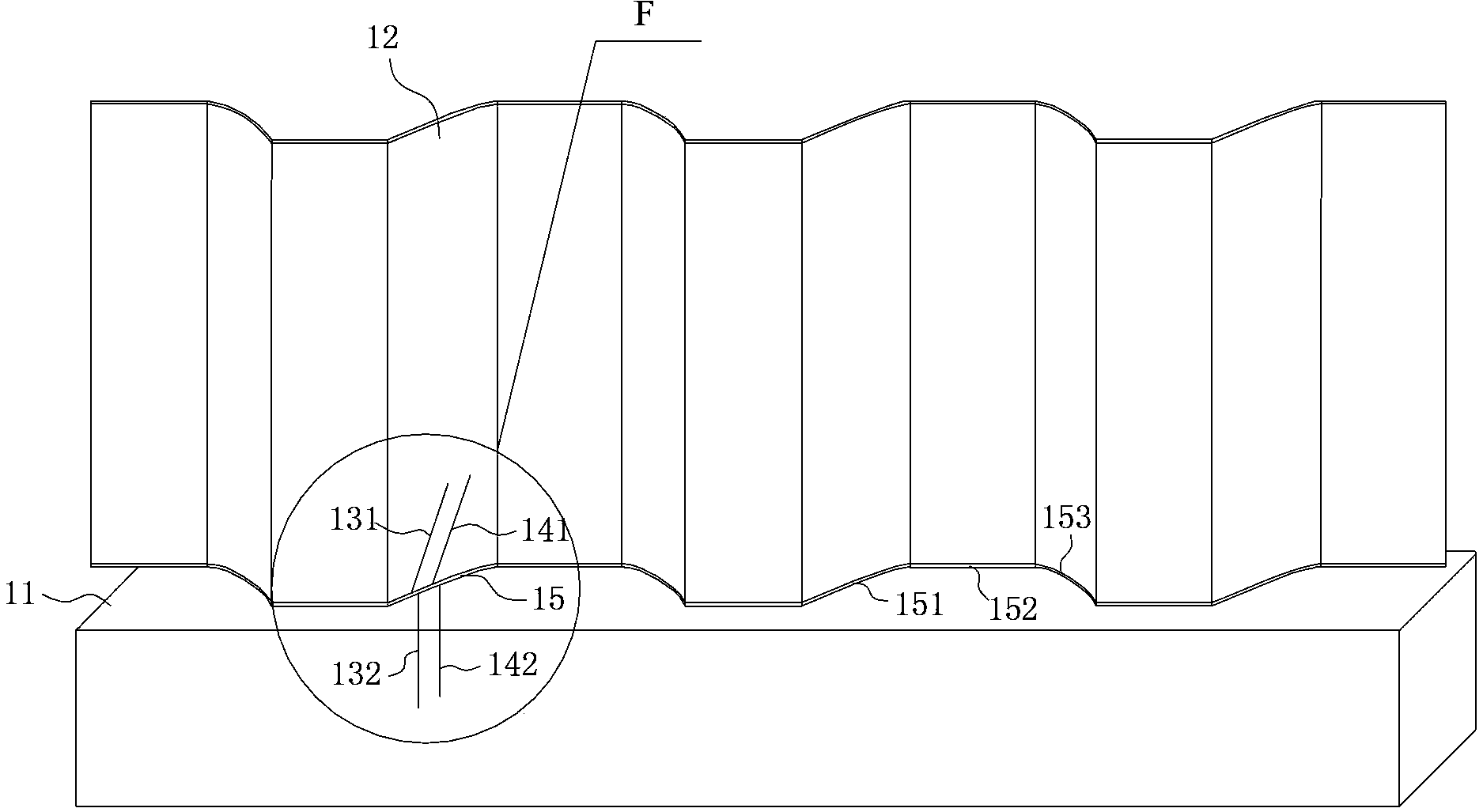

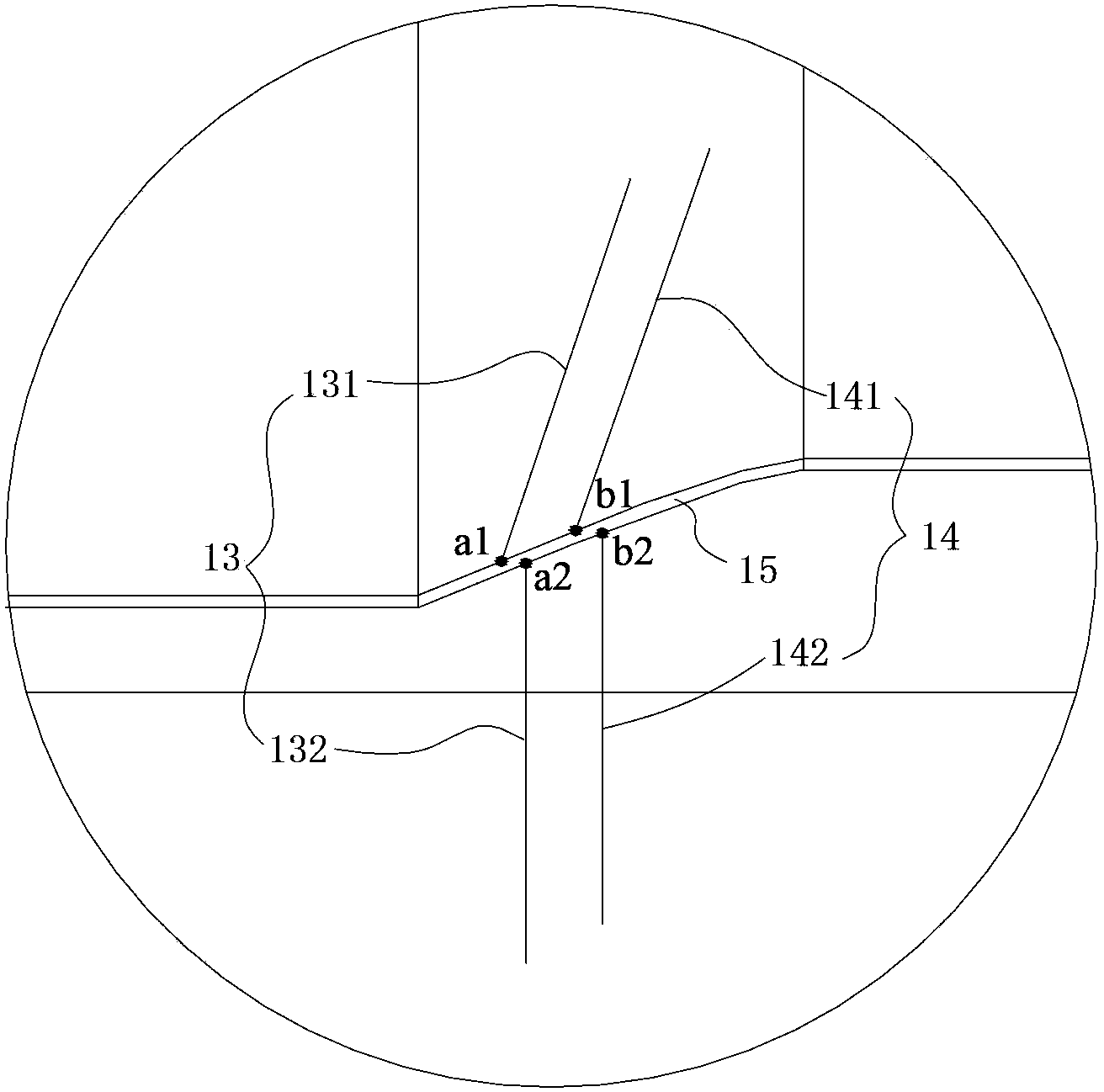

[0023] The following combination figure 1 and figure 2 The method for identifying the weld seam of the container corrugated plate is described in detail. In the figure, a weld seam 15 is formed at the joint between the corrugated plate 12 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com