A fast tensioning device for vibrating screen mesh

A technology of tensioning device and sieve mesh, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of wasting labor, increasing labor intensity of workers, large deformation, etc., so as to improve tensioning efficiency and save labor. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

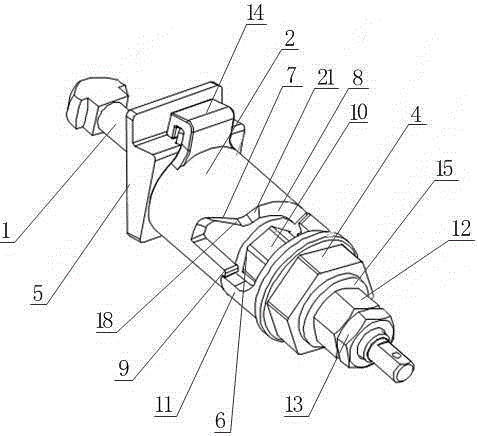

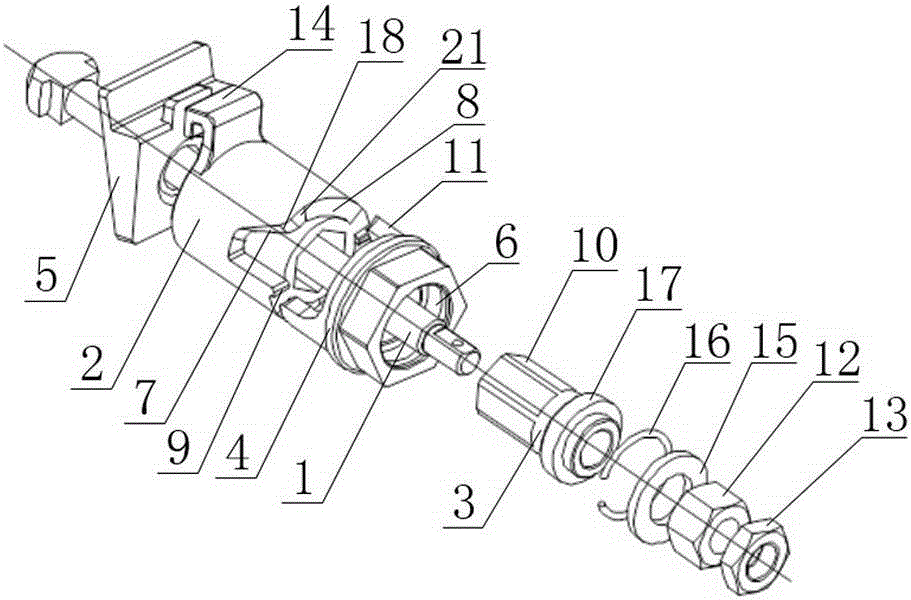

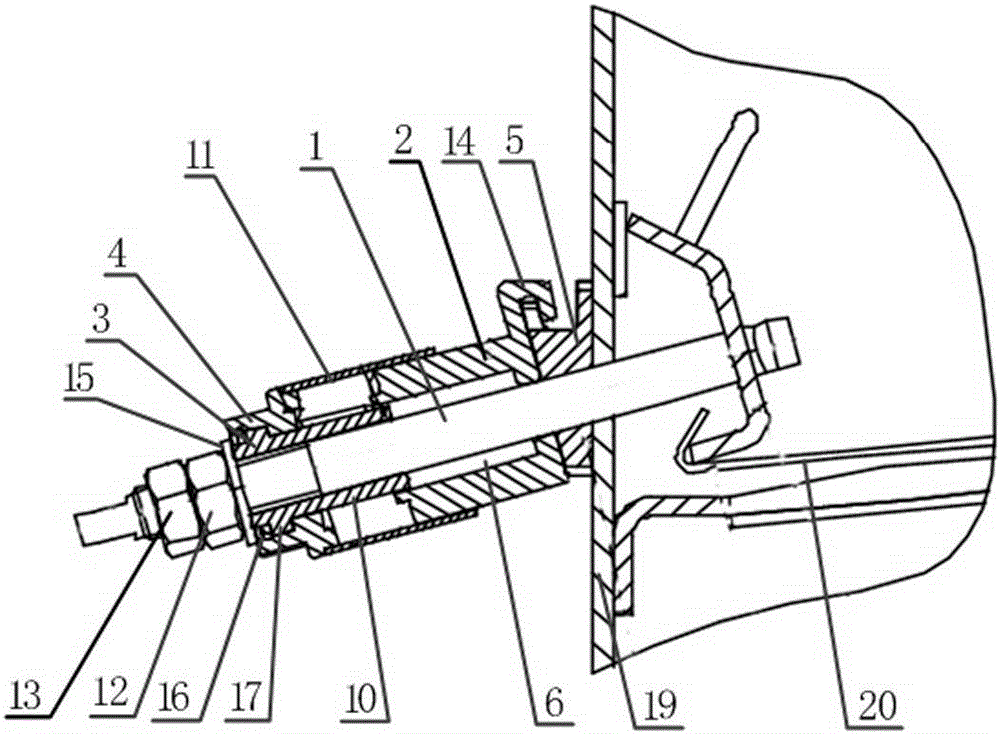

[0016] Such as figure 1 , figure 2 , Figure 4 As shown, a quick tensioning device for a vibrating screen includes a tensioning bolt 1, an end face cam 2, a stress sleeve 3, a rotating head 4, a steel wire retaining ring 16, a flat washer 15, an adjusting nut 12 and a lock nut 13. The front end of the tensioning bolt 1 passes through the end cam 2, the bearing sleeve 3 and the flat washer 15 in turn. The end cam 2 has a hexagonal guide hole 6 in the center, and one end of the bearing sleeve 3 is an outer hexagonal column 10. The outer hexagonal column 10 is placed in the guide hole 6, the force sleeve 3 is set on the tension bolt 1 and the other end of the force sleeve 3 is assembled in the inner hole of the rotation head 4, and the end of the force sleeve 3 Ring-shaped ribs 17 are provided, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com