Two stage technology for hardening and combining lenses

A lens and process technology, applied in the field of two-stage hardening operation, can solve the problems of lens strain, glue opening, air bubbles, etc., to achieve the effect of improving image quality, superior optical performance, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

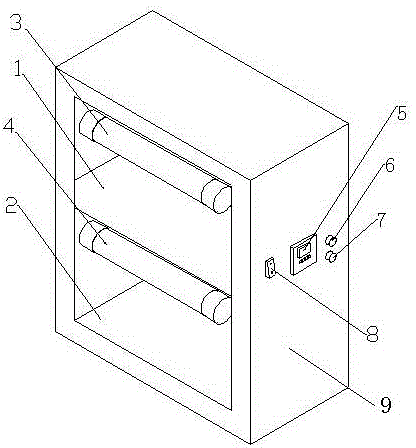

Image

Examples

Embodiment Construction

[0014] A two-stage hardened cemented lens process comprising the steps of:

[0015] 1. Lens lamination: Firstly, wash the lens baskets and put them directly on the assembly line for lamination, then glue the appearance, and cure the two lenses for centering to ensure the accuracy of the cores, and then perform temporary hardening to prevent the centering from being centered. Then wipe away glue spills and surface stains for maximum cleanliness before formally hardening to prevent arching of shiny lines.

[0016] 2. Secondary curing procedure: set the illuminance according to three technical standard sections:

[0017] The first standard section: it is stricter for parts of Yasi , and the outer diameter is more than ; the illumination is set to 1500-2000um / cm 2 ;

[0018] The second standard section: for parts Yas is more strict than , and the outer diameter is ; the hardening time is 1-3 hours; the structural illumination is set at 4800-7500um / cm 2 ;

[0019] The third sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com