Mining backwash filter

A backwashing and filter technology, applied in the field of filters, can solve the problems of affecting the filtering speed and filtering efficiency of filter elements, affecting normal production, long replacement time, etc., and achieve the effect of shortening cleaning time, fast cleaning and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

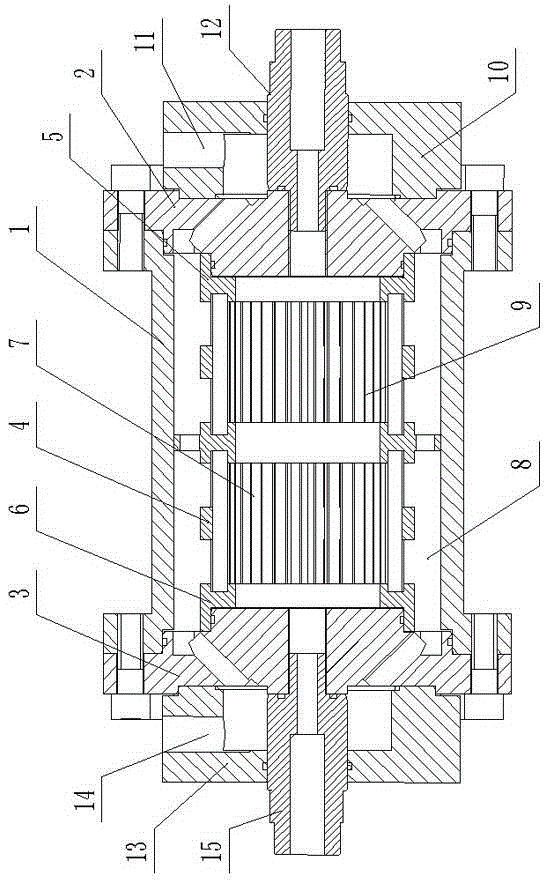

[0027] Such as Figure 1-5 As shown, the mining backwash filter includes an outer cylinder 1, one end of the outer cylinder 1 is sealed by the first end cover 2, and the other end is sealed by the second end cover 3, and the outer cylinder 1 is provided with a mesh cylinder 4, and the mesh cylinder One end of 4 is connected with the first end cover 2 through the first net tube end cover 5, and the other end is connected with the second end cover 3 through the second net tube end cover 6, and a filtering device 7 is arranged in the net tube 4 ;

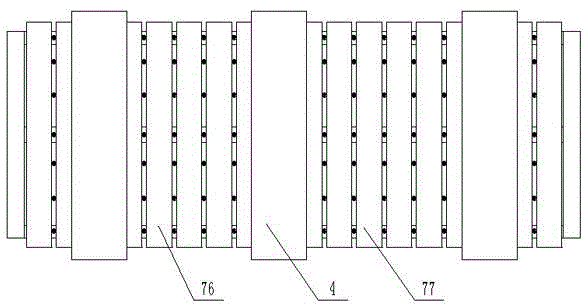

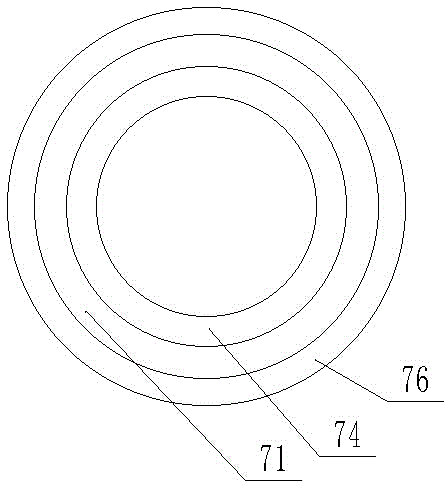

[0028] The filter device 7 is provided with a support frame 71, the support frame 71 includes two rings 72, the two rings 72 are connected by a plurality of cross bars 73 to form a cylindrical frame, the outer surface of the support frame 71 is wound with steel wire 77 forms filter screen 76, forms the gap that can pass through between the adjacent steel wire 77, and the inside of support frame 71 is provided with liner cylinder 74, h...

Embodiment 2

[0032] Such as Figure 1-6 As shown, the difference between this embodiment and Embodiment 1 is that a plurality of grooves 75 are arranged on the cross bar 73, and steel wires 77 are wound in the grooves 75 to form a filter screen 76, and the steel wires 77 are clamped in the grooves 75, without It will slide freely to ensure the filtering accuracy.

Embodiment 3

[0034] Such as Figure 1-6As shown, the difference between the present embodiment and the second embodiment is that the cross section of the groove 75 is an inverted triangle, the cross section of the steel wire 77 is a triangle matching the groove 75, and the edges of the steel wire 77 are clamped in the groove 75. Inside, adjacent steel wires 77 form a gap with a small top and a large bottom. When filtering, the filtrate flows from the small mouth of the gap to the big mouth. The filtering effect is good and it is not easy to block the filter screen 76. The large mouth of the gap flows to the small mouth, the backwashing pressure increases, the backwashing effect is good, and the time is short.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com