Filling drill bit for drilling type coal mining machine

A technology for filling drill bits and shearers, which is used in filling materials, earth-moving drilling, cutting machinery, etc., can solve the problems of heavy equipment, large volume, inability to use thin and ultra-thin coal seam goafs, etc., to save underground The space and structure are reasonable and simple, and the effect of avoiding the collapse of the goaf

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

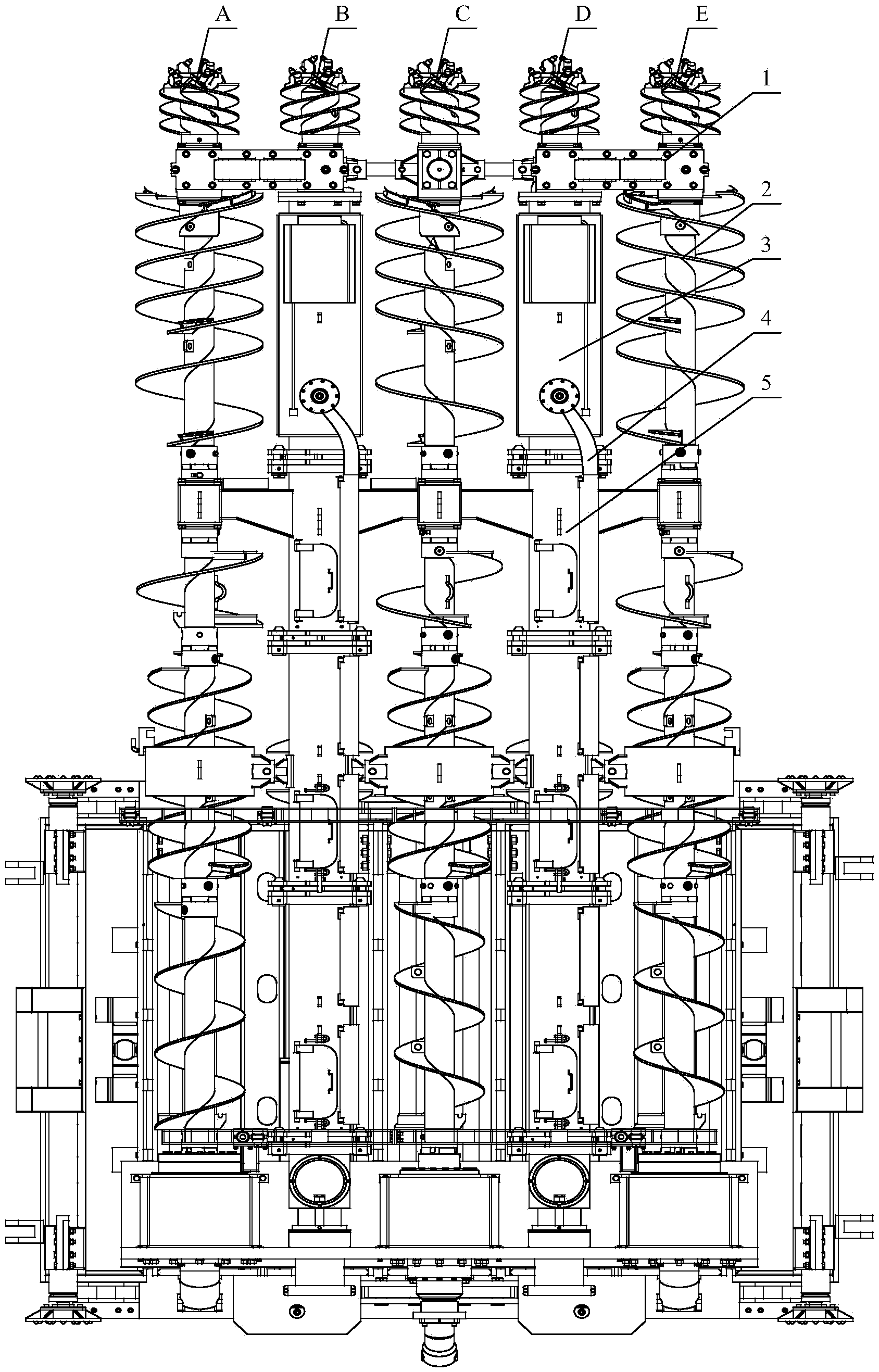

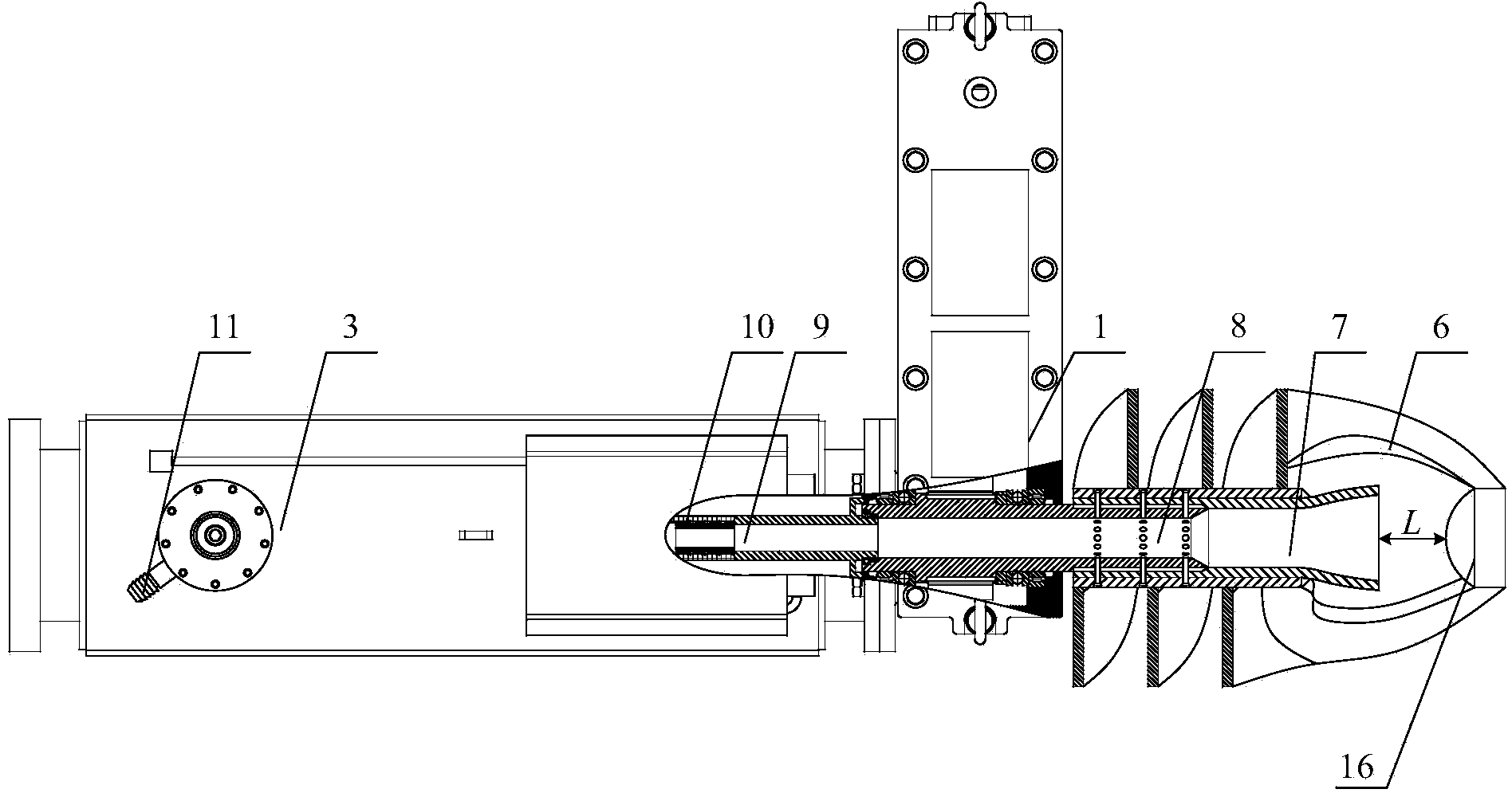

[0013] The filling drill bit for drilling shearer of the present invention is mainly composed of 5 drill bits A, B, C, D, E, transmission box 1, ventilation box 3, delivery pipe 4, ventilation pipe 5 and supporting The connecting device constitutes. Among the five drill bits, drill bits A, C, and E are connected to the drill pipe 2, and drill bits B and D are connected to the ventilation box 3. The two drill bits connected to the ventilation box 3 include a drill bit 6, a filling pipe 7, and a hollow gear Shaft 8 and supporting connection device, drill bit 6, filling pipe 7 and hollow gear shaft 8 are fixed by bolts, the hub of drill bit 6 is a hollow structure, filling tube 7 is installed in the hollow hub of drill bit 6, and the drill bit 6 at the front end of filling tube 7 The end plate is welded with a hemispherical splitter plate 16, the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com