Capacitor discharge type electronic igniter for engine

An electronic igniter and capacitor discharge technology, which is applied in the electronic field, can solve the problems of large trigger current fluctuations, limited application range, and high false trigger rate, and achieve small trigger current fluctuations, omission of trigger coils, and low false trigger rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

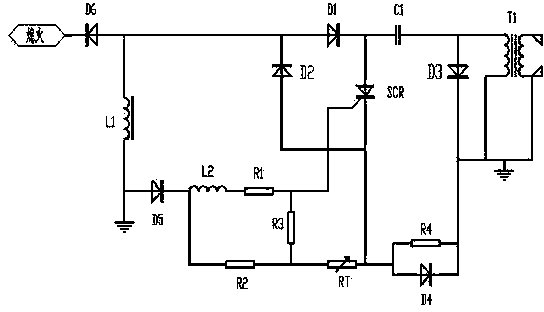

[0012] Referring to accompanying drawing 1, what the embodiment of the present invention shows is the capacitive discharge type electronic igniter used on the outboard motor, including generating coil, charging and discharging circuit, ignition angle control circuit, ignition coil, wherein, the generating coil L1 of the magneto , which is the AC voltage generated by cutting the lines of force when the magnetic field of the magneto rotates. It is not only the power supply of the whole igniter but also the trigger signal source.

[0013] When the alternating voltage in L1 is up positive and down negative, the rectification and charging circuit composed of diode D1, capacitor C1 and ignition coil T1 completes a charging process to capacitor C1. When the voltage in L1 is lower positive and upper negative, it is rectified by diode D5, filtered by inductor L2 and current-limited by resistor R1, and the trigger pulse is added to the control electrode of the thyristor SCR. At this tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com