Sectional synchronous sampling and water exploration tubular column of multi-section fracturing horizontal well and working method thereof

A technology for finding water pipe strings and working methods, which is applied in the fields of earth-moving drilling, wellbore/well components, and production fluids, etc., and can solve the problems of long water-seeking period, unsuitable for water-seeking needs, and affecting on-site production progress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

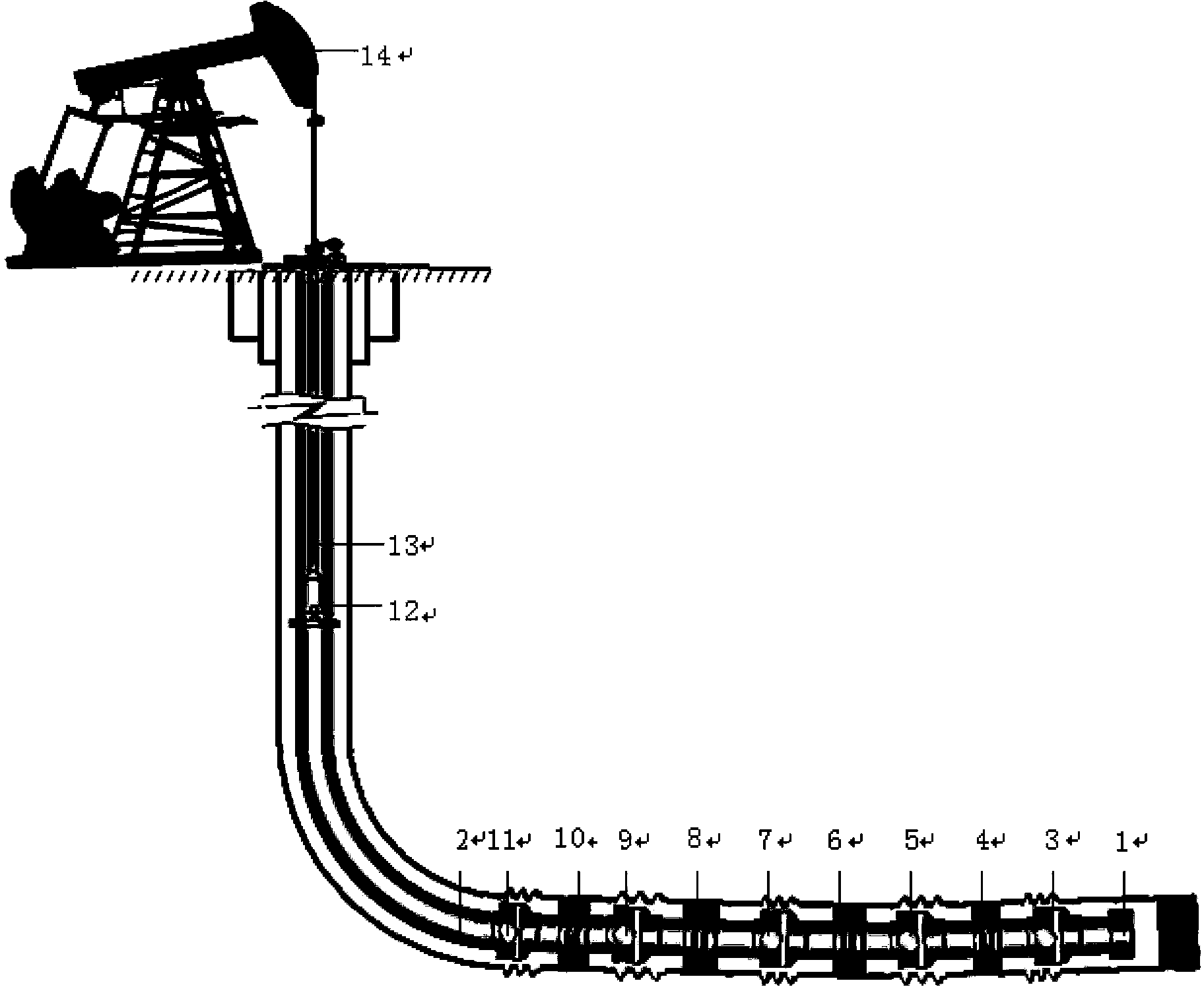

[0013] refer to figure 1 Embodiments of the present invention are further described:

[0014] Take the simultaneous sampling of water finding strings in fractured horizontal wells in five production intervals as an example:

[0015] The upper end of the plug 1 of this string is connected to the first-level downhole sampling switch 3 through the tubing 2, the upper end of the first-level downhole sampling switch 3 is connected to the first-level packer 4 through the tubing 2, and the upper end of the first-level packer 4 is connected through the tubing 2 Level II downhole sampling switch 5, the upper end of level II downhole sampling switch 5 is connected to level II packer 6 through tubing 2, the upper end of level II packer 6 is connected to level III downhole sampling switch 7 through tubing 2, level III downhole sampling The upper end of the switch 7 is connected to the stage III packer 8 through the tubing 2, the upper end of the stage III packer 8 is connected to the lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com