Protecting method and circuit for battery module assembly and disassembly

A battery module and protection circuit technology is applied in the protection and circuit fields of battery module installation and disassembly, and can solve problems such as waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

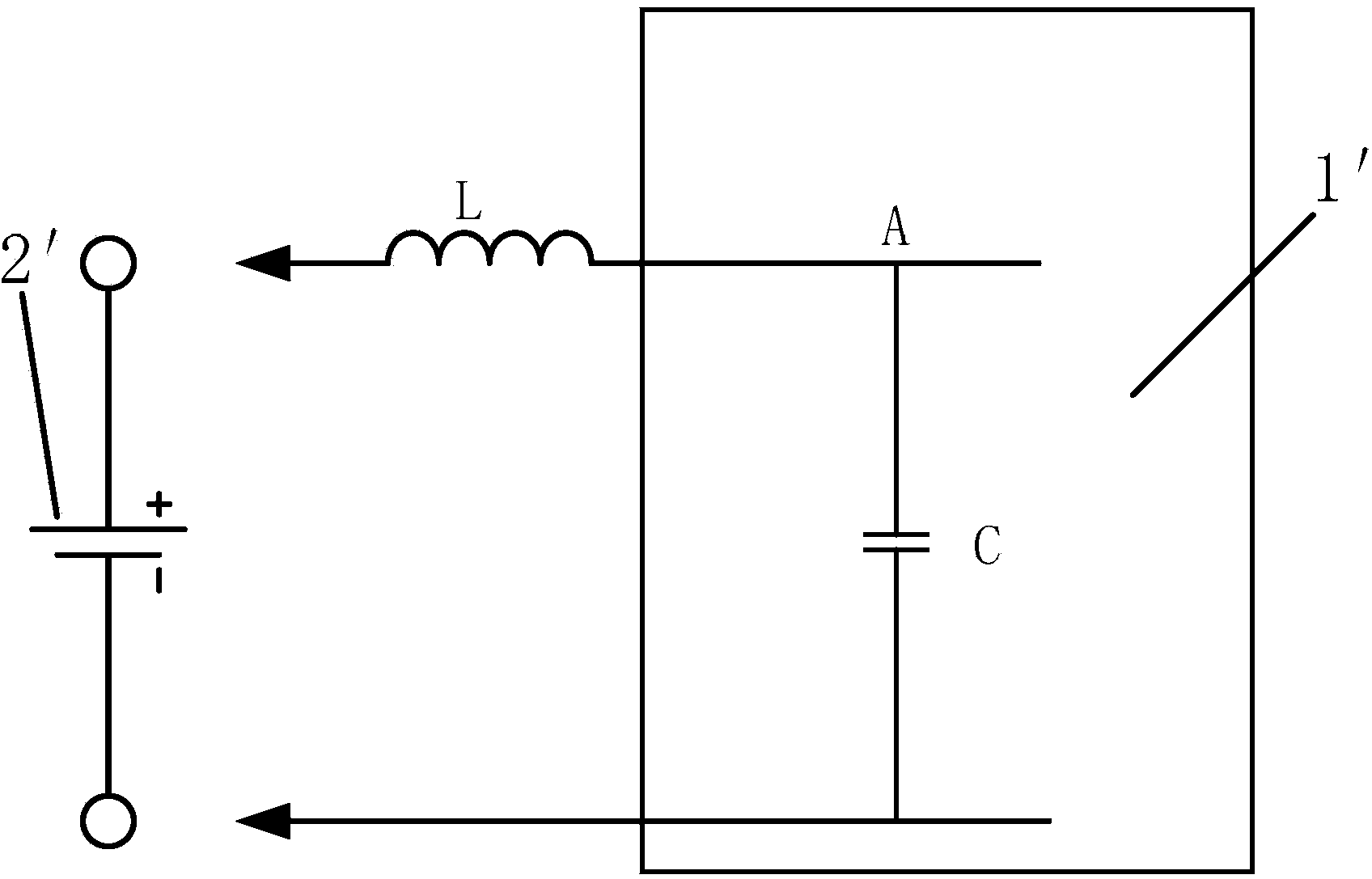

[0023] A protection method for installing and dismounting a battery module, including a battery module 1 and a battery 2, the battery module 1 and the battery 2 can be connected to form a "battery-battery module" loop, and the input capacitance C of the battery module 1 Before adding an adjustment module that can change the loop damping, when the battery module 1 and battery 2 need to be installed or disassembled, the loop damping can be increased by adjusting the adjustment module; when the battery module 1 and battery 2 are connected or the battery module 1 needs to When starting to work in high current mode, the loop damping is reduced by adjusting the adjustment module.

[0024] The adjustment mode of the adjustment module is a manual adjustment mode or a communication adjustment mode.

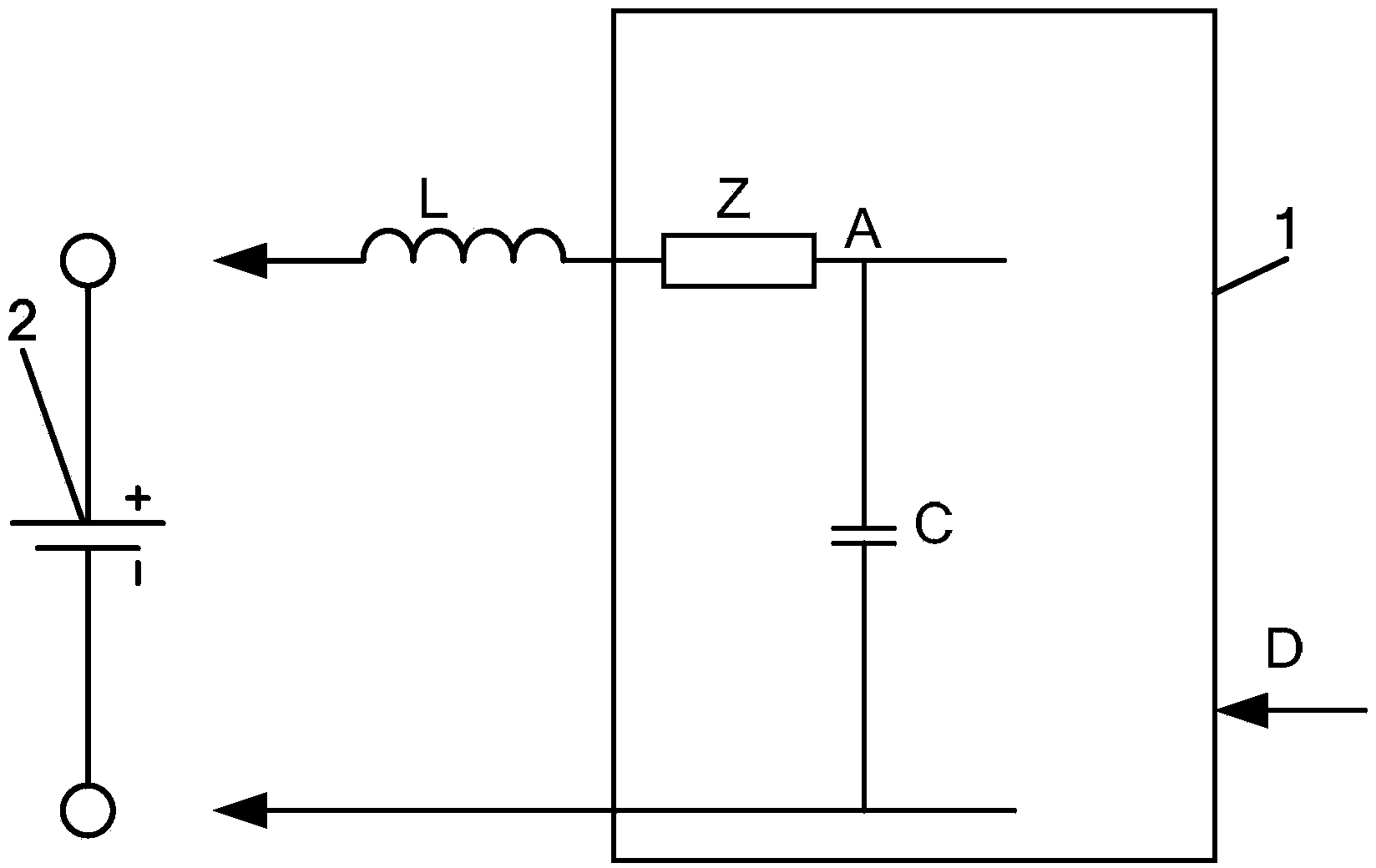

[0025] The adjustment module in this embodiment is a variable impedance Z. When the battery module and the battery need to be installed or disassembled, the variable impedance Z is adjuste...

Embodiment 2

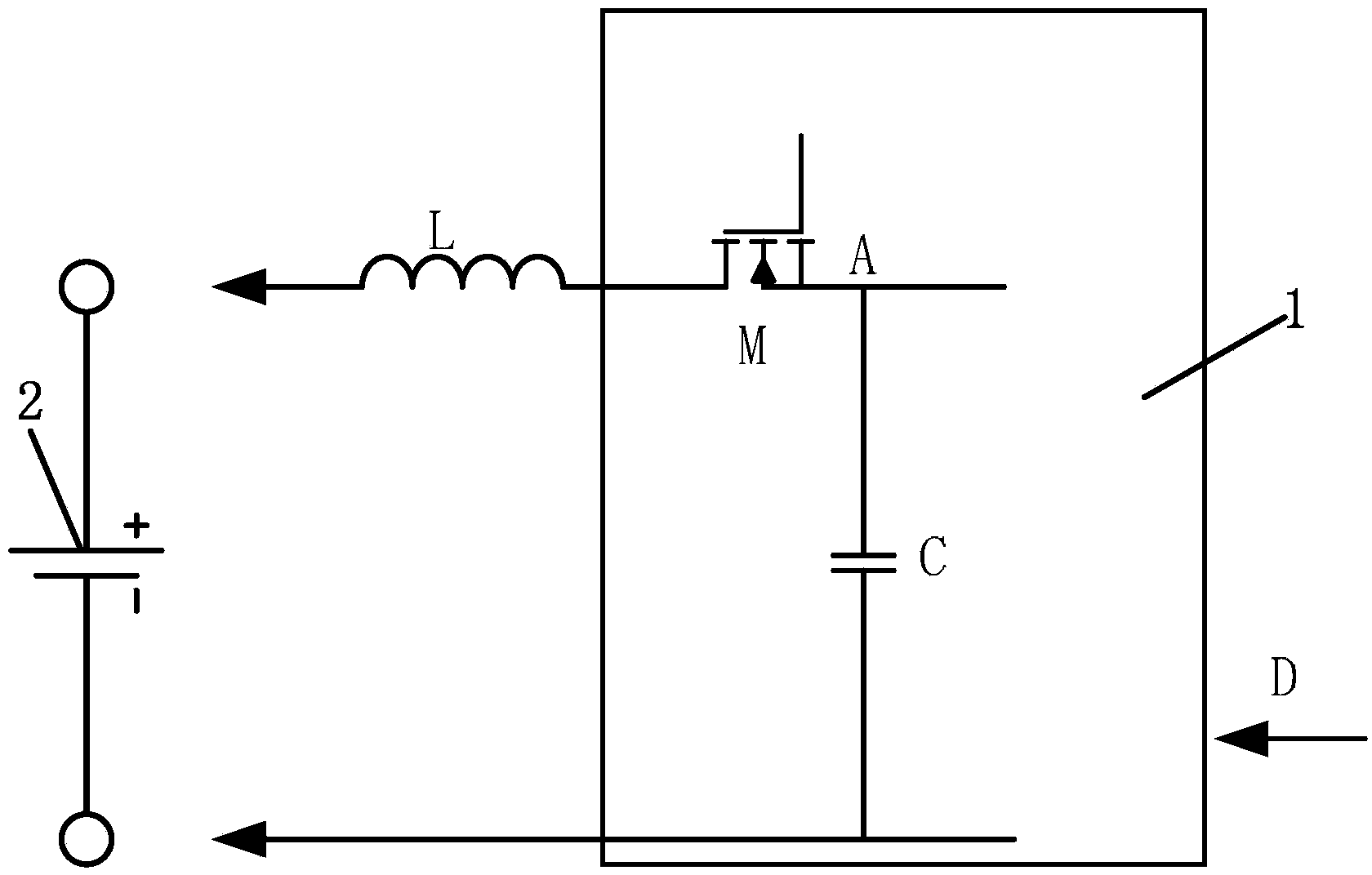

[0029] refer to image 3 , the difference between this embodiment and the first embodiment is that the adjustment module is a power tube M, when the battery module 1 and the battery 2 need to be installed or disassembled, the power tube M is turned into an OFF state, or a high impedance When the battery module 1 is connected to the battery 2 or the battery module 1 needs to start working in the high current mode, the power tube M enters a fully conductive state, or a small impedance state, so that the loop damping state is Little damping.

[0030] In this embodiment, before the battery module 1 is installed or when it needs to be disassembled, the power tube M can be in an OFF state or a high-impedance state, so that the "battery-battery module" loop damping is large enough to ensure that the battery module 1 is connected to the charged battery 2 When , the "battery-battery module" loop does not form a strong oscillation, and the voltage at point A on the input capacitor of t...

Embodiment 3

[0032] refer to Figure 4 The difference between this embodiment and the second embodiment is that the adjustment module includes a power tube M, and a resistor R is connected in parallel between the source and drain of the power tube M. When the battery module 1 and the battery 2 When it needs to be installed or disassembled, turn the power tube M into the OFF state to make the circuit a large damper; when the battery module 1 is connected to the battery 2 or the battery module 1 needs to start working in the high current mode, the power tube M is fully turned on state, making the loop a small damper.

[0033] In this embodiment, before the battery module 1 needs to be installed or disassembled, the power tube M is in the OFF state, and the resistor R connected in parallel between the source and drain terminals of the power tube M ensures that the "battery-battery module" loop damping is large enough to make the battery module 1 contact When the battery is 2, the voltage at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com