Water pump assembly for diesel engine

A water pump and assembly technology, which is applied in the field of water pump assembly of diesel engines, can solve the problems of large volume of water pump assembly, volute fit clearance, large liquid flow resistance, etc., and achieve reliable performance, small pressure fluctuation and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described with reference to the accompanying drawings. In the drawings of the specification, elements having similar structures or functions will be denoted by the same element symbols. The drawings are only for the convenience of illustrating various embodiments of the present invention, and are not intended to describe the present invention exhaustively, nor limit the scope of the present invention.

[0021] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

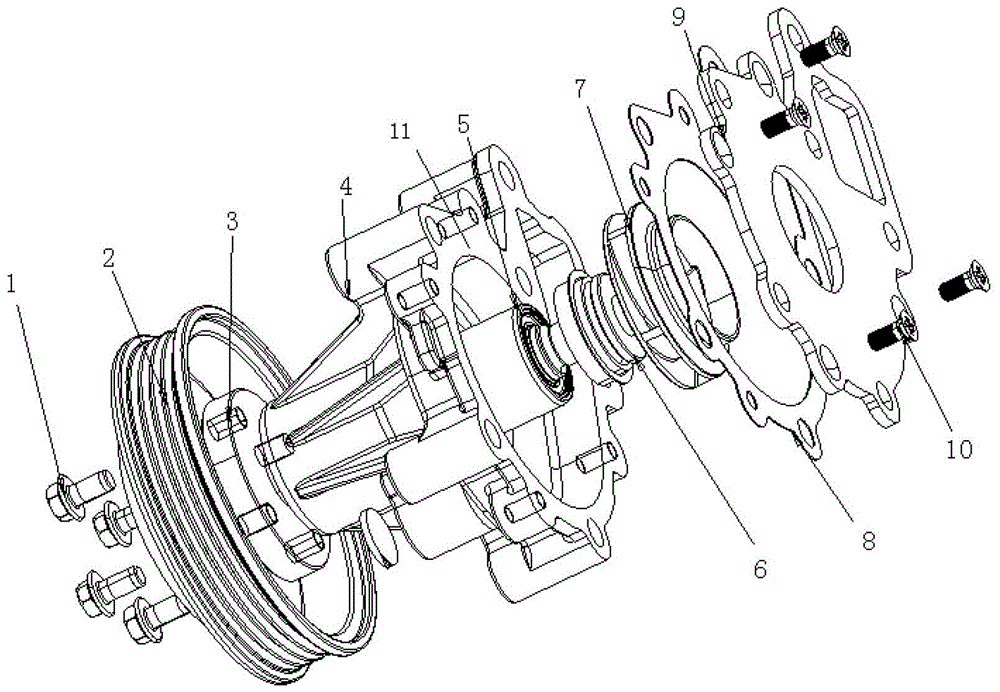

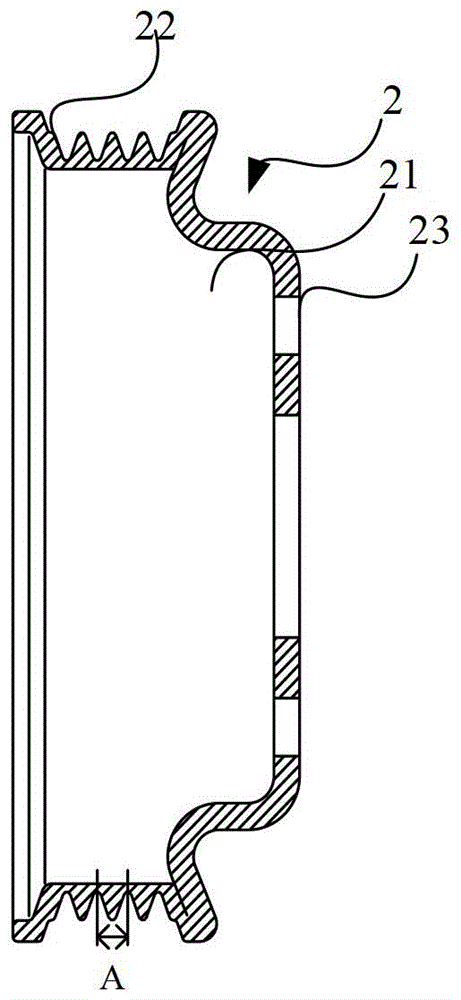

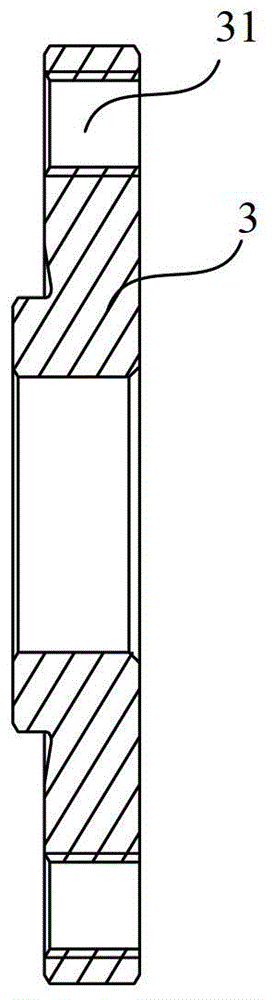

[0022] Such as Figure 1-Figure 4 As shown, the present invention is used for the water pump assembly of diesel engine, and it comprises a pulley 2, a pulley hub 3, a water pump body 4, a water seal 6 and an impeller 7 matched with the volute 11 of the water pump body 4 . Wherein, the pulley hub 3 is arranged in the pulley 2, and is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com