Novel automatic cleaning machine for inside and outside of water barrel

A cleaning machine and bucket technology, which is applied to cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of slow speed, secondary pollution of the environment, and cleaning without buckets, so as to reduce production costs and improve sanitation Quality and the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

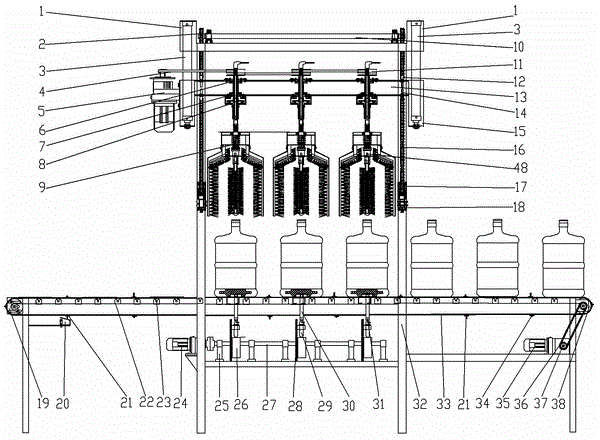

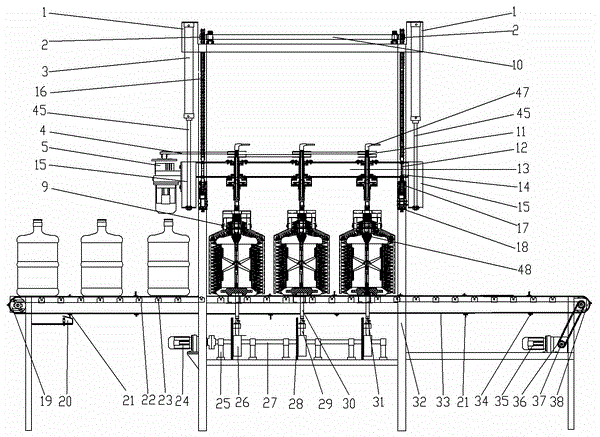

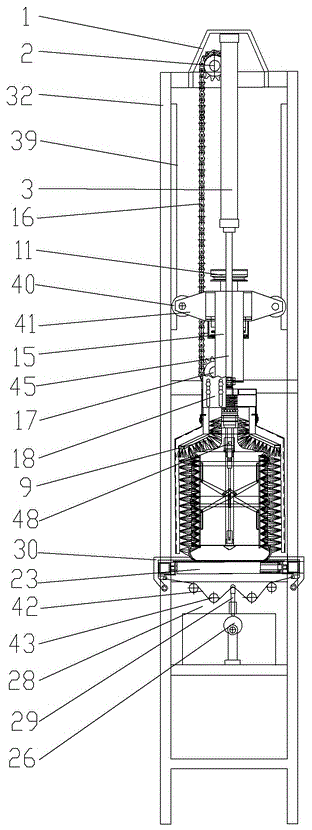

[0010] The new type of automatic bucket cleaning machine is mainly composed of cylinders, conveyor belts, inner brushes, outer brushes, etc. After the air cylinder (3) enters the air, the cylinder shaft (45) pushes down and is connected with the bucket brush sliding frame (13). While the lower seat of the cylinder (15) slides downward, the barrel motor (24) drives the eccentric wheel (26) on the eccentric wheel shaft (27) to rotate, and the push and pull shaft (29) slides upward to pull the pull wire (42) And pull the frame bucket tongs (30) pinned on the frame (32) by the clamped bucket tongs positioning pin (31) to rotate towards the water bucket, so that the bucket clips are tightly clamped on both sides of the bottom of the bucket, see image 3 , at this time, the inner and outer bucket brushes (9) slide to the cleaning position, and the brushes in each part of the bucket expand to the cleaning position, and are rotated and cleaned under the drive of the cleaning motor, see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com