Yarn sizing device capable of recycling steam

A yarn and steam technology, applied in the field of textile equipment, can solve problems such as low utilization of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

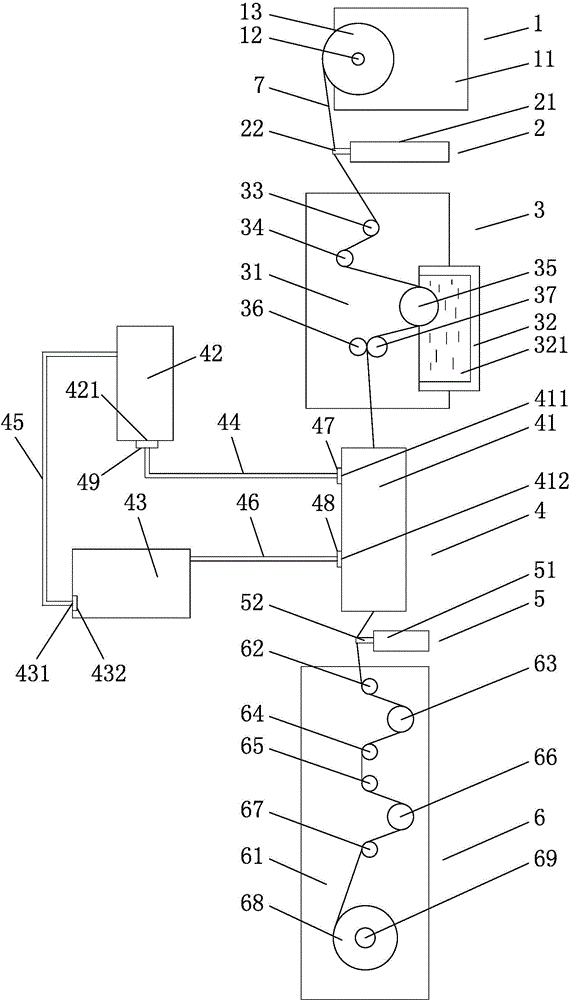

[0019] refer to figure 1 , a yarn sizing device that can recover steam, including a discharging device 1, a first yarn dividing device 2, a sizing device 3, a drying device 4, a second yarn dividing device 5 and a yarn receiving device 6 arranged in sequence. Drying device 4 comprises steam oven 41, steam boiler 42 and liquid recovery pond 43, and steam oven 41 is communicated with liquid recovery pond 43 by first steam pipe 46, and liquid recovery pond 43 is communicated with steam boiler 42 by second steam pipe 45, The steam boiler 42 communicates with the steam oven 41 through a third steam pipe 44 . The steam outlet 421 of the steam boiler 42 is provided with a pressure reducing valve 49 , and the steam boiler 42 communicates with the third steam pipe 44 through the pressure reducing valve 49 . The water in the steam oven 41 that flows into the liquid recovery pool 43 when it is cold can be reused by the steam oven 41, effectively avoiding the waste of water resources.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com