Hybrid drive device of motor vehicle

A hybrid drive and motor vehicle technology, applied to motor vehicles, power plants, hybrid vehicles, etc., can solve problems such as system design and coolant delay, and achieve the effects of time delay avoidance, overload avoidance, and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

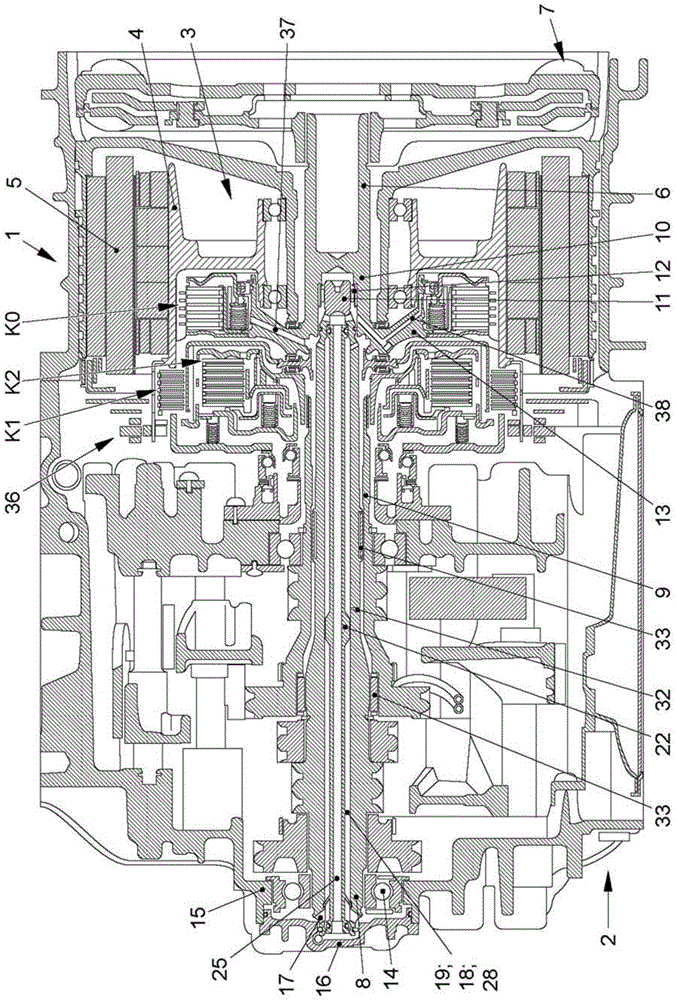

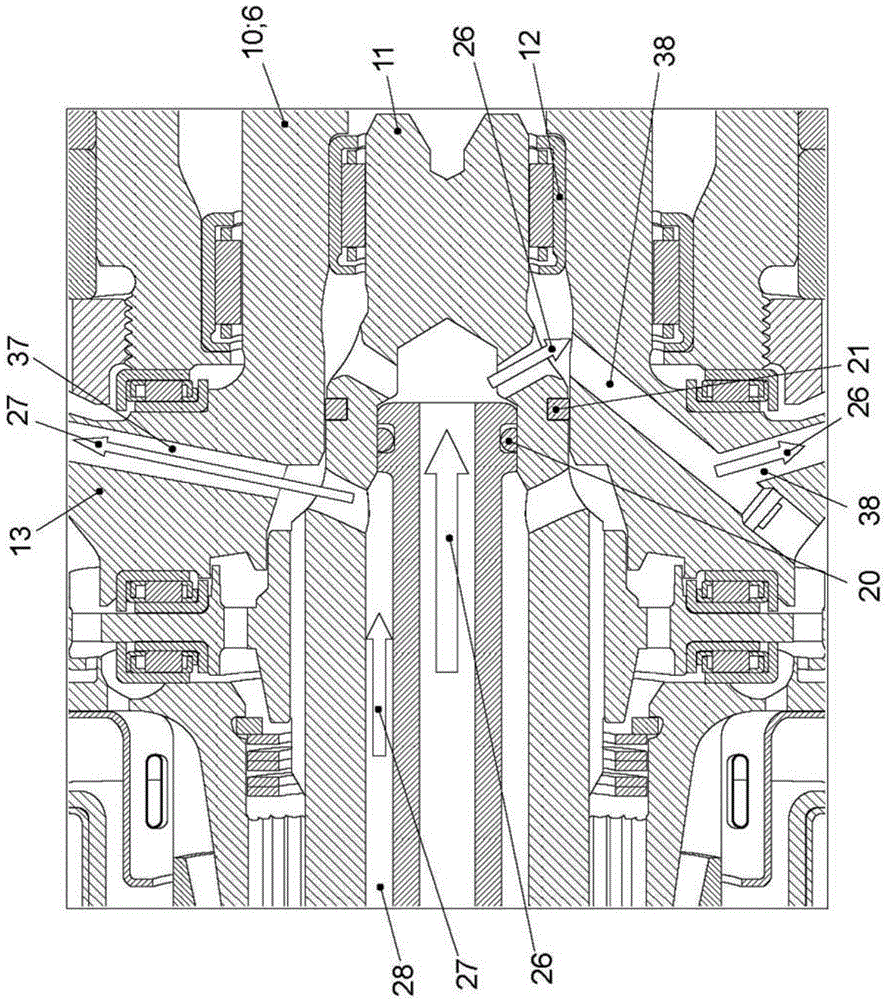

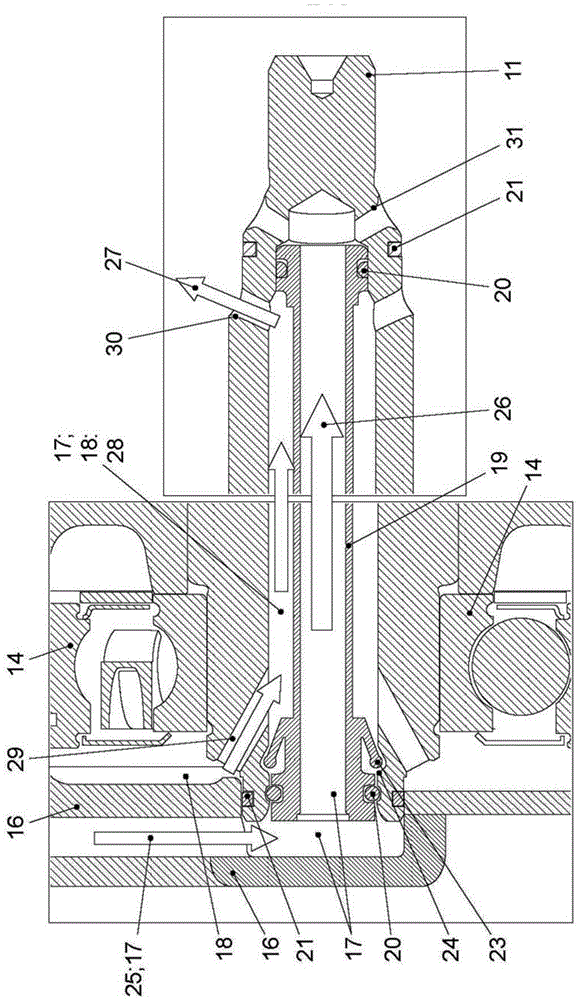

[0013] exist figure 1 The hybrid drive 1 with the dual clutch transmission 2 is clearly visible in the figure. The dual-clutch transmission 2 and the hybrid drive 1 are part of a drive train (not shown in detail) of a motor vehicle (not shown in detail). The hybrid drive 1 has an electric machine 3 . The electric motor 3 is designed as a rotary piston and has a rotatable rotor 4 and a stator 5 fastened to the housing. The electric machine 3 can work as a generator or as an electric motor.

[0014] Furthermore, the hybrid drive 1 has a drive shaft 6 . The drive shaft 6 can be driven by a (not shown) internal combustion engine. Drive shaft 6 is connected with double inertia flywheel 7. The drive shaft 6 can be functionally coupled to the rotor 4 . The drive shaft 6 can be coupled or decoupled by means of the separating clutch K0. As a result, the internal combustion engine can be coupled or decoupled by means of the separating clutch K0. The refinement is preferably desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com