Tension support mechanism of compact spinning device

A tension and support seat technology, applied in spinning machines, textiles and papermaking, drafting equipment, etc., can solve the problems of poor grid tensioning efficiency, unable to fully achieve yarn hairiness strength, and long slack parts, etc. The effect of improving the tensioning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

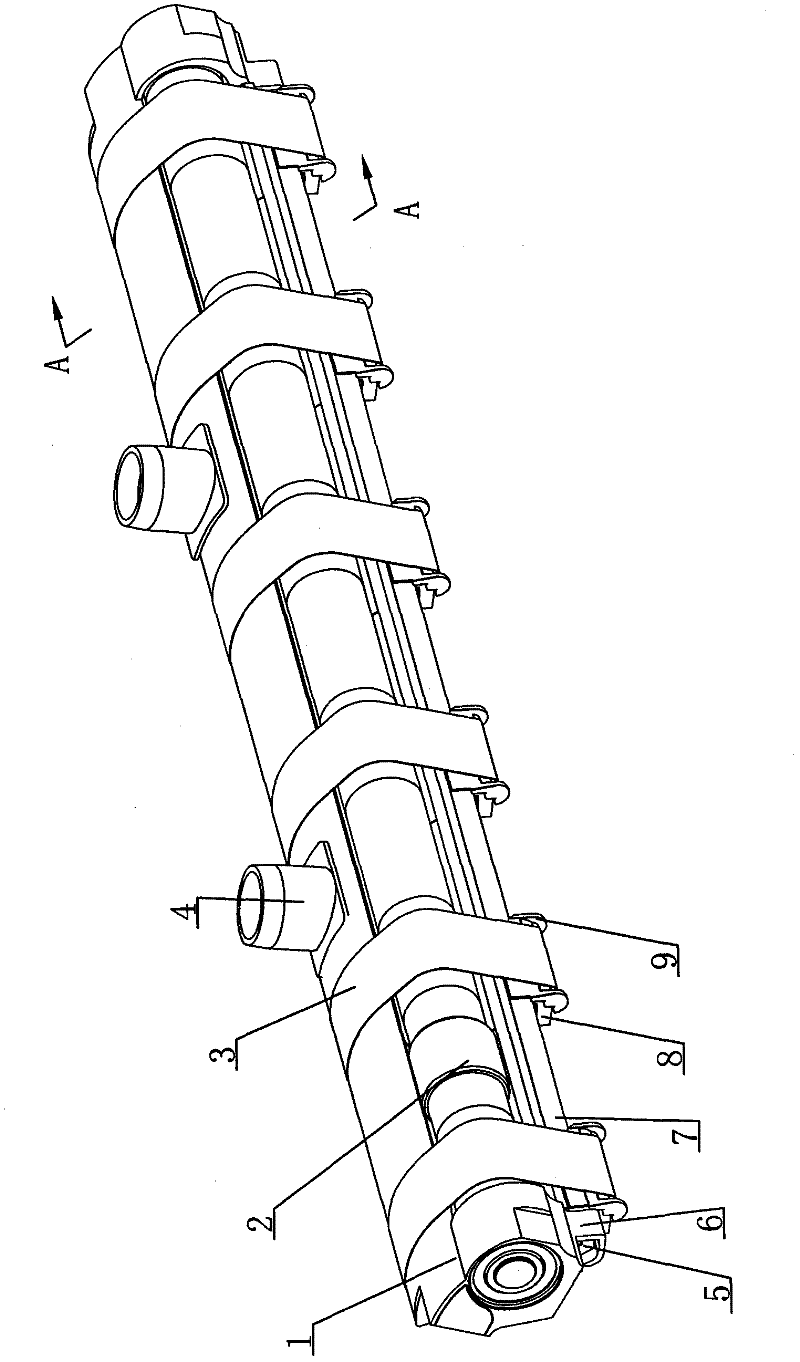

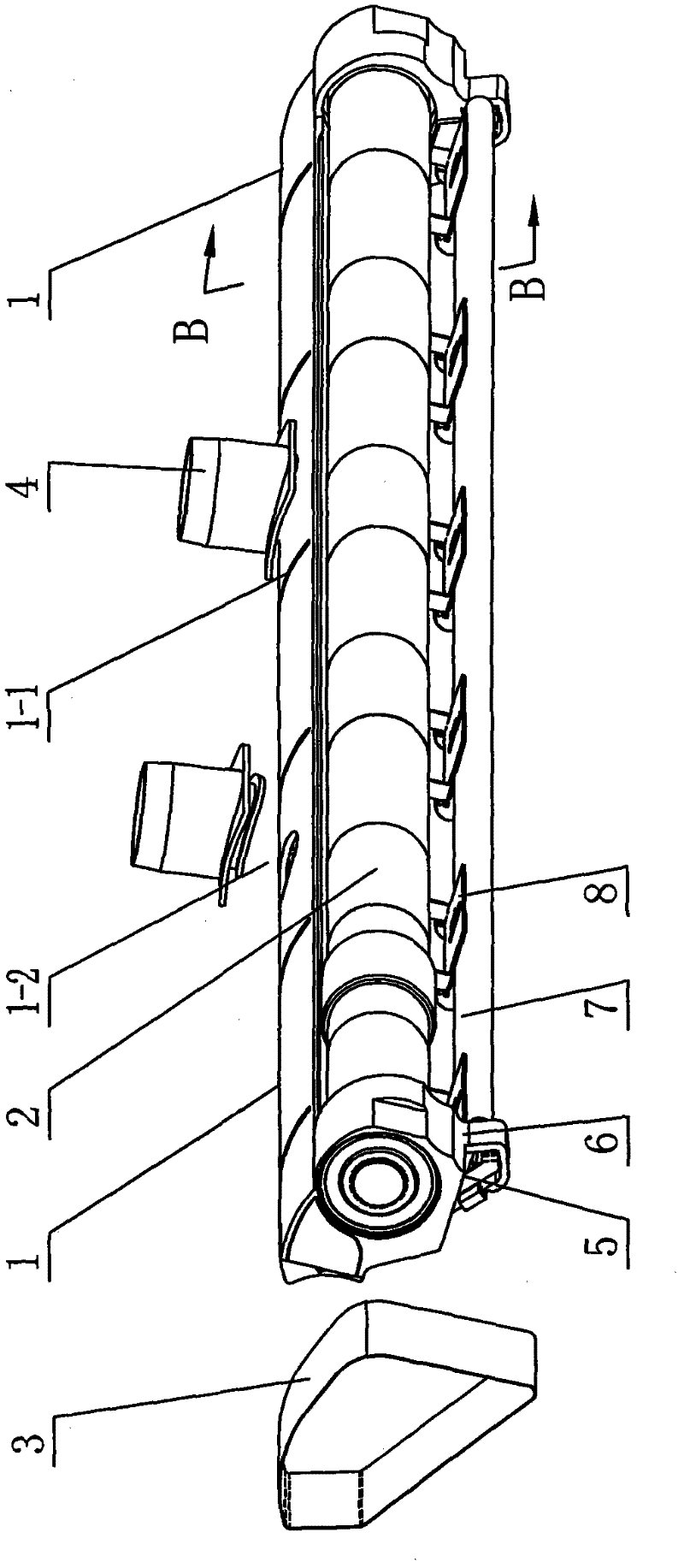

[0024] See Figure 1-13 As shown, the tension support mechanism of the compact spinning device of the present invention includes two tension support seats 6 arranged on the lower side of the negative pressure accumulation tube, a tension support frame and two positioning spring pieces 5, and two tension support seats 6 are provided with installation hole. See Figure 1~5 As shown, the two tension support seats 6 of the present invention are located at the lower side of the negative pressure accumulation pipe 1, the tension support seats 6 are fixed on the bottom of the negative pressure accumulation pipe 1, and the two tension support seats 6 and the negative pressure accumulation pipe 1 are made into an integral structure. At least one suction hole 1-2 and more than three airflow guide grooves 1-1 communicated with the negative pressure chamber are provided on the tube wall of the negative pressure accumulation pipe along the guide surface, and the suction joint 4 is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com