Bell-type furnace with a heat dispensing device positioned within a protective hood, in particular fed by an energy source external to the furnace chamber, for dispensing heat to annealing gas

A technology for annealing furnaces and protective covers, which can be used in bell-type furnaces, heat treatment furnaces, furnaces, etc., and can solve problems such as high energy consumption and heavy furnaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

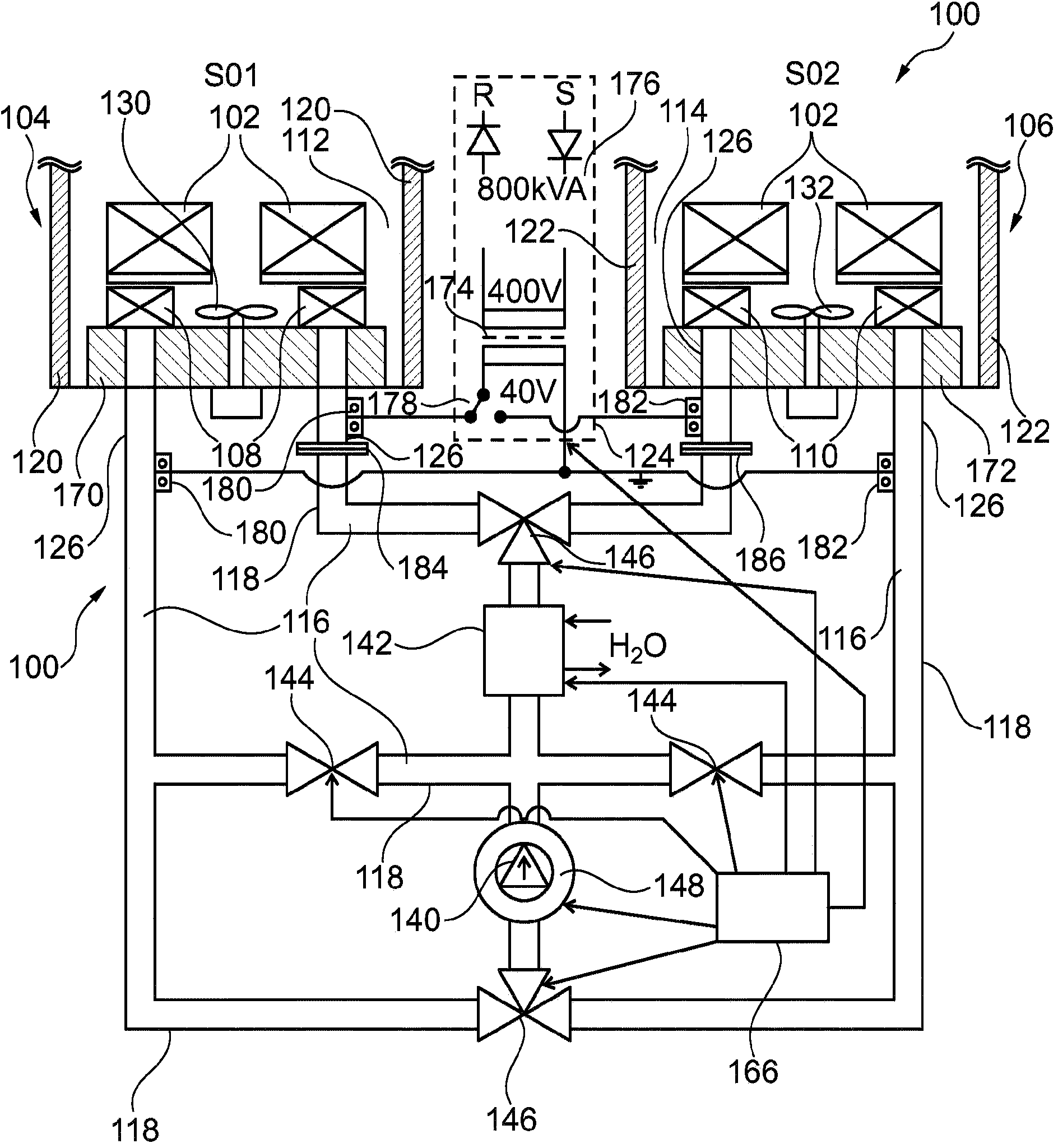

[0058] Below, refer to figure 1 Now, a bell furnace 100 according to an exemplary embodiment of the present invention will be introduced.

[0059] The bell furnace 100 is designed for the heat treatment of an annealing material 102 . The annealing material is arranged partly on the first bottom So1 of the bell furnace 100 and partly on the second bottom So2 of the bell furnace 100 . exist figure 1 The annealing material 102 , which is only schematically shown in , may for example be a coil of steel strip or wire rod or the like (for example a layered bulk material) which is to be subjected to heat treatment.

[0060] The bell furnace 100 has a first sealable furnace chamber 104 which is assigned to a first furnace bottom So1 . The first furnace chamber 104 is used for accommodating and heat-treating the annealing materials 102, and the annealing materials 102 are delivered to the first furnace bottom So1 in batches. For the heat treatment, the first furnace chamber 104 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com