Coaxial all-metal cam stator and rotor underground dynamical drilling tool

A dynamic drilling tool and all-metal technology, which is applied to the driving device for drilling in the wellbore, drilling equipment, earthwork drilling and production, etc., can solve the problems of poor dimensional stability, low temperature resistance, low pressure bearing capacity of the screw stator, etc., to achieve Improve the service life, avoid high temperature resistance, and avoid uneven swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

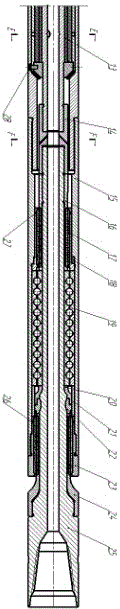

[0028] see Figure 1(a) , (b), a coaxial all-metal cam stator-rotor downhole motor, including a transition joint 1, the transition joint 1 is connected to a motor assembly through threads, and the motor assembly is connected to a drive shaft assembly through threads.

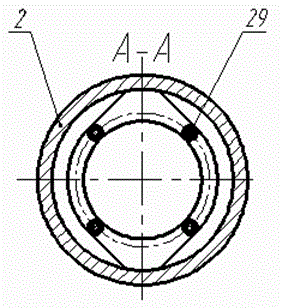

[0029] The motor assembly includes an upper motor base housing 2 and a lower motor base housing 10, a stator 5, an upper rotor 6 and a lower rotor 12 are arranged in the upper motor base housing 2 and the lower motor base housing 10, and the stator 5 is located outside the upper rotor 6 and the lower rotor 12, the upper end of the upper rotor 6 and the stator 5 is provided with an upper end cover 3, and the lower end of the stator 5 is provided with a support end cover 8, between the support end cover 8 and the upper motor base housing 2 A seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com