System for generating electric power by recovering waste heat of materials at top of fractionating tower

A fractionation tower and material technology, applied in the field of structural design of power generation systems, can solve problems such as energy waste, and achieve the effects of improving utilization efficiency, saving energy, and reducing use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

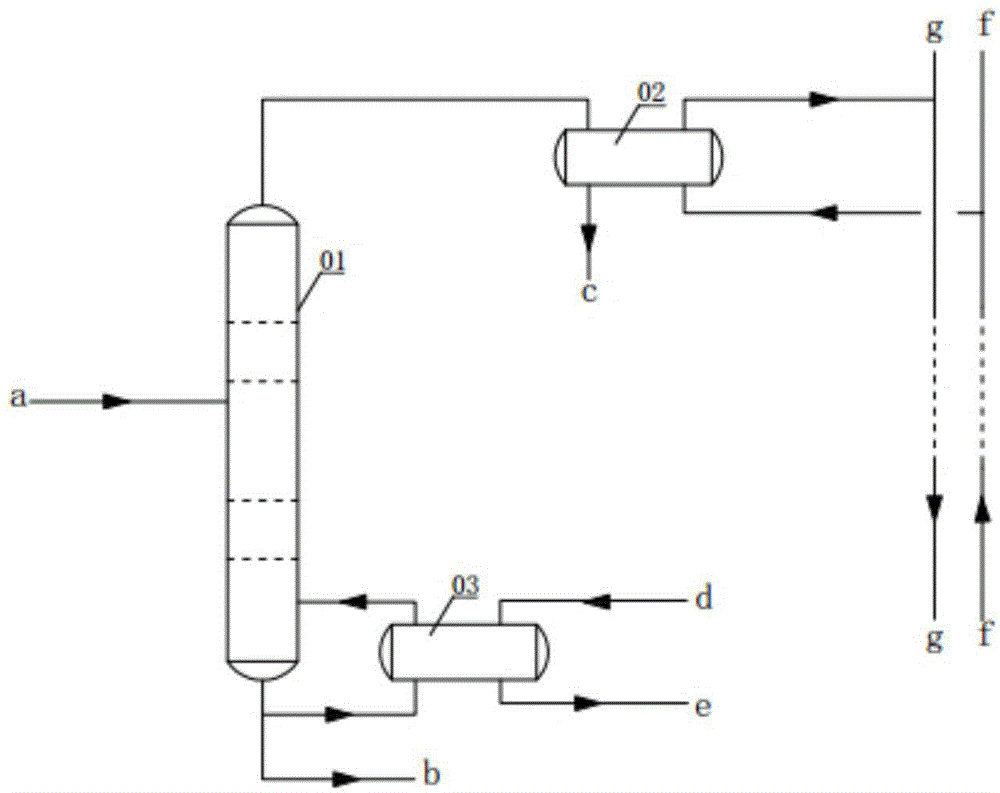

[0010] A system proposed by the present invention for recovering the waste heat of the top material of the fractionation tower for power generation is as follows in conjunction with the accompanying drawings and detailed description:

[0011] The structure of an embodiment of a system for recovering waste heat from the top material of a fractionation tower for power generation proposed by the present invention is as follows figure 2 As shown, the system mainly includes a fractionation tower 1, an organic working medium evaporator 2, a tower top cooler 3, a tower bottom material heater 4, a turbine 5, a reducer 6, a generator 7, a condenser 8, a working Quality well 9, working fluid pump 10. Its connection relationship is: the inlet 11 of the fractionation tower 1 is connected with the normal temperature material pipeline a, the outlet 12 of the fractionation tower 1 is connected with the material inlet 21 of the organic working medium evaporator 2, and the material outlet 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com