Process and device for producing sodium silicate

A sodium silicate and process technology, applied in the field of sodium silicate production process and equipment, can solve the problems of wide explosion limit, large loss of raw materials, high risk, etc., and achieve precise temperature control, small loss of raw materials and good product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

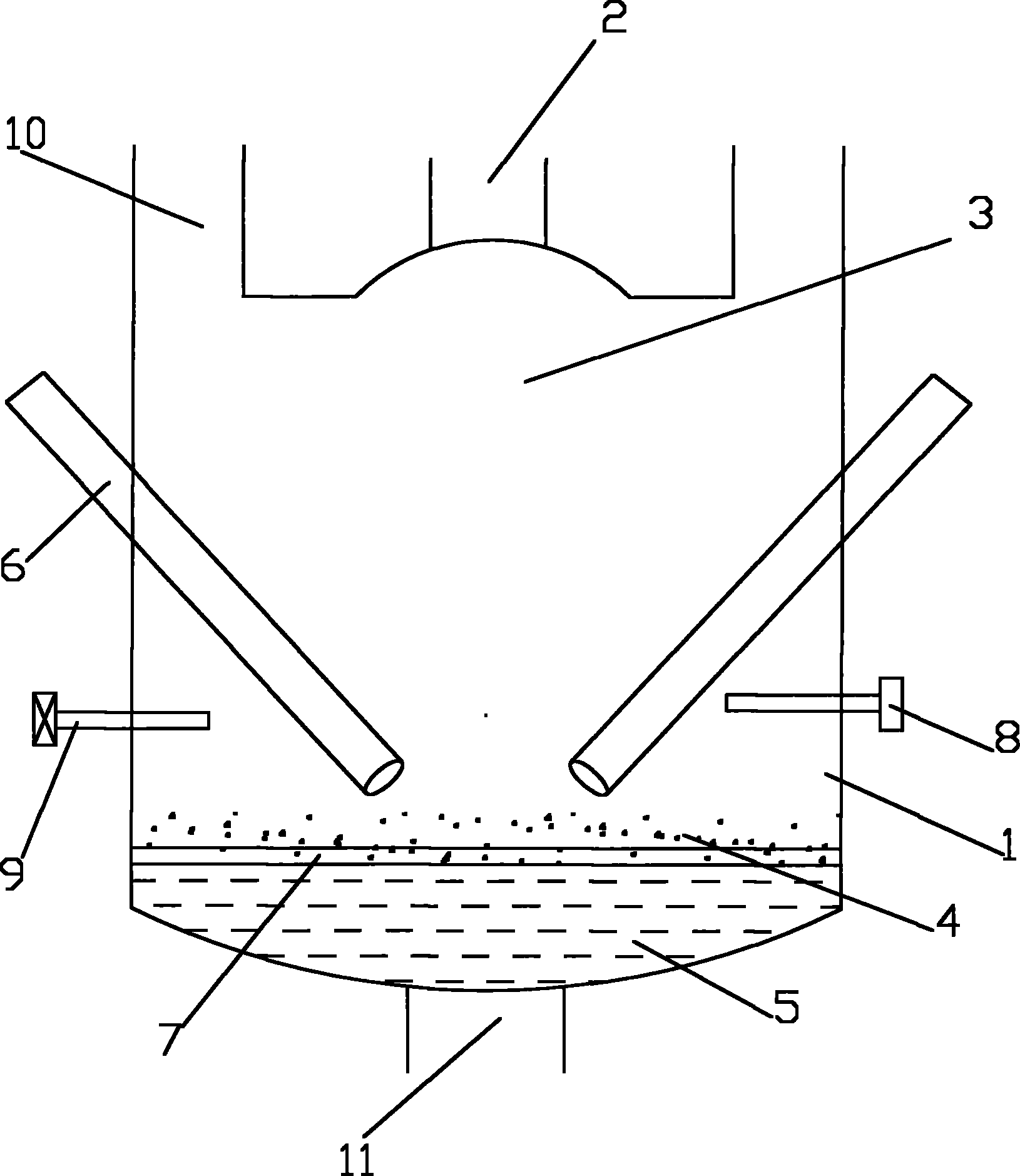

[0020] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0021] A kind of technology of producing sodium silicate of the present invention, comprises the following steps:

[0022] 1) Stir quartz sand and soda ash according to the proportion to form a mixture; sodium silicate is also called water glass, and its modulus above 3 is called "neutral" water glass, and its modulus below 3 is called "neutral" water glass. Alkaline" water glass, after removing part of the water in the sand silo, the quartz sand with uniform water enters the receiving port, and is sent to the silo through the elevator, and then enters the sand alkali weighing hopper through the vibrating hopper vibrating feeder. After weighing, enter the mixer and mix evenly to form a mixture of raw materials. The formula feeding amount (on a dry basis) is calculated as follows: M1=M×M2×60 / 106 In the formula: M1: the mass Kg of quartz sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com