Hot-air ageing test box for rubber

A technology of hot air aging and test chamber, which is applied in the preparation of test samples, weather resistance/light resistance/corrosion resistance, measuring devices, etc. It can solve the problems that the aging test chamber is difficult to achieve, and achieve the effect of uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

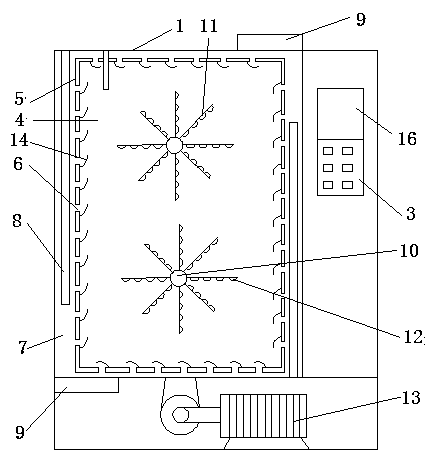

[0019] like Figure 1-2 The shown rubber hot air aging test box includes a box body 1, a box door 2, and a controller 3 positioned at one side of the box body 1, and is characterized in that the box body 1 includes a test box 4, and the test box 4 is outsourced with Insulation layer 5, said test chamber 4 and insulation layer 5 are provided with intercommunicating ventilation hole 6; Between insulation layer 5 and box body 1 is hot-air passage 7, is positioned at insulation layer 5 both sides respectively in described hot-air passage 7 There is a heating pipe 8, and a blower fan 9 is provided at the end opposite to the heating pipe 8; two rotating shafts 10 are arranged at the central axis of the test chamber 4, and a group of rubber clamping plates 11 are uniformly arranged around the periphery of each rotating shaft 10, The rubber clamping plate 11 is provided with a clamping portion 12 , the distance between adjacent clamping portions 12 is 10 mm, and the rotating shaft 10 ...

Embodiment 2

[0021] The difference between embodiment 2 and embodiment 1 is that the distance between adjacent clamping parts 12 is 40 cm, and the clamping parts 12 are welded on the rubber clamping plate 11 ; the door 2 is provided with an observation window 15 .

Embodiment 3

[0023] The difference between embodiment 3 and embodiment 2 is that the distance between adjacent clamping parts 12 is 20 mm, and the aging test chamber is also provided with a liquid crystal display 16 for displaying information such as test parameters; the chamber door 2 is provided with a handle 17 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com