Rapid molding method of pre-stressed tubular member

A technology of tubular components and forming methods, which is applied in the field of preparation of tubular components, can solve the problems of large volume of tubular components, small number of effective loads, complicated installation, etc., achieve good mechanical properties and physical and chemical properties, save space and total amount, and form The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

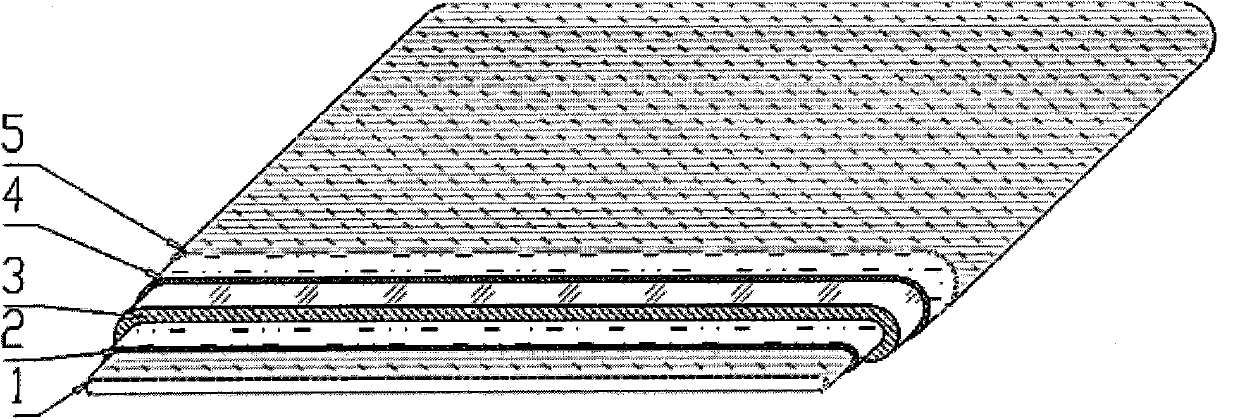

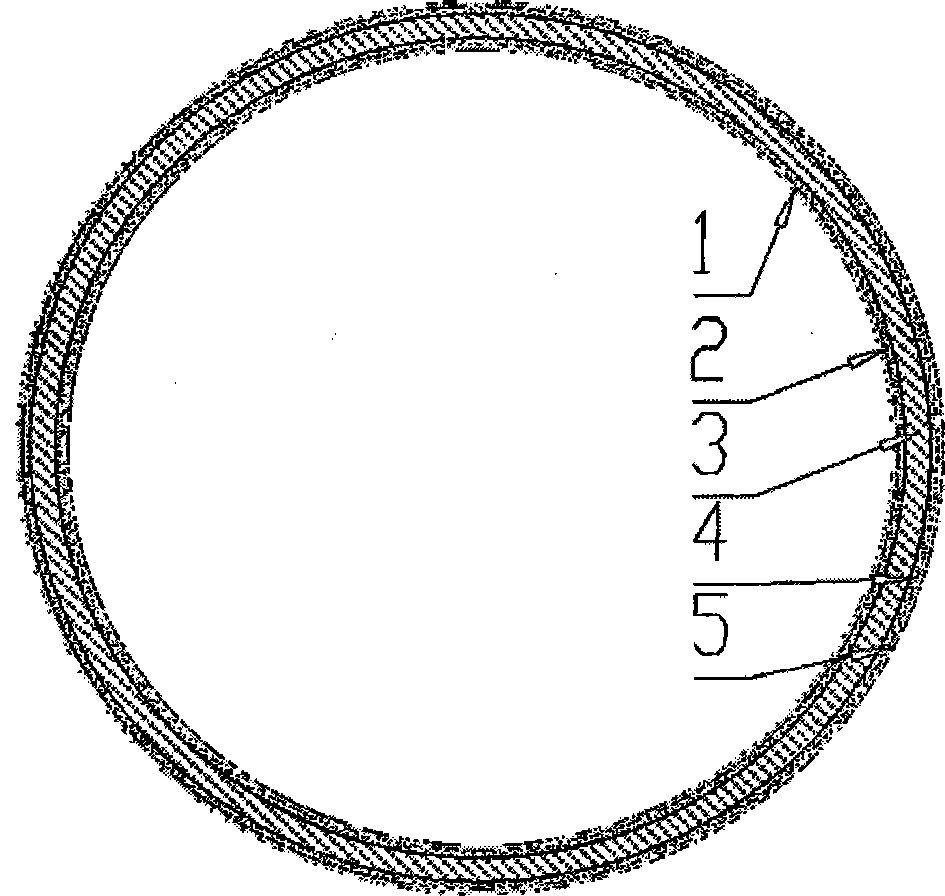

[0021] Such as figure 1 and figure 2 As shown, the prestressed tubular member in the present invention includes an annular composite material layer 3, the inner surface of the composite material layer 3 is provided with an inner process function auxiliary layer 2, and the inner surface of the inner process function auxiliary layer 2 is provided with an inner seal Layer 1; the outer surface of the composite material layer 3 is provided with an outer technical function auxiliary layer 4, and the outer surface of the outer technical function auxiliary layer 4 is provided with an outer sealing layer 5.

[0022] A kind of rapid prototyping method of tubular member with prestress of the present invention, comprises the following steps:

[0023] (1) After transporting the pre-rolled rapid-forming tubular member to the site, the product is cut according to the length required, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com