An intelligent submersible pump operation record and maintenance early warning system

A technology for submersible electric pumps and operation records, which is applied in pump control, liquid variable displacement machinery, machines/engines, etc. It can solve problems such as loss, inability to determine the frequency and time of product use, and insufficient accuracy of product quality information to achieve The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

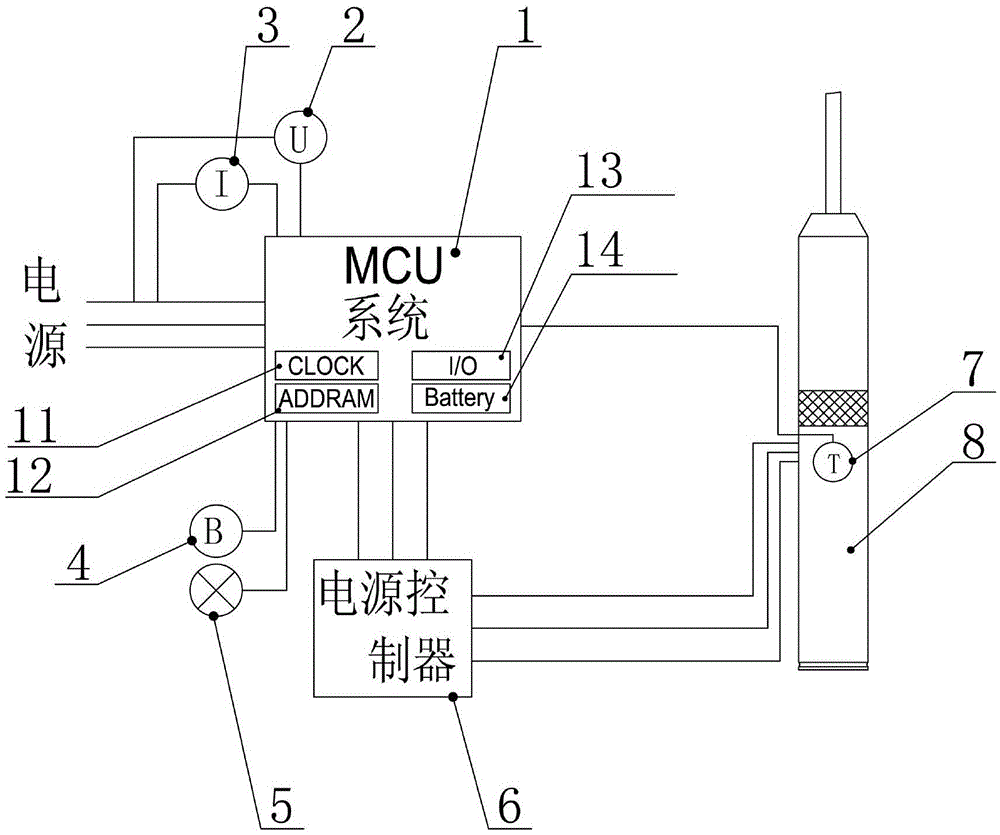

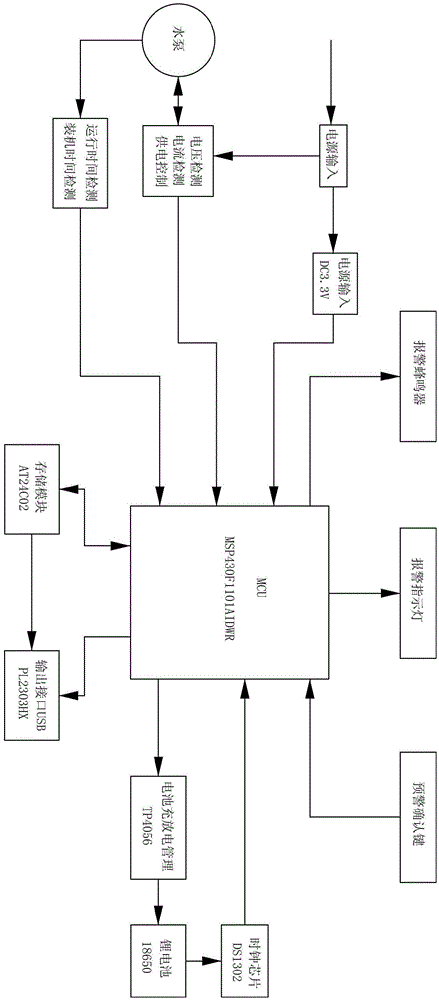

[0030] A brief schematic diagram of the working circuit of an intelligent submersible pump operation record and maintenance early warning system of the present invention is as follows: figure 1 with figure 2 As shown, it includes a microcomputer computer 1, an alarm output device 5 and a submersible electric pump 8;

[0031] Described microcomputer computer comprises clock module 11, storage module 12, data input and output interface 13 and battery module 14;

[0032] The data input and output interface 13 is used to collect the operation data of the submersible electric pump 8 and control the work of the alarm output device 5;

[0033] The battery module 14 is used to provide internal power supply to the microcomputer computer 1;

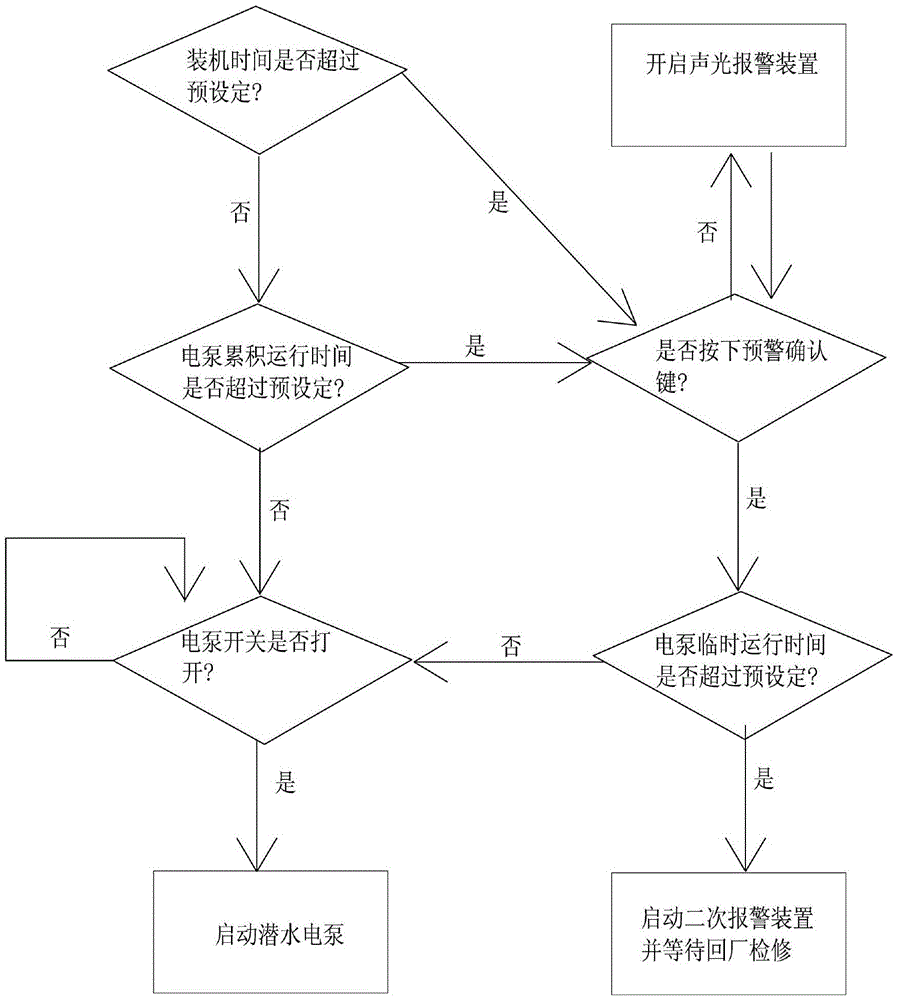

[0034] The clock module 11 is used to calculate the installed time of the submersible electric pump and the cumulative running time of the submersible electric pump in combination with the data input by the data input and output interface 13;

...

Embodiment 2

[0046] An intelligent submersible electric pump is provided with the operation record and maintenance early warning system of the intelligent submersible electric pump in Embodiment 1.

[0047] Beneficial effects of the present invention: early warning for electric pump maintenance, effectively protecting the electric pump and improving the overall service life of the electric pump; facilitating the collection of actual use data of the electric pump, facilitating the definition of the warranty period of the electric pump and the follow-up design Optimization provides reference data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com