Wind turbine

A technology for wind power generation equipment and generators, applied to wind power generator components, wind power generation, wind power engines, etc., which can solve problems such as planetary hole casting problems, and achieve the effect of avoiding rotation and/or axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0036] Aluminum-based bearing alloys, especially:

[0037] AlSn6CuNi, AlSn20Cu, AlSi4Cd, AlCd3CuNi, AlSi11Cu, AlSn6Cu, AlSn40, AlSn25CuMn, AlSi11CuMgNi;

[0038] Copper-based bearing alloys, especially:

[0039] CuSn10, CuAl10Fe5Ni5, CuZn31Si1, CuPb24Sn2, CuSn8Bi10;

[0040] Tin-based bearing alloys, especially:

[0041] SnSb8Cu4, SnSb12Cu6Pb.

[0042] Bearing alloys based on nickel alloys, silver alloys, iron alloys or chromium alloys other than the listed bearing alloys may also be used.

[0043] The bonding layer or the diffusion barrier layer can consist, for example, of an aluminum layer, a tin layer, a copper layer, a nickel layer, a silver layer or alloys thereof, in particular binary alloys.

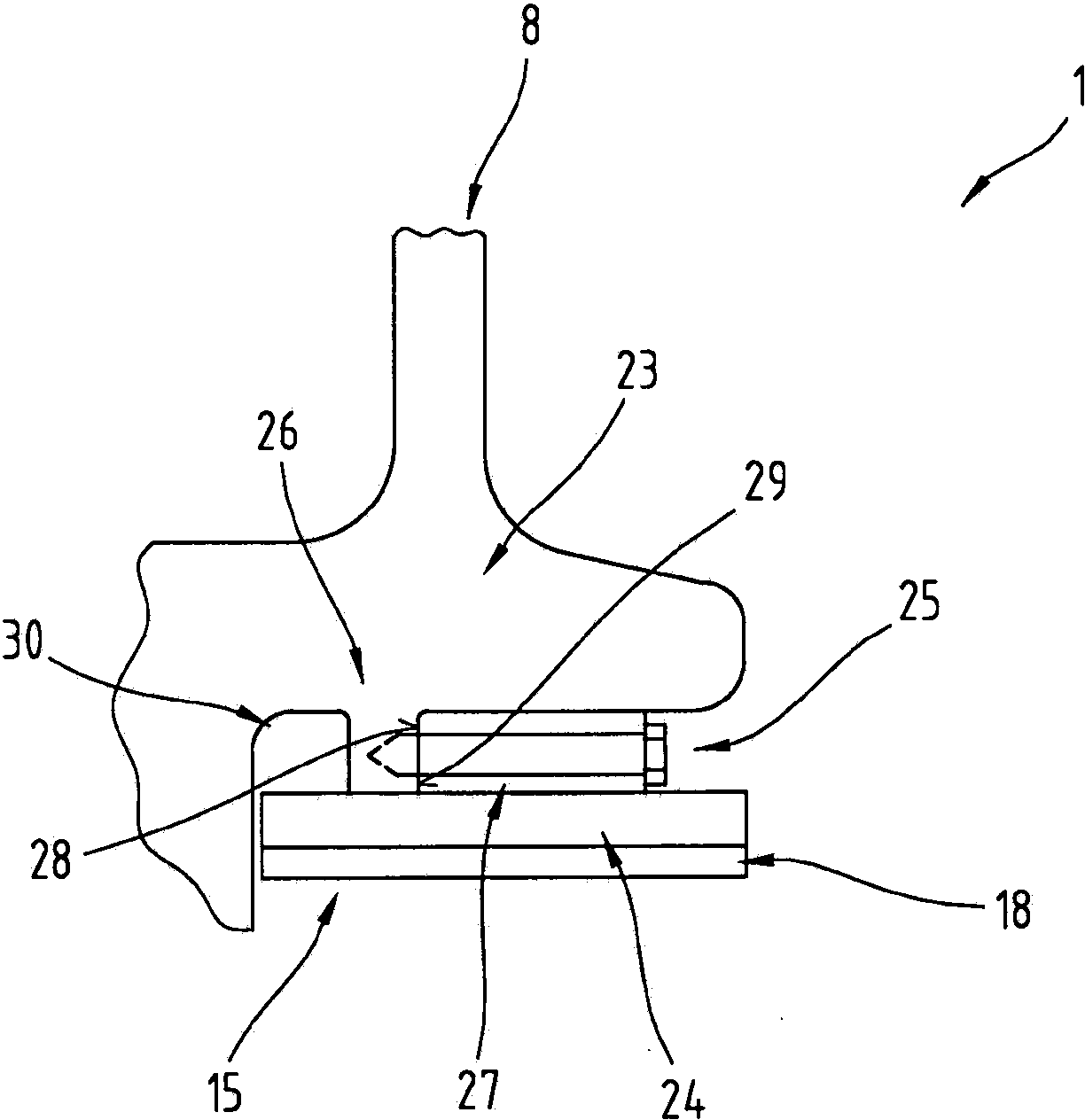

[0044] Preferably the support layer 17 itself consists of a hard and homogeneous bearing base material, preferably selected from a group comprising Cu-Zn-alloys, such as CuZn31Si, CuSnZn, an AlZn alloy or a CuAl alloy, steel, wherein these alloys can be Other elements such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com