Self-walking type scattered reed conveying, bundling and cutting integrated machine

A self-propelled, all-in-one machine technology, applied in the direction of packaging, agricultural machinery and implements, applications, etc., can solve the problems of complex structure of the bundling device, increased manufacturing cost, low efficiency of manual reed bundling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

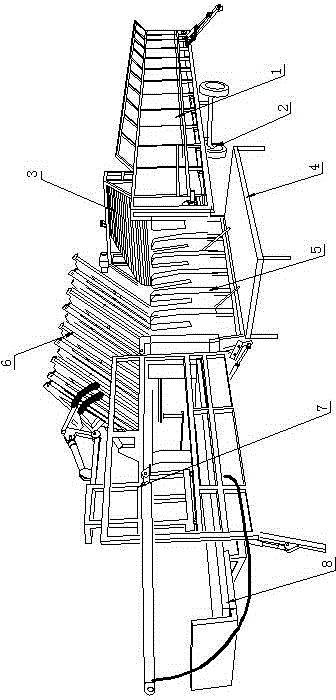

[0041] Embodiment 1: as figure 1 As shown, a loose reed conveying, bundling and cutting machine includes a conveyor 1, a bundling and cutting machine 5, a control room, a reed cutting platform 8, and a binding mechanism 7;

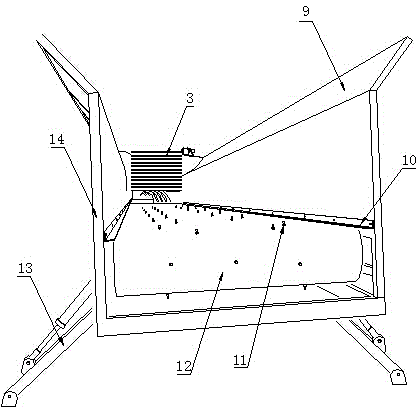

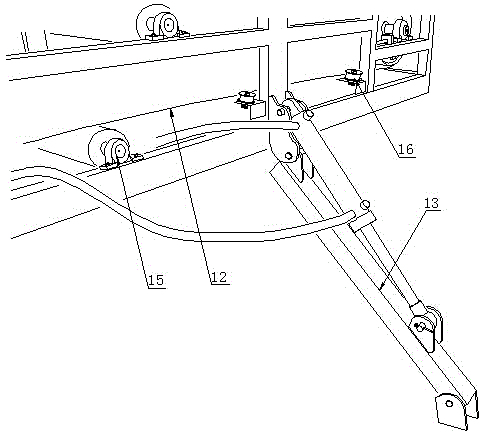

[0042] Conveyor: as Figure 1-5Shown, comprise frame 14, walking wheel 2, driving device and conveying device, conveying device comprises conveyer belt 12 and pressure reed rotating cage 3, has several hanging reed piles 11 arranged at intervals on the conveyer belt 12, is convenient to hang Loose reeds are transported forward, and the conveyor belt 12 is installed on the bottom of the frame 14 and forms a long groove with the top and both ends of the frame 14. The top opening 9 of the frame 14 is bell-shaped. An anti-pinch reed angle iron 10 is installed on the frame 14 in contact with the conveyor belt 12, idler rollers 15 are installed at intervals on the frame 14 below the conveyor belt 12, and idlers 15 are installed at intervals on the frame 14...

Embodiment 2

[0048] Embodiment 2: as Figure 10 As shown, the cutting knife body 37 is directly connected with the hydraulic cylinder 41, and the frame at the output end of the bundling table 30 is equipped with a knife rail 43 up and down, the cutting knife body 37 is embedded in the knife rail, and the upper and lower edges of the cutting knife body are also installed There is a clip blade 42 to enhance the strength of the cutter body 37 . All the other are identical with embodiment 1.

Embodiment 3

[0049] Embodiment 3: as Figure 14 As shown, in order to realize the self-propelling of the all-in-one machine, a differential 59 is installed on the axle 63 of the traveling wheel of the conveyor and / or the traveling wheel of the bundling and cutting machine, and the differential 59 passes through the universal joint 60, The transmission shaft 61 is connected to a speed reducer 62 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com