Method for rapidly evaluating critical corrosion damage of multilayer coating system

A multi-layer coating and evaluation method technology, applied in the direction of measuring devices, material analysis through electromagnetic means, instruments, etc., can solve the problem of poor light aging resistance, loss of matrix metal protection, and inability to accurately evaluate the critical corrosion damage of the coating system Value and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0016] Step 1: Visually inspect the macroscopic morphology characteristics of the multilayer coating system to be evaluated, preliminarily judge the aging failure degree of the multilayer coating system, and test the remaining thickness of the multilayer coating system with a thickness gauge.

[0017] Step 2: Select the aging failure or serious damage (such as severe pulverization, blistering, cracking, peeling) of the multi-layer coating system as the electrochemical test site, fix the test container, and soak the test site in 3.5% NaCl solution After 20 minutes, the surface of the multi-layer coating system is fully wetted. If the multi-layer coating system has reached the critical corrosion damage state, the corrosion solution will soon soak into the metal substrate. Otherwise, the corrosion solution will be blocked during the invasion process and cannot etch the metal substrate. , to achieve the purpose of in-situ non-destructive testing.

[0018] Step 3: Use the three-ele...

example 1

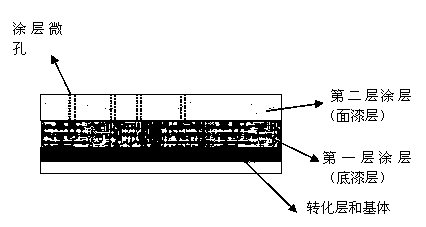

[0025] Example 1: Sulfuric acid anodization + 2 layers of TB06-9 coating

[0026] Base metal: 2D12 aluminum alloy

[0027] Coating method: spraying

[0028] Coating thickness: the first layer of TB06-9 coating 15μm ~30μm

[0029] The second layer of TB06-9 coating 15μm ~30μm

[0030] Total coating thickness: 30μm ~60μm

[0031] The measured thickness of the original coating: 43μm ~52μm

[0032] Test environment: marine atmospheric environment

[0033] Test method: platform outdoor air exposure

[0034] Test time: 2 years

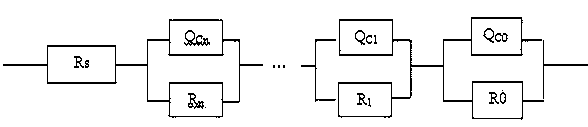

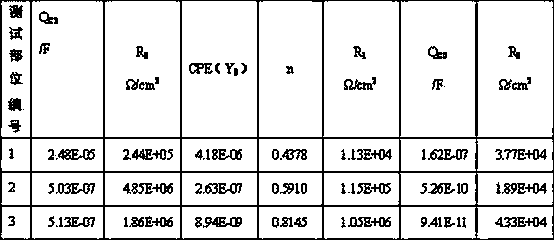

[0035] In this example, the multi-layer coating system is composed of sulfuric acid anodized layer and 2 layers of TB06-9 coating. figure 2 The electrochemical data obtained from the analysis and test of the CM equivalent circuit model shown, the capacitance and impedance values of each coating or conversion layer are shown in Table 1, and the first coating impedance values (R 1 ) down to 10 6 Ω / cm 2. Evaluation results: The multi-l...

example 2

[0038] Example 2: Sulfuric acid anodization + TB06-9 + TS96-71 coating

[0039] Coating substrate: 2D12 aluminum alloy

[0040] Coating method: spraying

[0041] Coating thickness: TB06-9 coating 15μm ~30μm

[0042] TS96-71 coating 40μm ~70μm

[0043] Total coating thickness: 55μm~100μm

[0044] The measured thickness of the original coating: 80μm~90μm

[0045] Test environment: marine atmospheric environment

[0046] Test method: platform outdoor air exposure

[0047] Test time: 2 years

[0048] In this example, the multi-layer coating system is composed of sulfuric acid anodized layer, TB06-9 coating and TS96-71 coating. figure 2 The electrochemical data obtained by analyzing the CM equivalent circuit model shown in the test, the capacitance and impedance values of each coating or conversion layer are shown in Table 2, and the second layer of coating at the second and third test sites in the three test sites Impedance value (R 2 ) has a large drop, les...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com