Boiler combustion test furnace

A boiler combustion and combustion test technology, applied to measuring devices, instruments, etc., can solve the problems of many heating surfaces and the inability to simulate power station combustion, etc., and achieve the effect of environmental friendliness, environmental protection and large-scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention are described in detail below, and the present embodiment is carried out under the premise of the present invention, has provided detailed implementation and specific operation process, but protection scope of the present invention is not limited to following embodiment .

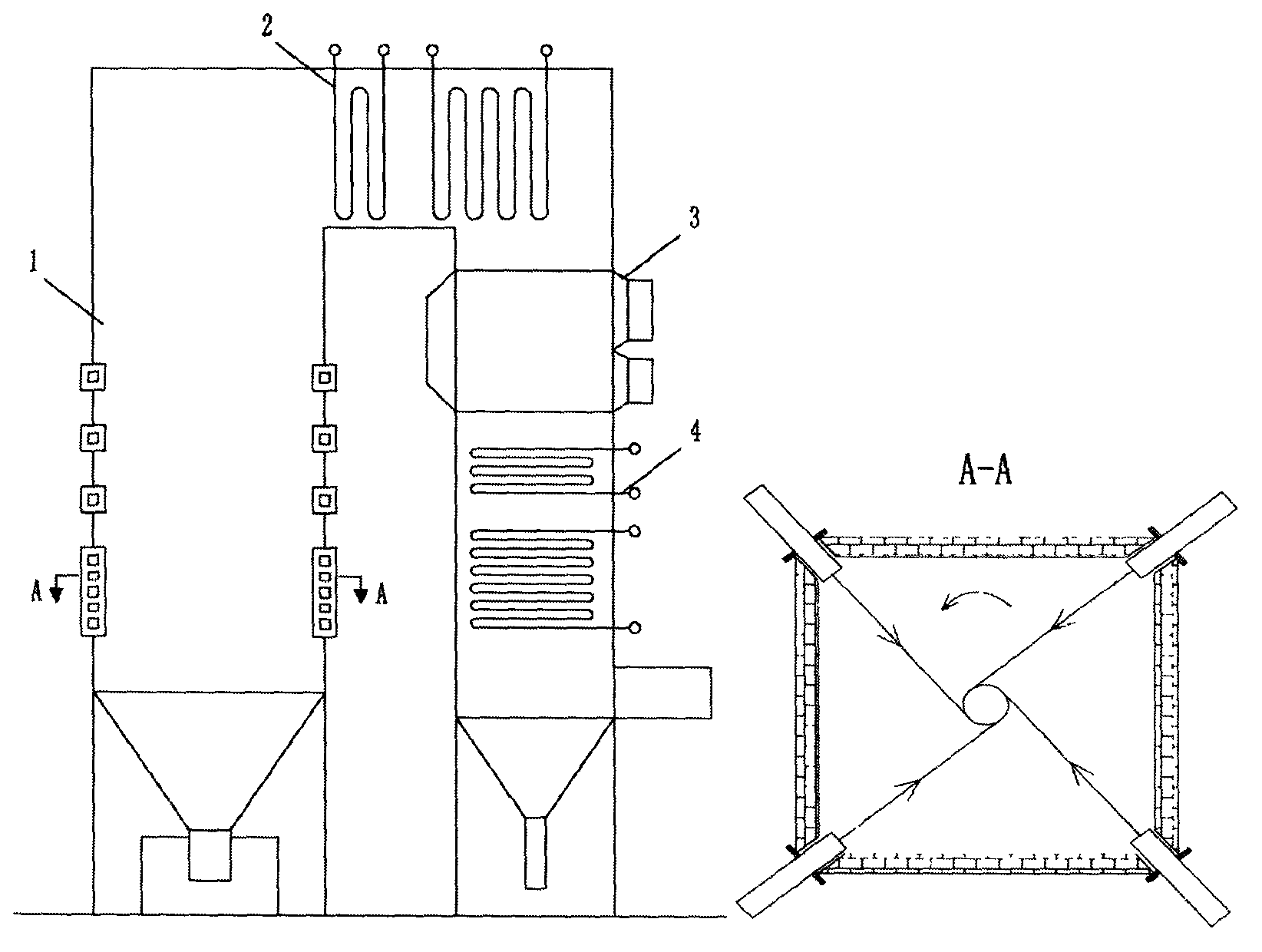

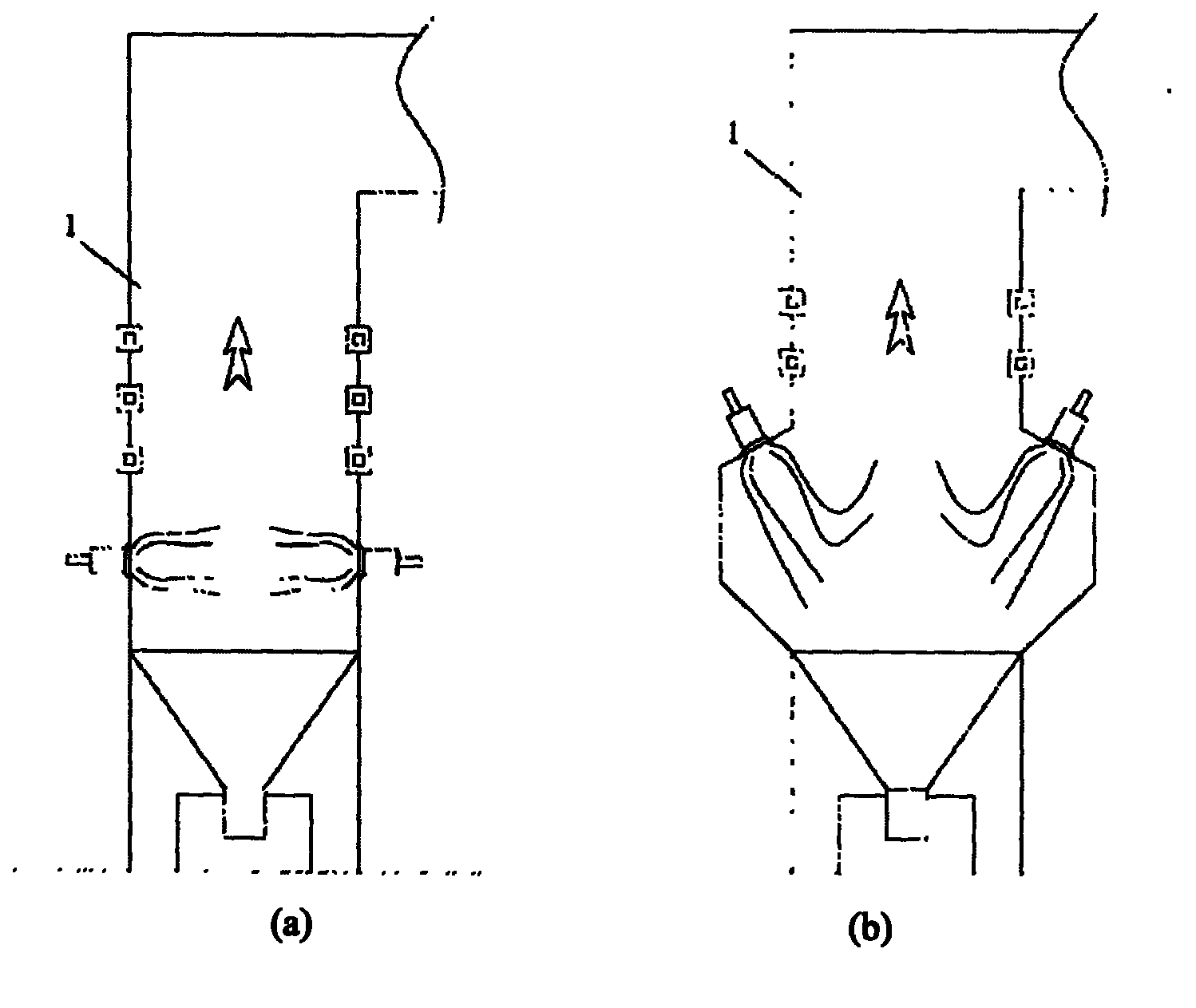

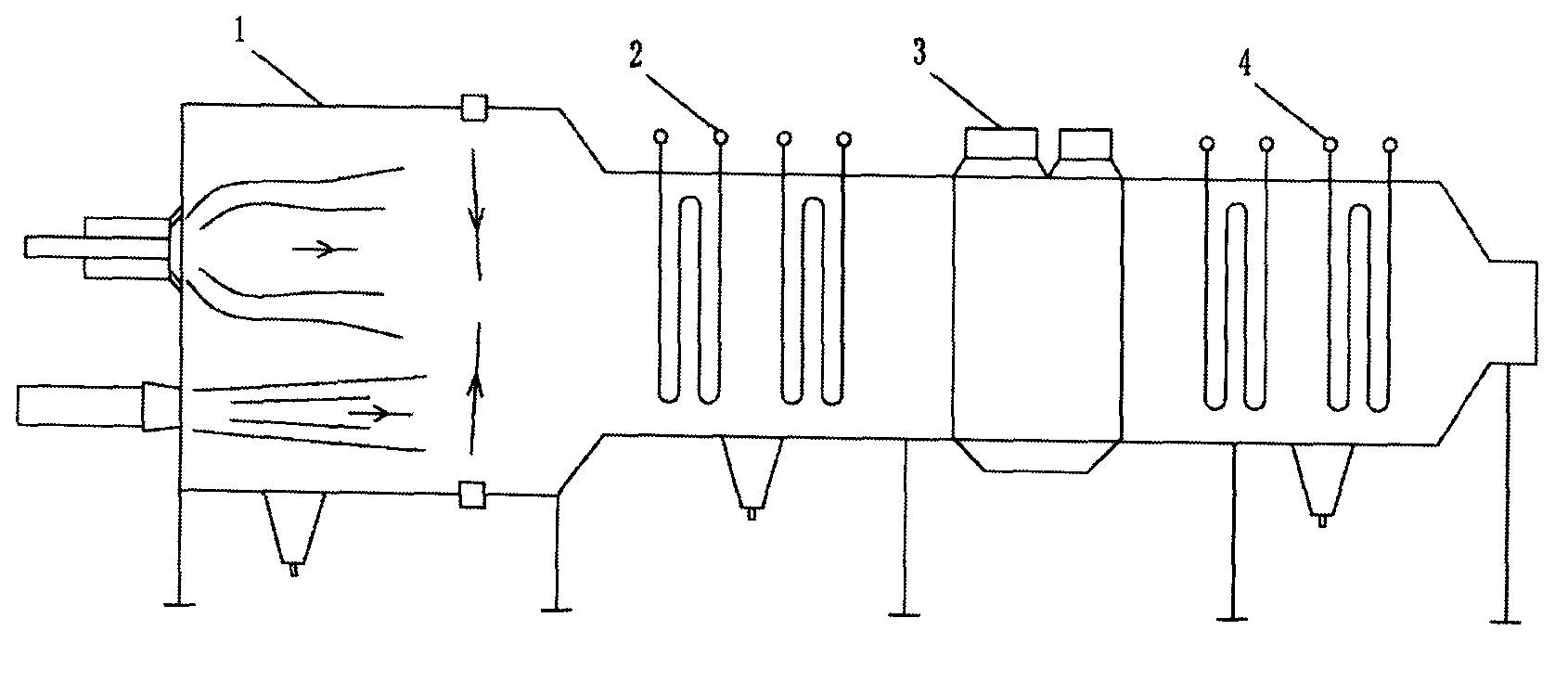

[0025] Such as Figure 4 As shown, this embodiment includes: interval furnace 1, removable graded high-temperature convection heating surface 2, high-temperature air preheater 3, graded low-temperature economizer 4, combustion medium 5, and other structures 6.

[0026] The spaced furnace 1 includes: a heat-resistant furnace wall 101, a water-cooled furnace wall 102, and a supporting furnace roof 103, wherein: the heat-resistant furnace wall 101 and the water-cooled furnace wall 102 are arranged in layers and at intervals, and the supporting furnace roof is supported by water-cooled support tubes. Hot furnace wall composition.

[0027] The detachable and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistance temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com