Auger assembly

An assembly and auger technology, which is applied in the field of solid-liquid separation and dehydration devices, can solve the problems that the position and structure rationality of the disassembly and cooperation ability needs to be improved, and the working ability is backward, and achieves improved work quality, easy disassembly and cleaning, and fine coordination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0014] Please refer to the attached Figures 1 to 3 , the embodiment of the present invention includes:

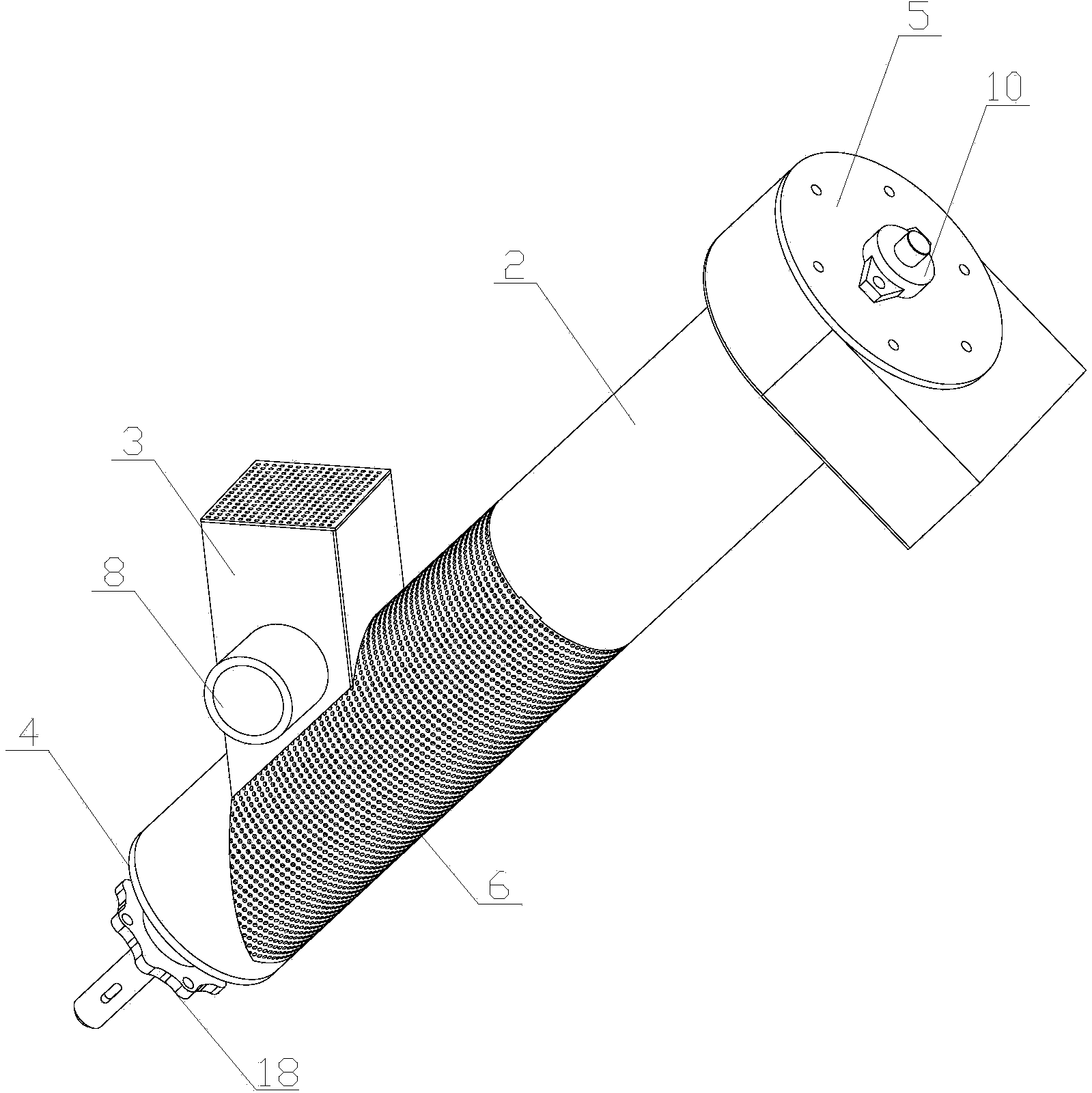

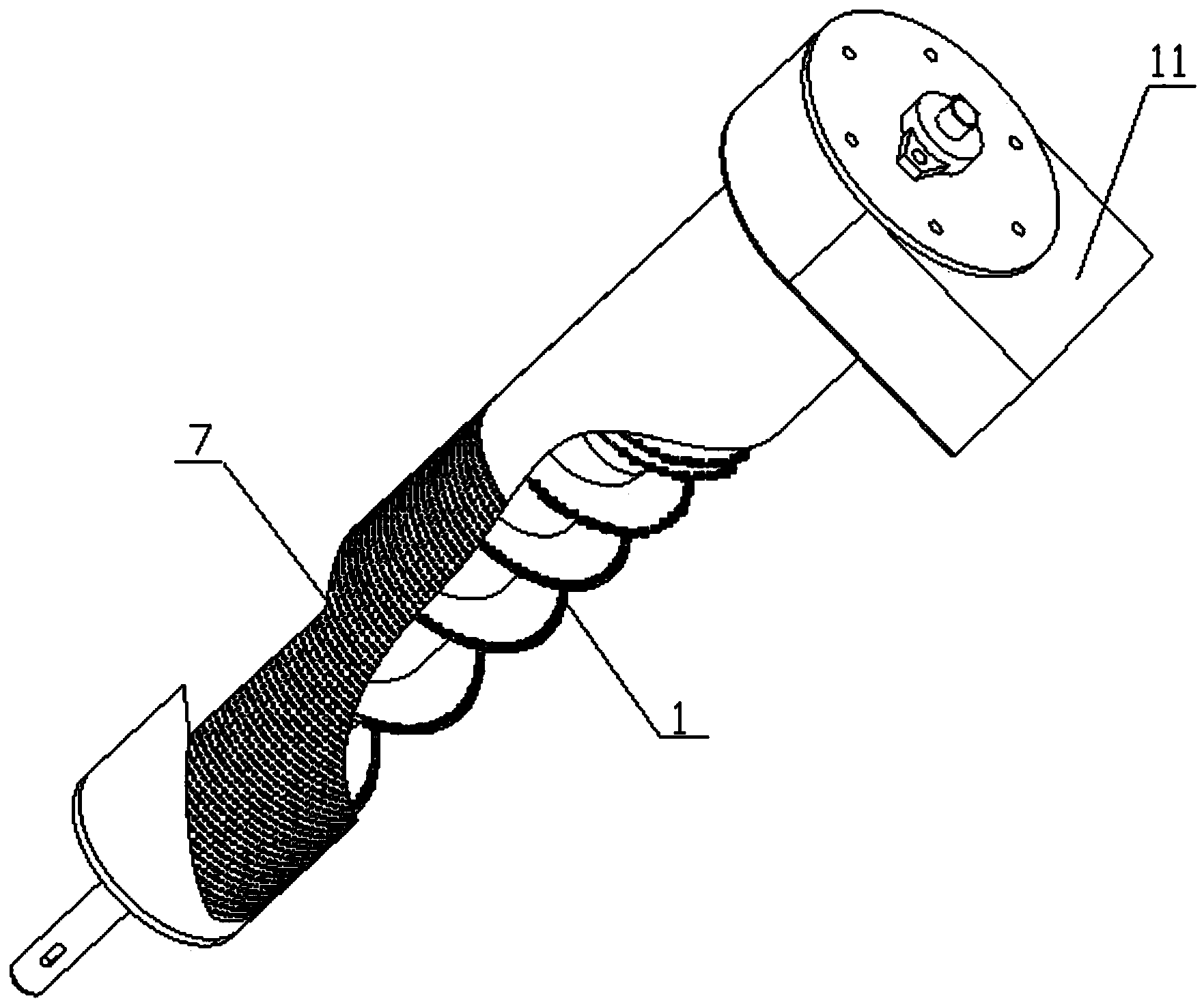

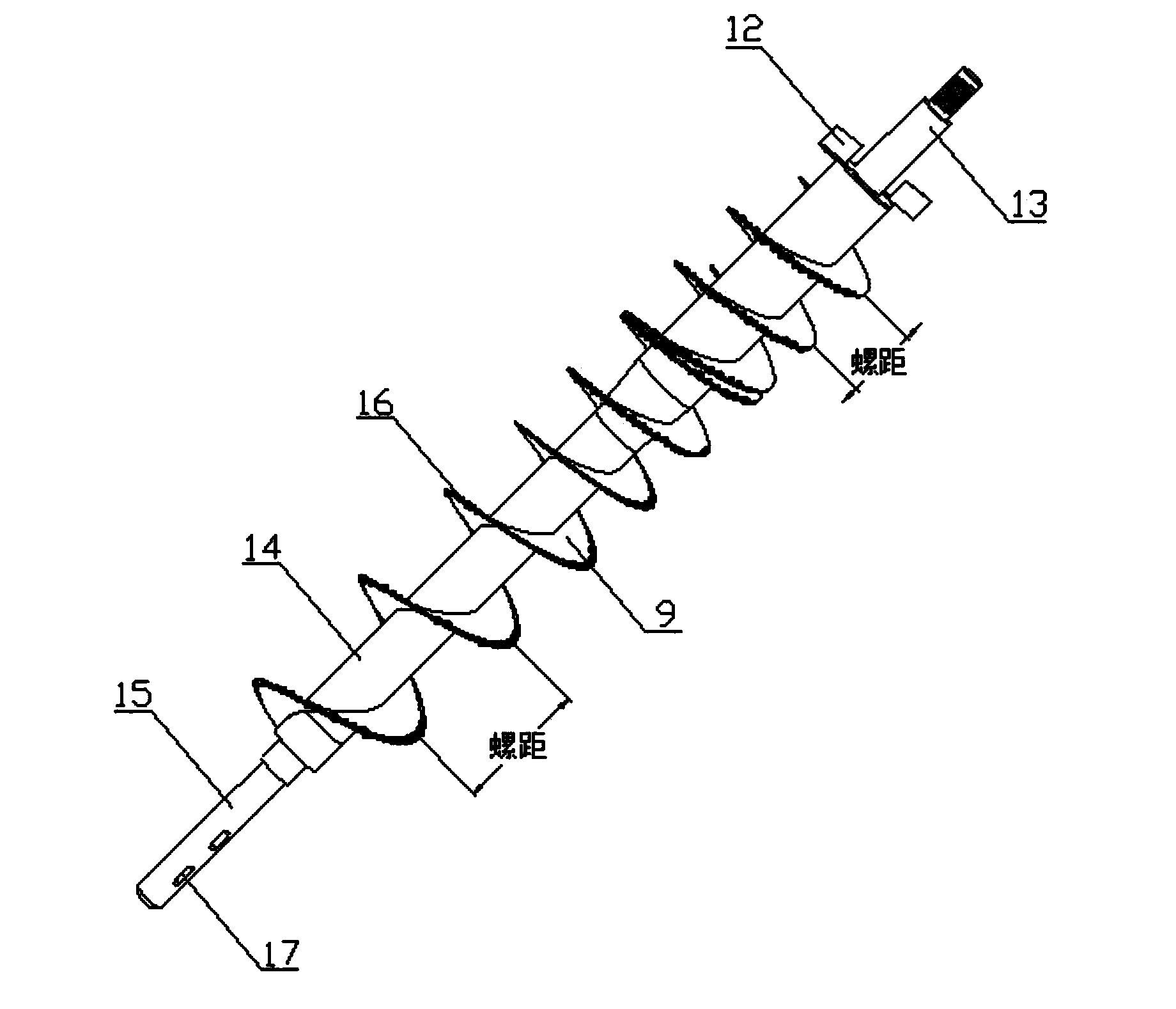

[0015] Such as figure 1 , an auger assembly, which includes a screw auger 1, a filter cartridge 2 and a connecting net cover 3. Wherein, the filter cartridge 1 is a cylindrical hollow container, the bottom of the filter cartridge 2 is equipped with a sealed bearing end cap 4 , and the upper end of the filter cartridge 2 is equipped with a movable end cap 5 . The outer surface of the lower part of the filter cartridge 2 is evenly arranged with fine and dense meshes 6, and the outer surface with the meshes 6 is provided with a feed port 7 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com