Efficient oil well pump for horizontal well

A technology for oil well pumps and horizontal wells, applied in the field of high-efficiency oil well pumps for horizontal wells, can solve problems such as large leakage, low pump efficiency, and short service life, and achieve the effects of improving pump efficiency, increasing suction coefficient, and ensuring clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

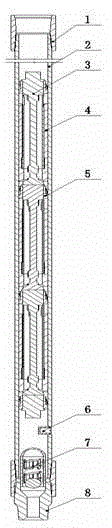

[0019] In order to further disclose the technical solution of the present invention, the structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

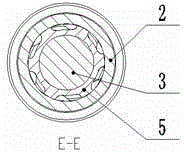

[0020] The invention includes an upper joint 1, a pump barrel 2, a plunger center rod 3, a plunger 4, a center rod centralizer 5, a pin drainer 6, a fixed valve assembly 7 and a joint type ball seat 8, and is characterized in that the plunger It is set as two-stage, three-stage or four-stage hollow plunger, with a floating valve arc seat on the lower end of each stage of plunger, and a plunger center rod at the center of each stage of plunger. There is a central rod centralizer at the upper end of the center rod of each plunger, and a traveling valve arc-shaped spool at the lower end. The sealing fit of the arc-shaped seat of the valve constitutes the forced opening and closing mechanism of the floating valve. Insert it into the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com