A Reverse Bending Tempered Glass Forming Device and Operation Method

A glass forming and operating method technology, applied in glass forming, glass remolding, glass tempering and other directions, can solve the problems of damage to the ceramic roller table in the heating furnace, inability to process the curved tempered glass, damage to the screen printing ink, etc. Improve product quality and quality, high efficiency in glass production, convenient and fast use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

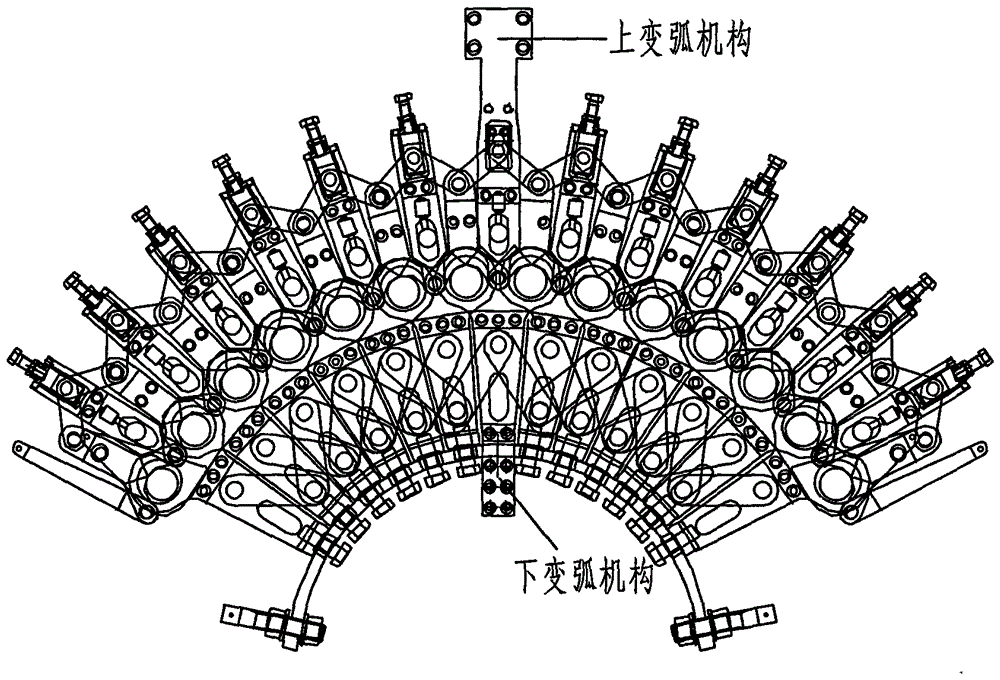

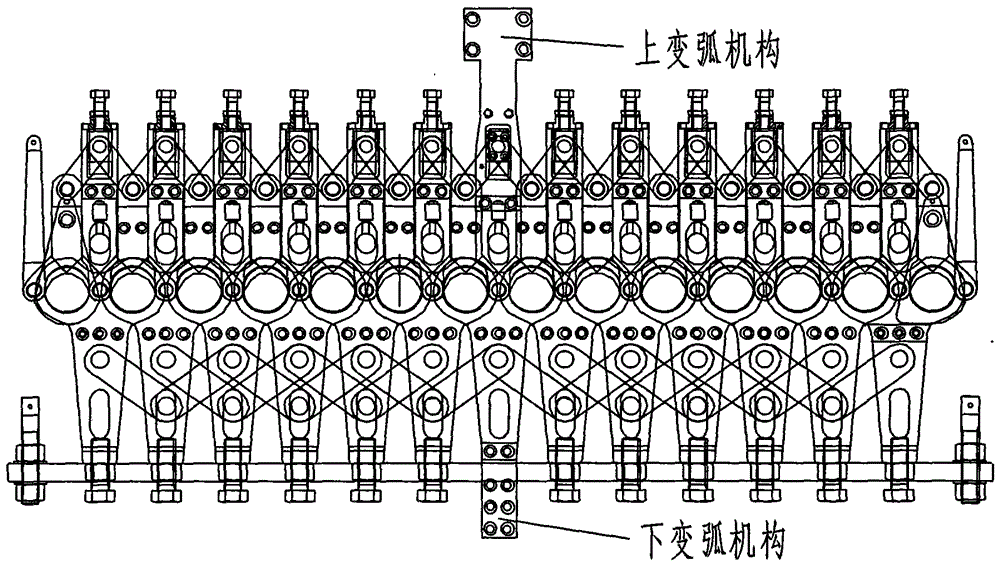

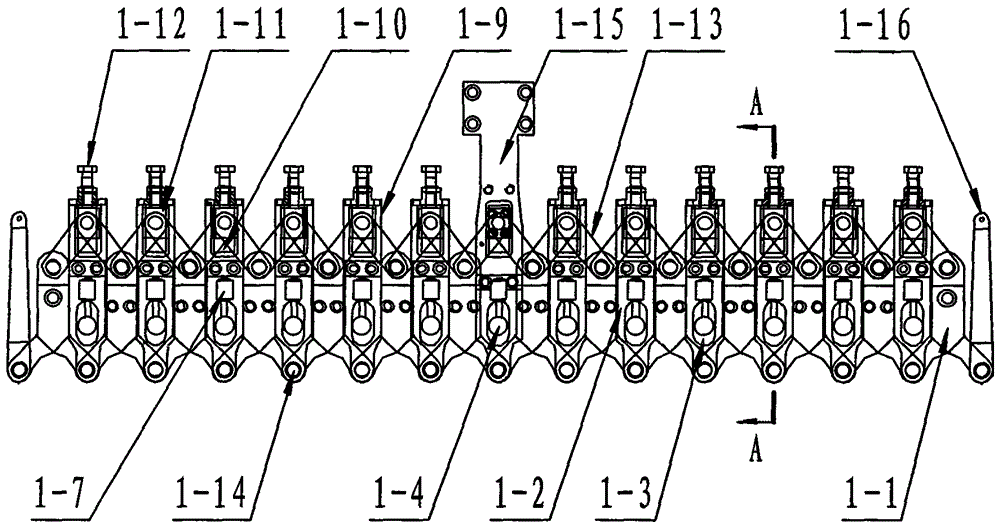

[0027] At least one set of inverted Y-shaped arc connecting plates 1-1 is correspondingly connected and arranged. An upper arc connecting plate 1-2 is set between two adjacent inverted Y-shaped arc connecting plates 1-1, and an arc is set above the upper arc connecting plate 1-2. Adjusting sliding seat 1-9, two V-shaped upper arc adjusting connecting rods 1-13 are set between two adjacent arc adjusting sliding seats 1-9 to form an upper arc changing mechanism; the upper sides of the inverted triangle connecting plate 2-1 Set the roller path hole 2-2, the roller path holes 2-2 of the two adjacent inverted triangle connecting plates 2-1 are arranged correspondingly, and the roller path hole 2-2 is set in the roller path hole 2-2, and the two adjacent ones are inverted triangle connecting plates. Two X-shaped lower arc adjustment links 2-6 are set between 2-1, bracket 2-9 is set under the inverted triangle connecting plate 2-1, and two ends of bracket 2-9 are set up with lifting ro...

Embodiment 2

[0029] The two holes below the inverted Y-shaped arc connecting plate 1-1 of the upper arc changing mechanism and the holes at the lower end of the upper arc connecting plate 1-2 are correspondingly provided with pins 1-14, and the middle part of the upper arc connecting plate 1-2 is provided Press roller lifting holes 1-3, press roller lifting holes 1-3 are provided with press rollers 1-4, one end of press roller 1-4 is provided with T-shaped connecting plate 1-5, and the upper part of T-shaped connecting plate 1-5 corresponds to The arc coupling plate 1-2 is provided with a positioning plate 1-6, one side of the positioning plate 1-6 is provided with a cylinder 1-7, and the central hole of the positioning plate 1-6 is provided with an adjusting rod 1-8, the piston rod of the cylinder 1-7 and The lower part of the adjusting rod 1-8 is set corresponding to the two ends of the T-shaped connecting plate 1-5, and the upper end of the adjusting rod 1-8 is provided with bolts; the up...

Embodiment 3

[0031] At least four fixing holes are arranged above the lifting fixing frame 1-15; each group of inverted Y-shaped arc connecting plates 1-1 has at least six.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com