Squeeze casting equipment based on power ultrasonic and pressure coupling

A technology of squeeze casting and high power, which is applied in the field of metal material processing, can solve the problems of single physical field effect of metal melt, inability to carry out quantitative analysis, complex ultrasonic attenuation law, etc., to achieve improved structure and performance, simple structure and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this embodiment, a squeeze casting method based on power ultrasonic and pressure coupling includes the following steps:

[0041] (1) Preheat the mold cavity of the extrusion casting equipment until the temperature of the inner surface of the mold cavity wall reaches 250°C; the material of the mold cavity is H13 steel, lubricated with graphite oil;

[0042] (2) After heating the metal melt to the preset temperature, pour it into the mold cavity, and turn on the heat preservation heater at the same time to keep the mold cavity warm (the heat preservation time is the whole process of the synergistic coupling of power ultrasonic and pressure until Until the metal melt solidifies to form a metal solid, it can generally be 10s to 60s);

[0043] Among them, the preset temperature of the metal melt is in the temperature range of 10-100°C above the liquidus line; when the heat preservation heater heats the mold cavity, the temperature of the inner side of the mold cavity is k...

Embodiment 2

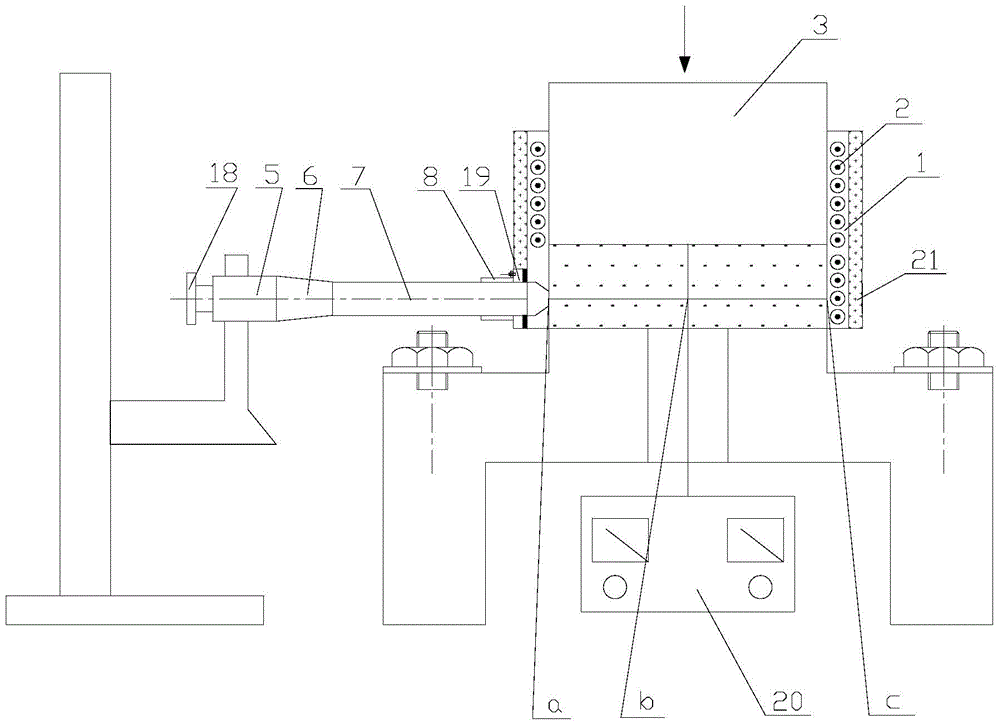

[0051] In this embodiment, a squeeze casting equipment based on power ultrasonic and pressure coupling for the method described in Embodiment 1, such as figure 1 As shown, including mold cavity 1, heat preservation heater 2, punch 3, power ultrasonic generator, mold cooling system and data collector 20, metal melt is placed in the mold cavity, and the cavity wall of the mold cavity is set There is a heat preservation heater, the punch is set above the mold cavity, the power ultrasonic generator passes through the cavity wall of the mold cavity, and is inserted into the metal melt from the side of the mold cavity, and the mold cavity is equipped with a mold cooling system. The data collector is connected with the outside of the cavity wall of the mold cavity.

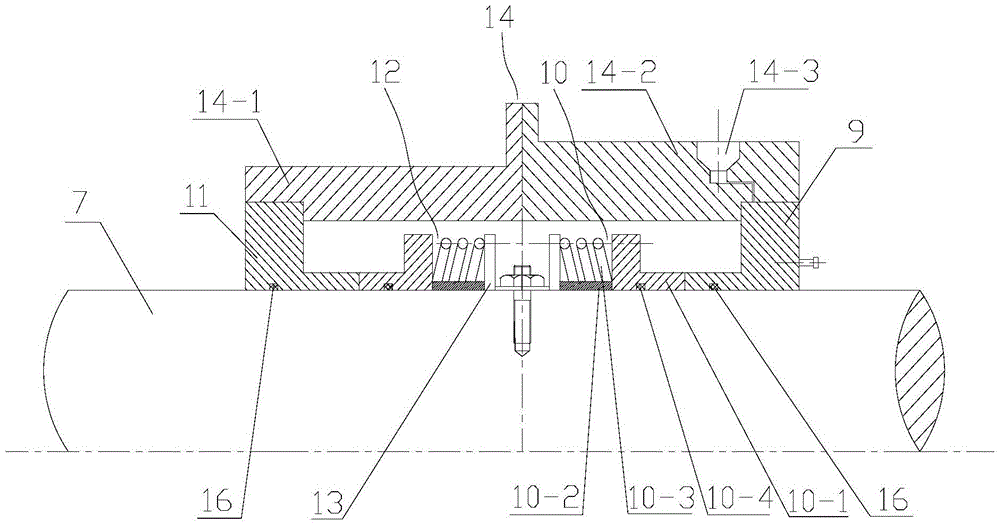

[0052] The power ultrasonic generator includes ultrasonic transducer 5, ultrasonic horn 6 and ultrasonic introduction rod 7 connected in sequence, the end of the ultrasonic introduction rod has a rod tip, and after the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com