Abrasion-resistant alloy mortar pump cover and manufacturing method thereof

A wear-resistant alloy and mortar pump technology, which is applied to pump components, variable capacity pump components, components of a pumping device for elastic fluids, etc. Avoid thermal stress cracks and shrinkage cavities, reduce production costs, easy size effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

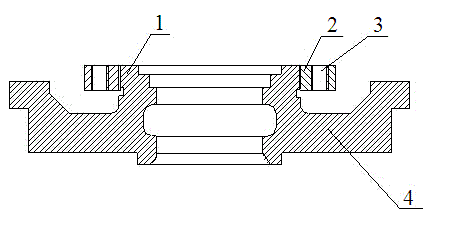

[0023] refer to figure 1 , the pump cover of this embodiment includes a cover body 4, the cover body 4 is a hollow annular structure, the edge of the cover body 4 is raised upwards to form an annular groove, and the inner edge of the cover body 4 is provided with a ring-shaped rear The outer edge of the melon 1 and the back melon 1 is provided with a ring-shaped connecting block 2, and the circumference of the connecting block 2 is uniformly provided with a static ring screw hole 3, the diameter of the static ring screw hole 3 is 11mm, the cover body 4 and the back melon 1 are all made of wear-resistant alloy, and the connecting block 2 is made of cast iron.

[0024] The manufacturing method of the pump cover of the present embodiment is as follows:

[0025] (1) Process and shape the connecting block 2; (2) Place the processed and f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com