Loading system and loading method

A technology of feeding and material processing, which is applied in the field of feeding system, can solve the problems of poor working environment at the opening of bags, threats to the health of workers, and affecting production efficiency, so as to avoid secondary pollution, save labor costs, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

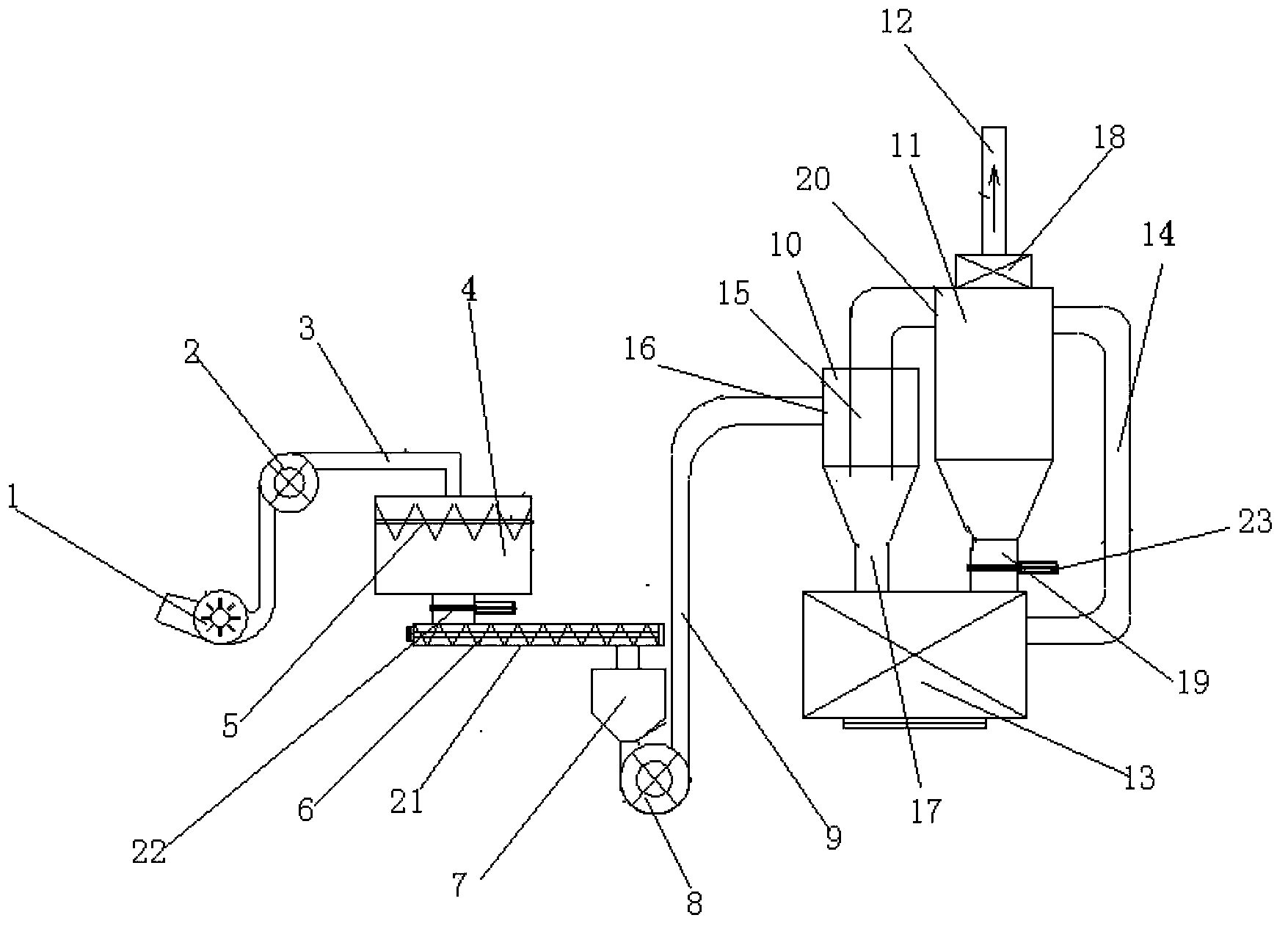

[0056] In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the present embodiment and the features in the embodiments can be combined arbitrarily with each other.

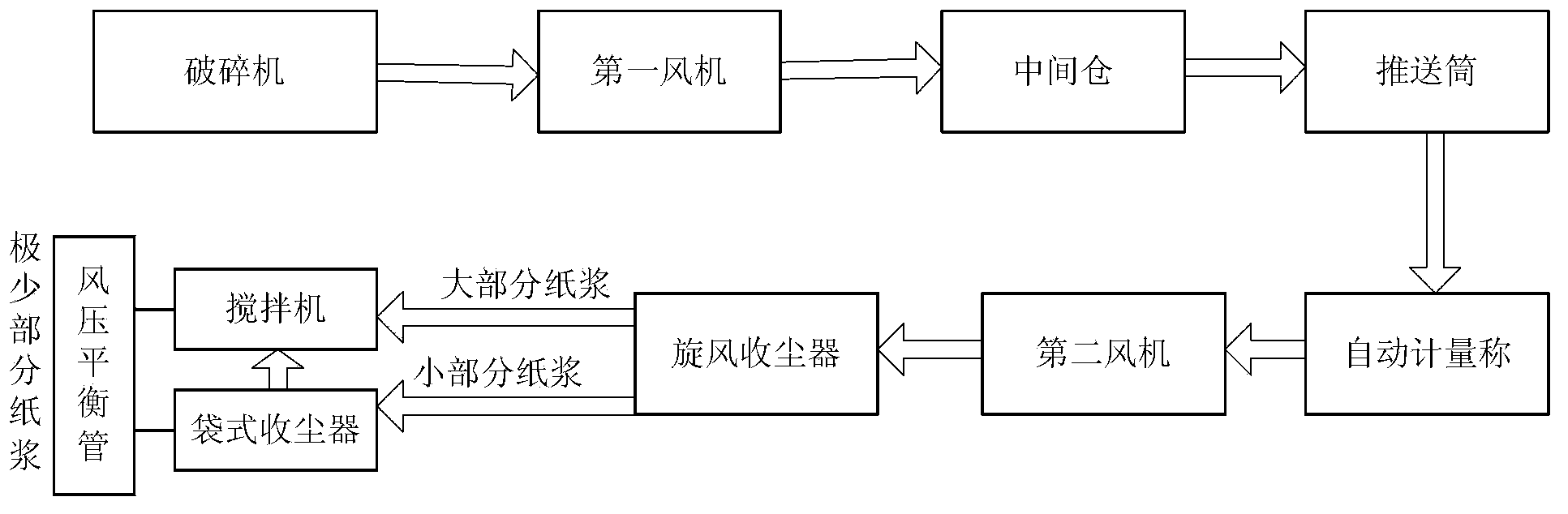

[0057] The invention has a wide range of uses. During the production and processing of materials, some materials (such as pulp, wood, plastics, etc.) Potential safety hazard, the core idea of the present invention is to first crush the material into powder, and then use the exhaust device to transport the crushed material through the airtight transmission channel, which greatly improves the production efficiency and effectively avoids secondary pollution.

[0058] Take the feeding of pulp as an example to describe the present invention in detail below:

[0059] Device embodiment

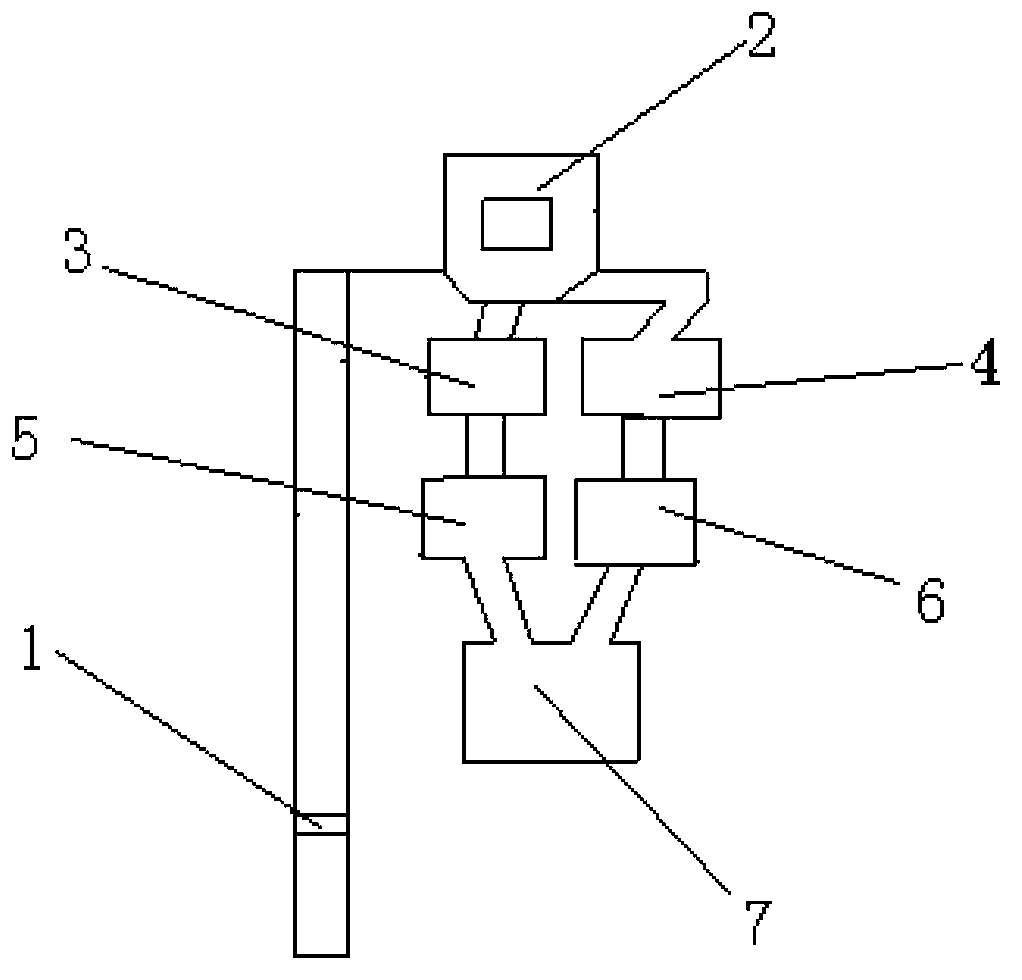

[0060] Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com