Environment-friendly closed building exterior wall paint and preparation method thereof

An environmentally friendly technology for building exterior walls, applied in the field of building exterior wall coatings and coatings, can solve the problems of poor water resistance, alkali resistance, and inability to effectively prevent the topcoat from blooming, whitening, and discoloration, and achieve super-long water resistance , Increase acid and alkali resistance and electrical insulation performance, excellent adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

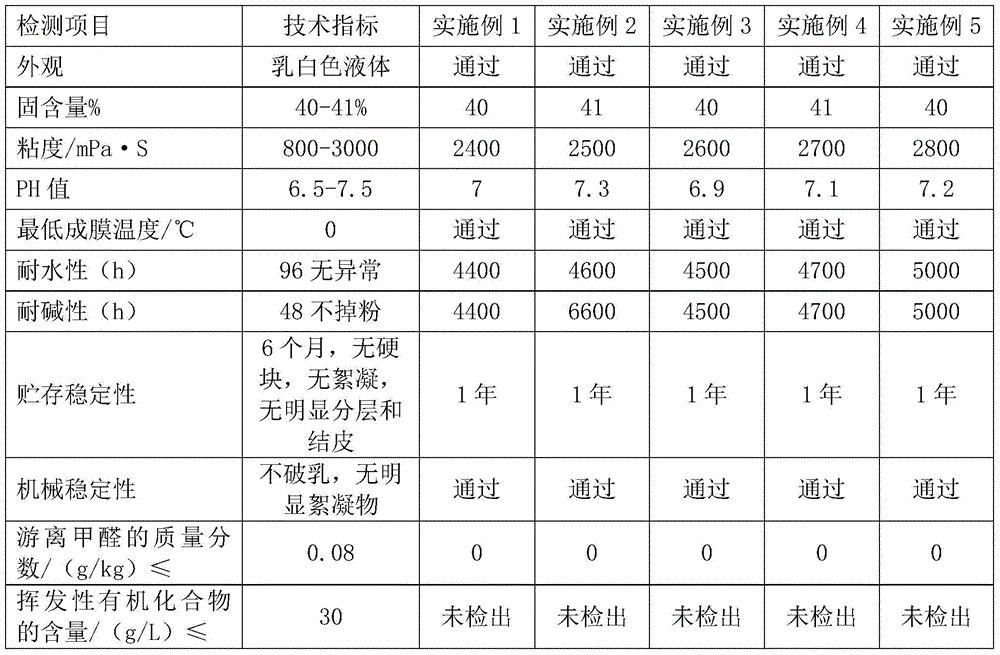

Examples

Embodiment Construction

[0011] Below in conjunction with specific embodiment, technical solution of the present invention is described in further detail:

[0012] One, the source of each component of the present invention:

[0013] Water (local), ZS-6501 back cover emulsion (industrial grade product of Jiangsu Zishi Chemical Technology Co., Ltd.), A-90 anti-alkali back cover emulsion (industrial grade product of Shanghai Zhenzhou Chemical Coating Co., Ltd.), high-efficiency coalescent JS- PPH (302) (industrial grade product of Shanghai Jinshan Chemical Co., Ltd.), superfine mica powder (industrial grade product of Lingshou County Mica Chemical Co., Ltd., Shijiazhuang, Hebei), anti-mold preservative SPM (industrial grade product of Guangzhou Zhuozhou Trading Co., Ltd. ), GHP-102 thickener ( Shenzhen Yoshida Chemical limited company Industrial grade product), silicone defoamer JS-2010S (industrial grade product of Shanghai Jinshan Chemical Co., Ltd.).

[0014] Two, by mass percentage content embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com