Method for testing continuous distribution of crystal density based on density gradient light transmittance method

A technology of density gradient and crystal density, which is applied in the direction of measuring devices, specific gravity measurement, and analysis of materials, can solve the problems of low accuracy, inability to describe the distribution of particle density, and inability to accurately draw the continuous distribution curve of particle density, so as to achieve simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Sample type to be tested: HMX explosive crystal sample

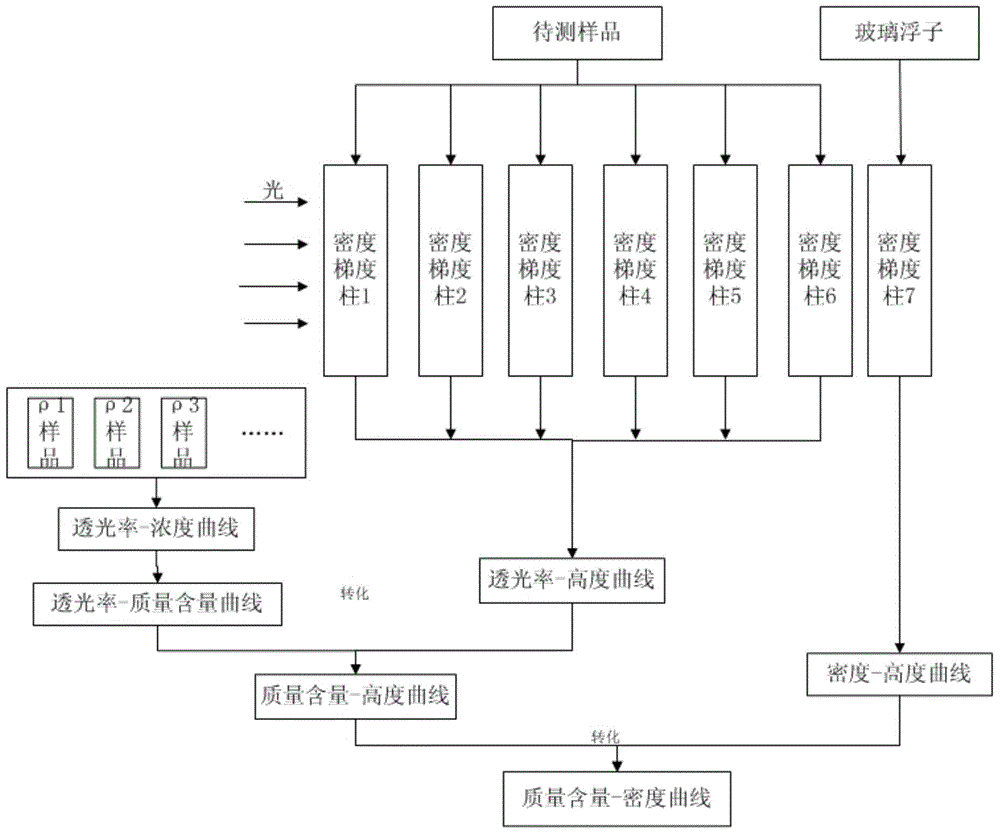

[0037] (1) Configure different concentrations of HMX explosive samples, measure the absorbance of visible light, obtain the calibration curve of light transmittance and explosive sample concentration, and then convert the light transmittance-concentration curve into light transmittance-mass according to the volume of the crystal sample Content curve; this step can only be carried out for the first time, and the light transmittance-concentration curve of the corresponding explosive sample is selected in the later experimental process for direct use. The light transmittance-mass content curves of some explosive crystal samples are available and can be directly used for reference without further determination.

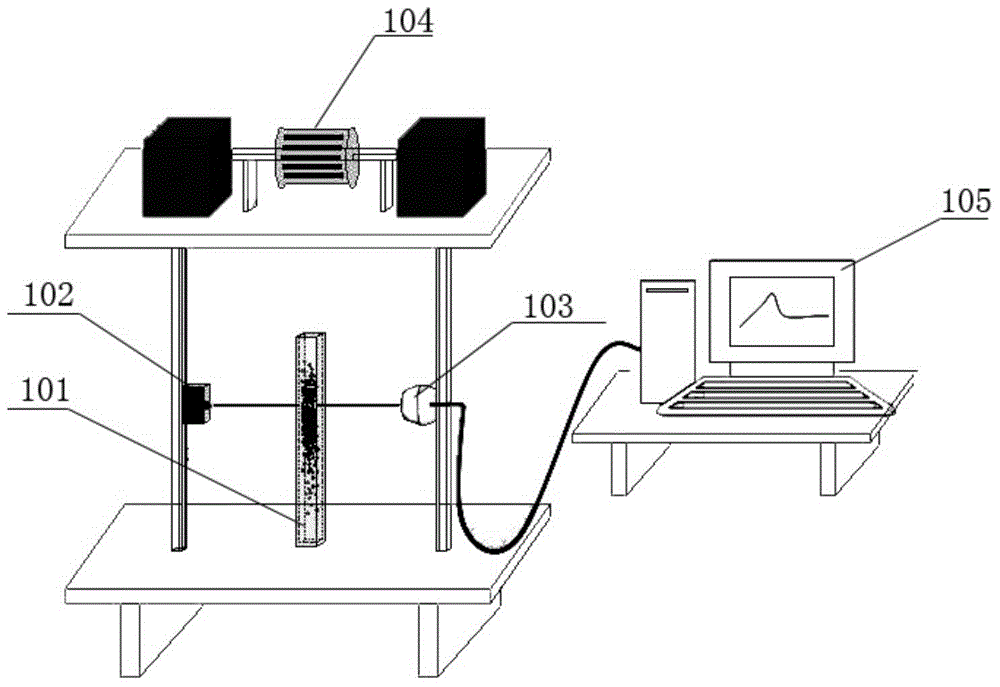

[0038] (2) Prepare a density gradient column array (a total of 7 columns) that can measure the density of multiple HMX explosive samples at the same time. The density gradient arrays are connected to each oth...

Embodiment 2

[0047] Sample type to be tested: RDX explosive crystal sample

[0048] (1) Configure different concentrations of RDX explosive samples, measure the absorbance of visible light, obtain the calibration curve of light transmittance and explosive sample concentration, and then convert the light transmittance-concentration curve into light transmittance-mass according to the volume of the crystal sample Content curve; this step can only be carried out for the first time, and the light transmittance-concentration curve of the corresponding explosive sample is selected in the later experimental process for direct use.

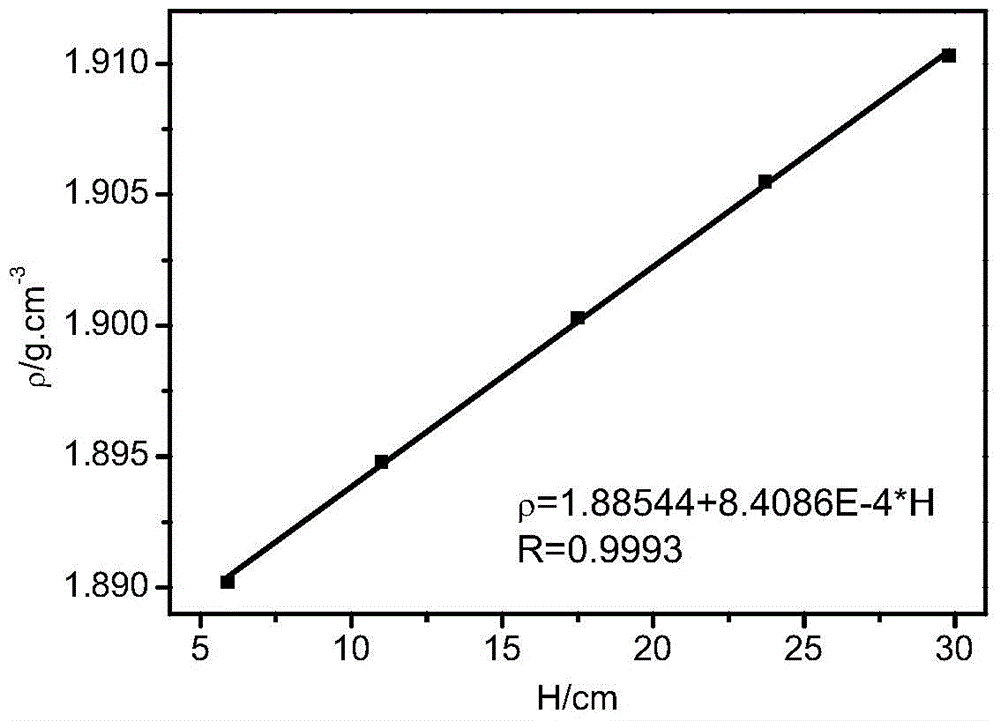

[0049] (2) Prepare a single density gradient column with continuous density distribution. The overall density liquid in the density gradient column is evenly distributed in the upper light and lower heavy, and the density range covers 1.885 ~ 1.915g / cm 3 .

[0050] (3) Use an electronic balance to weigh the RDX explosive crystal sample to be tested, soak it with ligh...

Embodiment 3

[0056] Sample type to be tested: CL-20 explosive crystal sample

[0057] (1) Configure CL-20 explosive crystal samples with different concentrations, measure the absorbance of visible light, obtain the calibration curve of light transmittance and explosive sample concentration, and then convert the light transmittance-concentration curve into light transmittance according to the volume of the crystal sample rate-mass content curve; this step can only be carried out for the first time, and the light transmittance-concentration curve of the corresponding explosive sample is selected in the later experimental process for direct use.

[0058] (2) Prepare a density gradient column array for the determination of the continuous density distribution of CL-20 explosive samples, which can simultaneously measure the density continuous distribution of 12 CL-20 samples. The density gradient arrays are connected to each other, and the liquid density at the same position in each column is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com