Pneumatic assembling tool for compression springs

A technology for assembling tooling and compression springs, which is applied in the field of compression spring pneumatic assembly tooling and tooling for assembling compression springs, can solve the problems of inapplicability to large-scale assembly production, poor safety performance, time-consuming and labor-intensive problems, and achieve convenient assembly and maintenance. Ease of operation and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

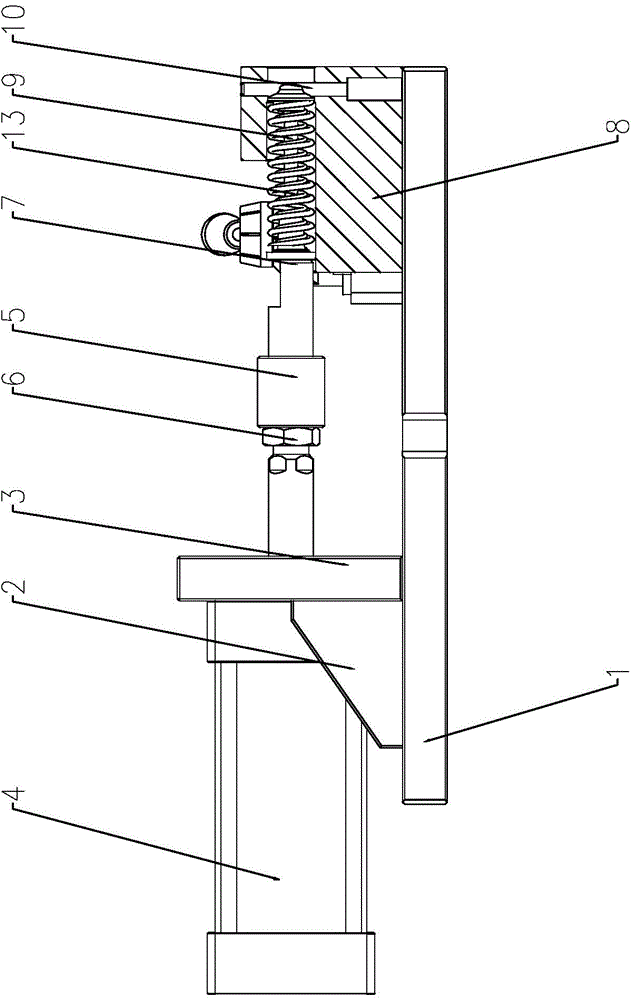

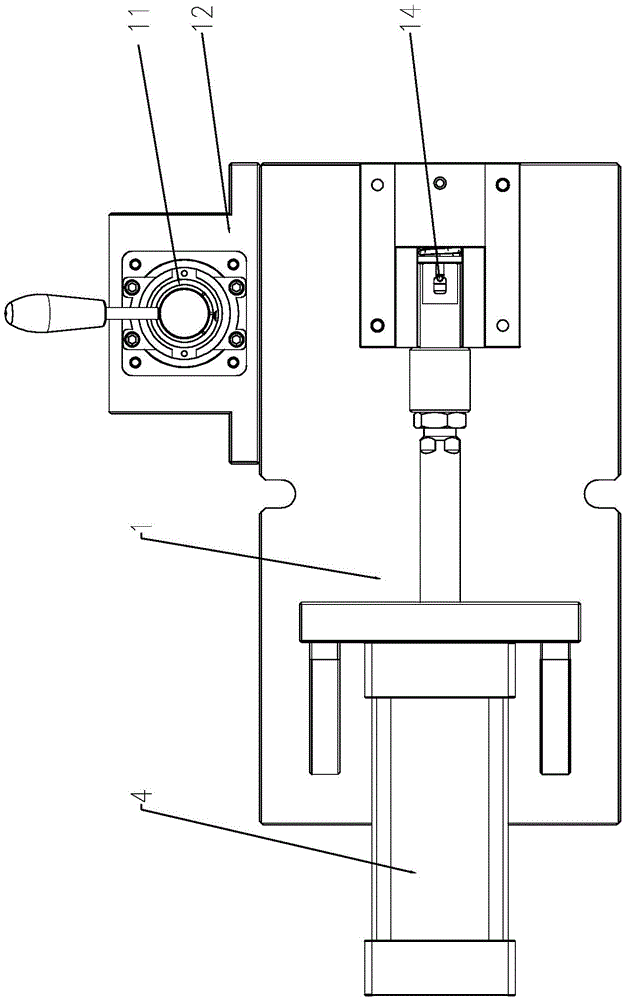

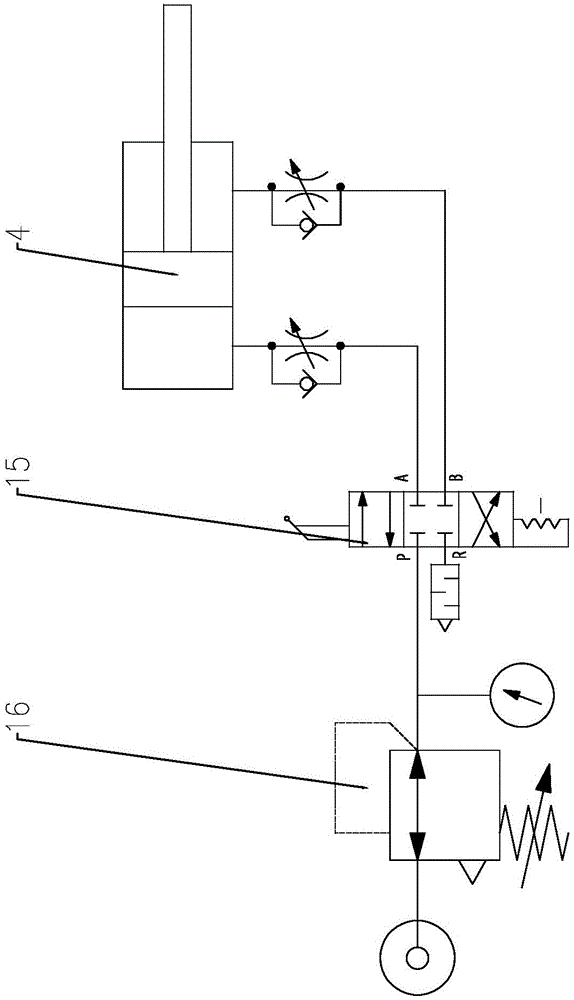

[0014] Such as Figure 1~2 As shown, the present invention mainly includes a bottom plate 1 on which a mounting plate 3 and a mounting base 8 are fixed in sequence. Cylinder 4 is fixed on the mounting plate 3, and the piston rod front end of cylinder 4 is connected with depression rod 5, and depression rod 5 locks the position by nut 6 on the piston rod of cylinder 4.

[0015] A spring mounting hole is horizontally arranged on the mounting base 8 , and the rear part of the spring mounting hole passes through the positioning pin 10 vertically. Guide rod 9 is installed in the spring mounting hole, and spring 13 is set on the guide rod 9, and the front end of spring 13 is provided with guide sleeve 7, and the groove positioning on the locating pin 10 is positioned at the rear end of spring 13. The guide rod 9 is provided with a pin hole, and when the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com