Screw testing machine

A detection machine and screw technology, which is applied in the direction of optical testing for flaws/defects, etc., can solve problems such as the inability to detect screw internal threads, achieve the effect of reducing detection errors and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

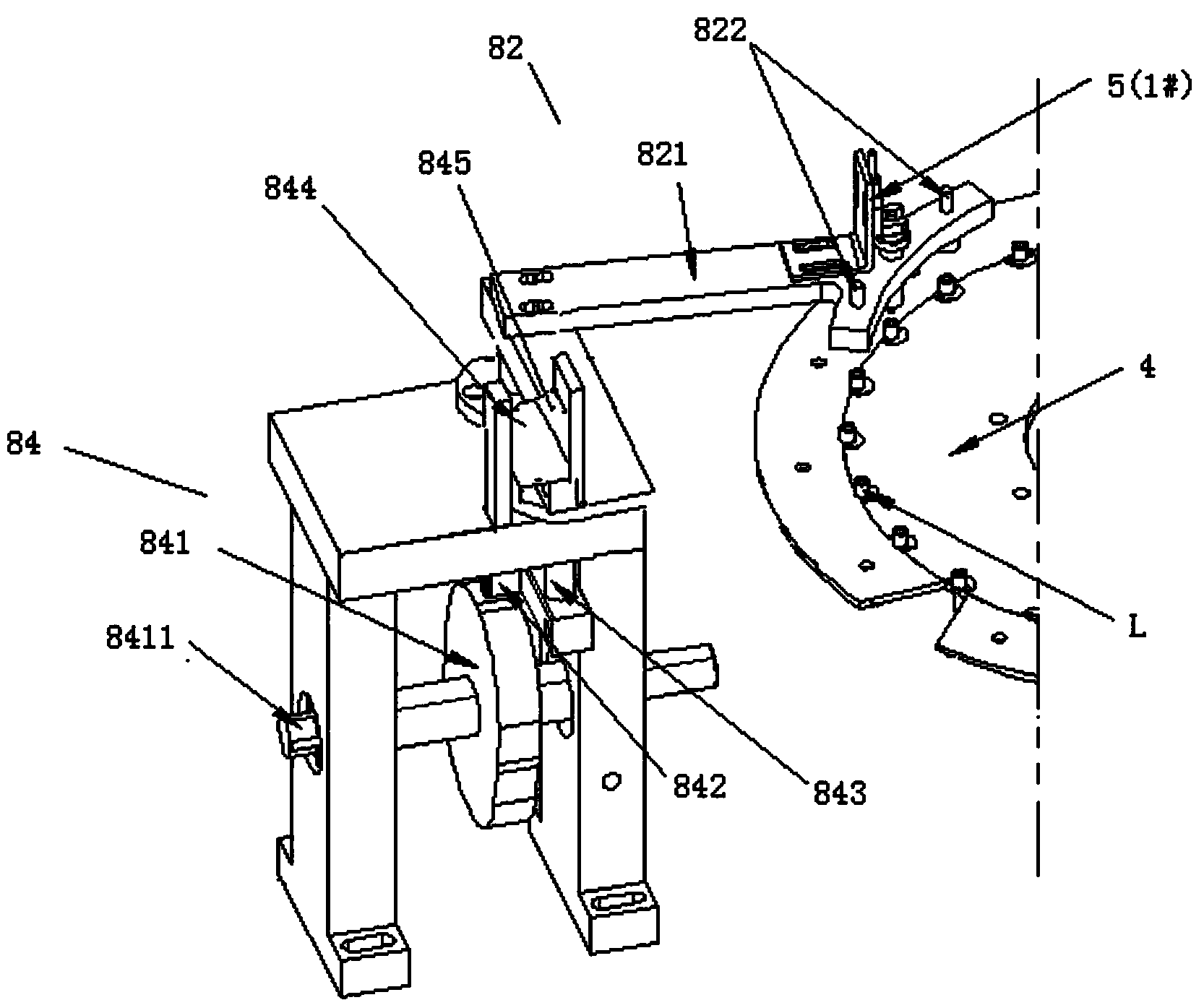

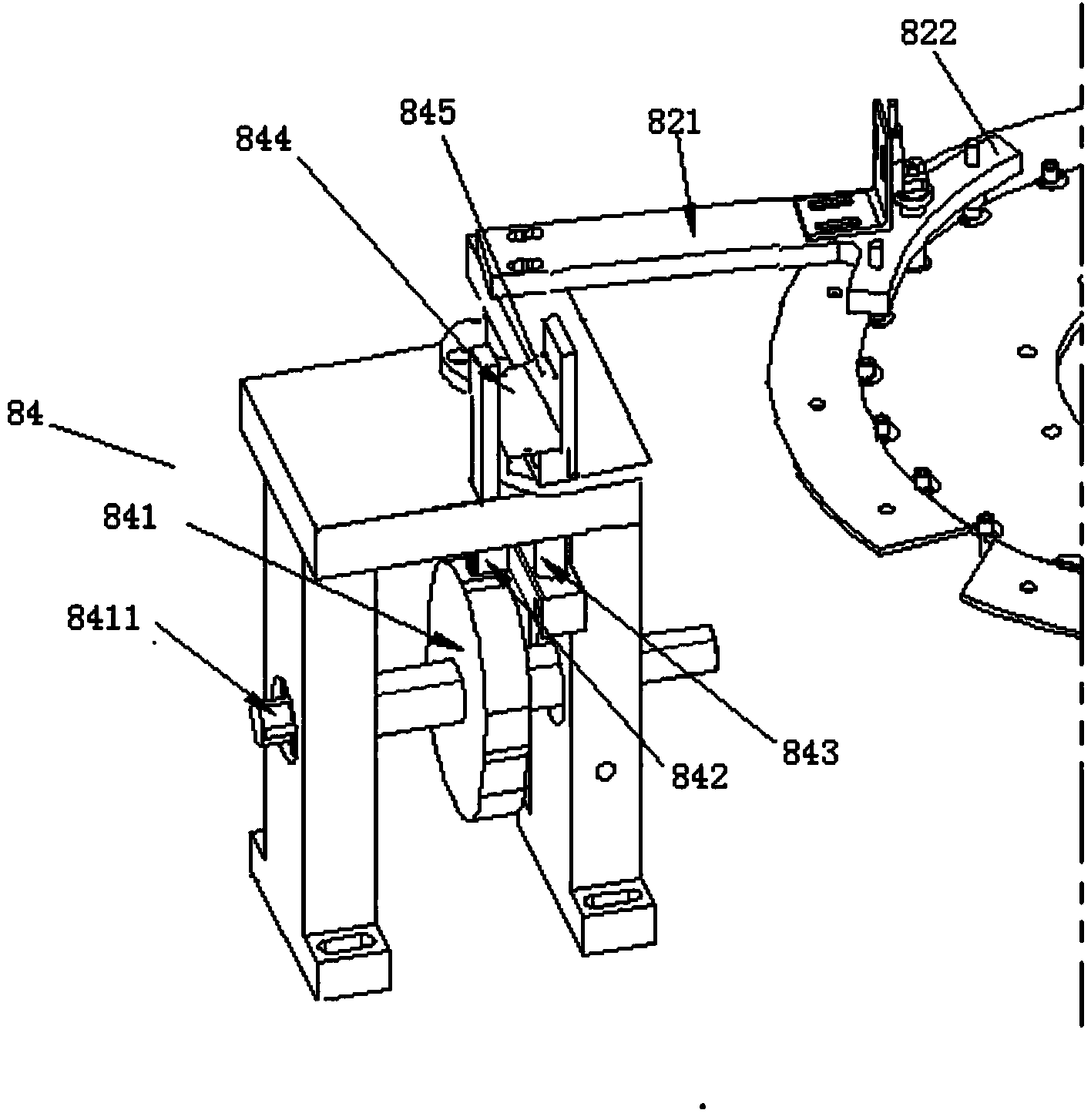

[0035] The solution of the first embodiment mainly solves the problem of detection accuracy caused by the deflection of the screw on the turntable. For this reason, the screw detection machine of this embodiment is provided with a screw position correction mechanism. The screw position correction mechanism and the cam divider of the turntable 4 ( Figure 8 Middle 43) linkage, after the cam divider drives the turntable to rotate one position, it will automatically press down the screw to flatten the screw head on the turntable 4, so as to correct the state of the screw and avoid the detection caused by the abnormal position of the screw error. Hereinafter, this embodiment will be specifically described.

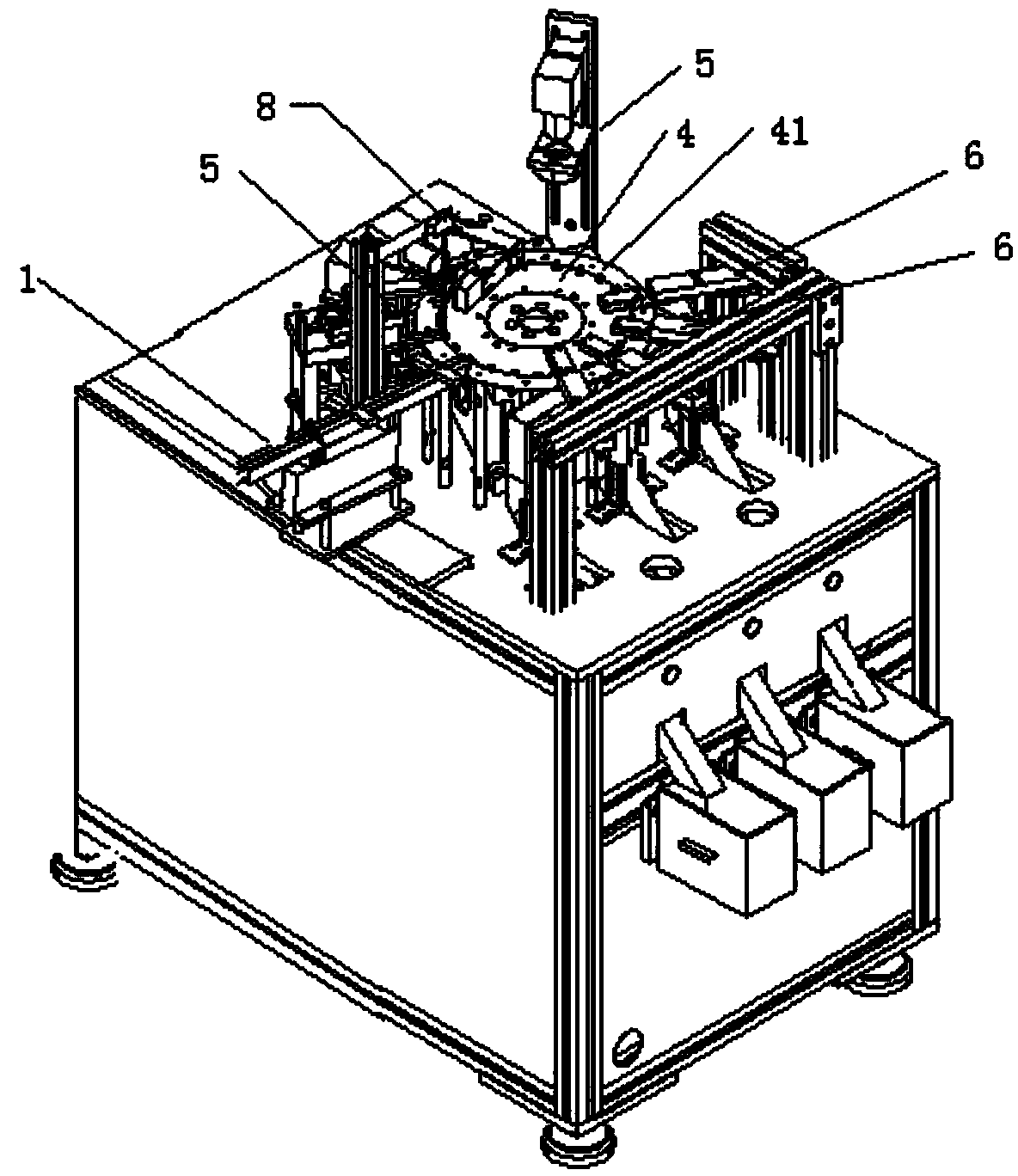

[0036] figure 1 A schematic diagram of a screw inspection machine of the present invention is shown. The screw inspection machine includes a screw loading mechanism 1 , a turntable 4 , a screw defect detector 5 , a plurality of screw recovery mechanisms 6 and a screw posi...

no. 2 approach

[0047] The solution of the second embodiment further improves the solution of the first embodiment for the problem of detection accuracy caused by the deflection of the screw on the turntable 4 . The screw position correction mechanism of the screw detection machine in this embodiment pushes the screw L horizontally after the cam divider drives the turntable to rotate one position, and at the same time automatically presses down the screw to flatten the screw head on the turntable 4 , to correct the state of the screw and avoid the detection error caused by the abnormal position of the screw. Hereinafter, this embodiment will be specifically described.

[0048] The screw inspection machine also includes a screw loading mechanism 1 , a turntable 4 , a screw defect detector 5 , a plurality of screw recovery mechanisms 6 and a screw position correction mechanism 8 . Although figure 1 The number of screw defect detectors 5 marked in is one, but in fact, corresponding to the par...

no. 3 approach

[0059] In this embodiment, the screw placement holes on the turntable are improved, so that the turntable does not need to be replaced when detecting screws of different types or specifications, reducing the use cost of the equipment.

[0060] Figure 6 A part of the back surface of the turntable on which the screw carrier is mounted in the screw inspection machine according to the third embodiment of the present invention is shown. Figure 7 A partial front view of a turntable on which a screw carrier is mounted is shown in a screw inspection machine according to a third embodiment of the present invention.

[0061] Such as Figure 6 and Figure 7 As shown, a screw carrier 42 can be provided in each screw placement hole 41 of the turntable 4 . The three side walls of the screw carrier 42 except one side of the outer edge of the turntable 4 are respectively provided with distance-adjusting screws 422, and the front ends of the distance-adjusting screws 422 are provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com