Production method of functional film and web conveying device

A manufacturing method and conveying device technology, applied in the direction of thin material handling, transportation and packaging, winding strips, etc., can solve the problems of easy generation of wrinkles, high retention force of material guide rollers, etc., and achieve the effect of inhibiting sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Next, examples will be given to describe the present invention in more detail. However, the present invention is by no means limited to these Examples.

[0067]

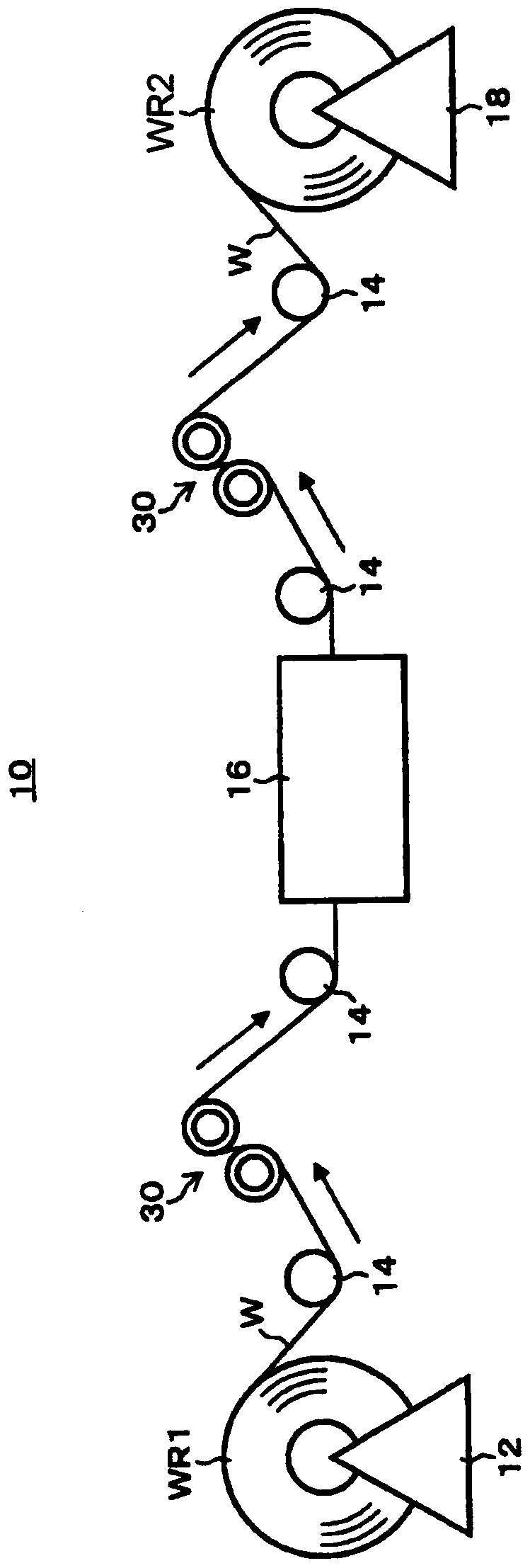

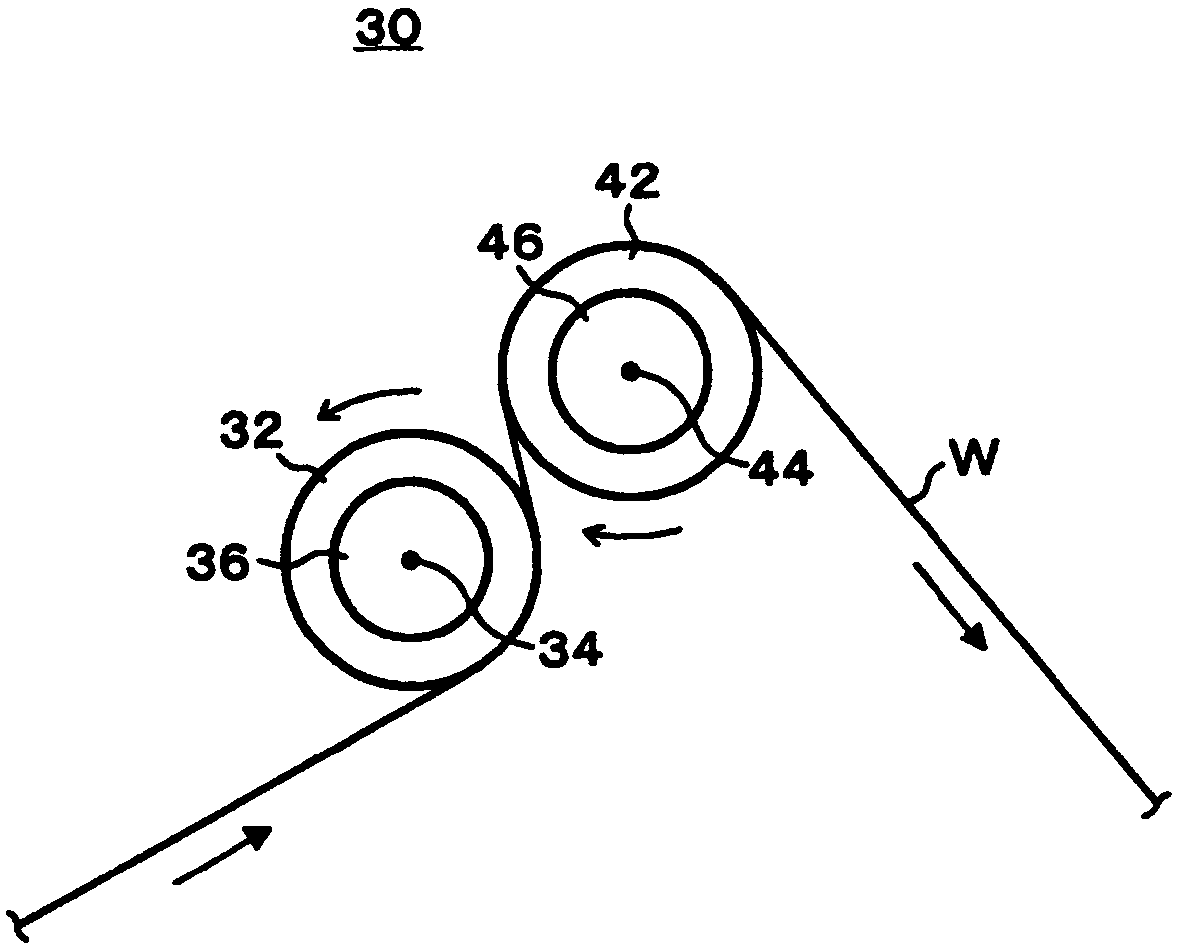

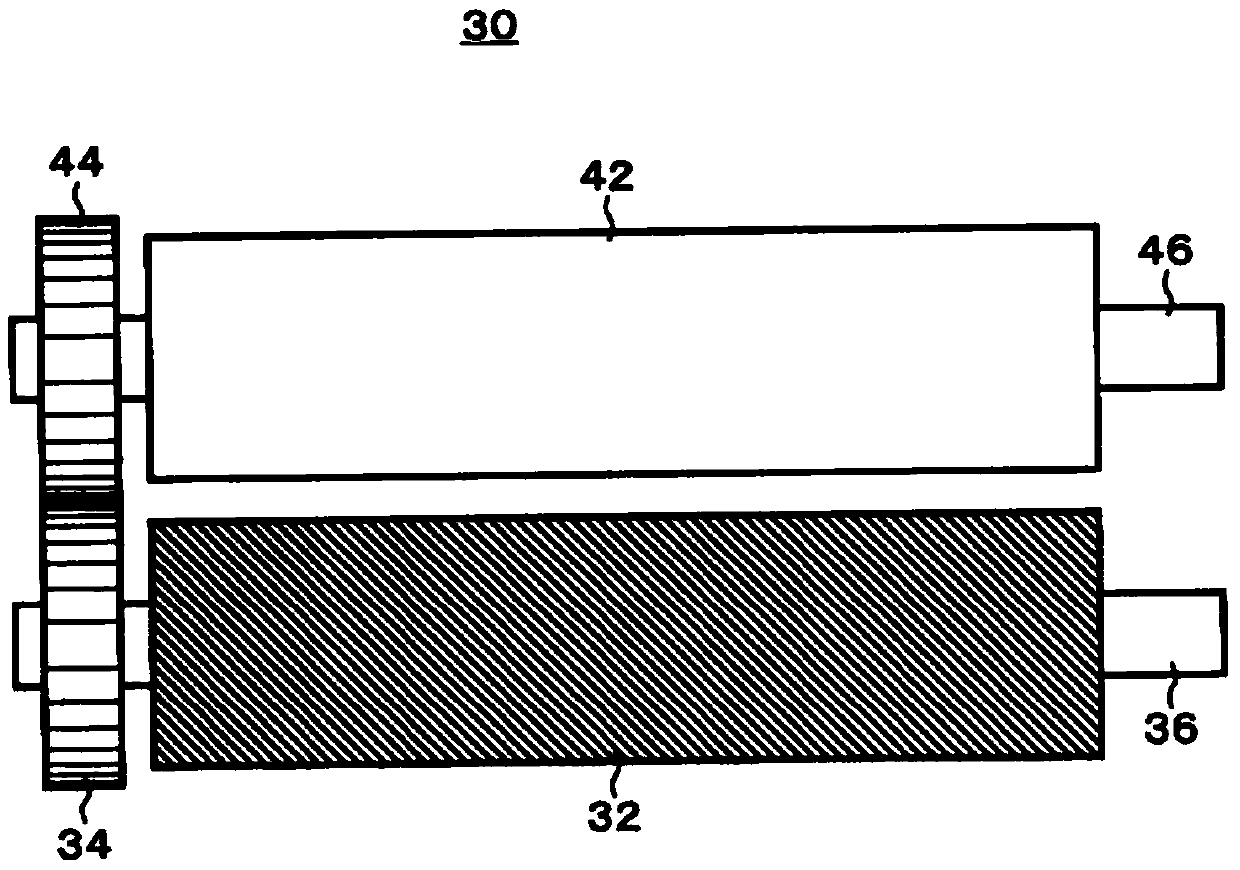

[0068] In a manufacturing facility of an optical compensation film for a liquid crystal display panel, the web conveying device according to the present embodiment is arranged before and after a coating section. The sheet conveyor will have 90mm outer diameter ( : diameter), a grooved roll with a length of 1850 mm was used as the first roll. The grooves formed on the outer peripheral surface of the first roller had a width of 1 mm, a depth of 0.2 mm, and a pitch of 20 mm. In addition, the web conveying device will have a smooth outer peripheral surface, with A flat roll having an outer diameter of 90 mm and a length of 1850 mm was used as the second roll. The outer peripheral surface of the second roll had a smoothness of Ra0.6 μm.

[0069] A magnetic gear is used as a transmission mechanism for tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com