An Improved Stop Valve

A globe valve and valve body technology, applied in the field of globe valves, can solve the problems of valve corrosion, reduced service life, valve damage, etc., and achieve the effect of increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

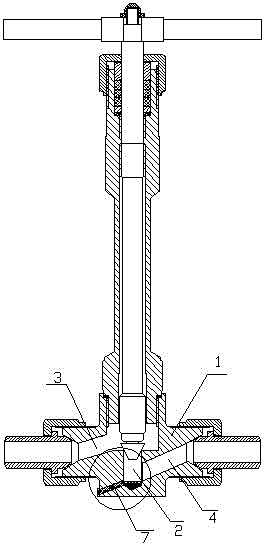

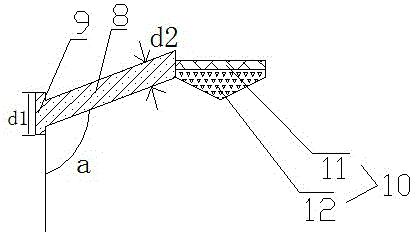

[0015] As shown in the figure, an improved shut-off valve includes a valve body 1, a transition chamber 2 is provided on the valve body 1, an inlet channel 3 and an outlet channel 4 are respectively provided on both sides of the transition chamber 2, and the transition chamber 2. The inlet channel 3 communicates with the outlet channel 4. A layer of filter membrane 5 is provided on the inside of the outlet channel 4. A drainage channel 6 is provided at the bottom of the transition chamber 2. The drainage channel 6 is a cylindrical structure. The drainage channel 6 is parallel to the outlet channel 4 and is arranged opposite to the outlet channel 4. The drainage channel 6 is provided with a fixed plug 7, and the fixed plug 7 includes a fixed plug body 8, a fixed plug end cover 9 and a filter member 10 , the fixed plug main body 8 is a cylindrical structure, the fixed plug main body 8 is interference fit with the drainage channel 6, the fixed plug end cap 9 is a cylindrical struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com