Method for physically simulating sectional hydrofracture of different well types of perforated well shafts

A technology of hydraulic fracturing and physical simulation, which is applied in the direction of wellbore/well components, earthwork drilling and production, and production fluid, etc. Interference between fracturing and multi-stage hydraulic fracturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A physical simulation method for staged hydraulic fracturing of perforated wellbores of different well types, comprising the following steps:

[0071] (1) Process the simulated wellbore, and arrange perforation holes on the simulated wellbore wall;

[0072] (2) Prefabricate the simulated wellbore in step (1) into the artificial core sample, and use the true triaxial hydraulic fracturing device system (such as Figure 6 shown) to carry out hydraulic fracturing physical simulation experiments;

[0073] (3) Through the hydraulic fracturing physical simulation experiment in step (2), observe the hydraulic fracture initiation and expansion form at the perforation holes on the simulated wellbore wall.

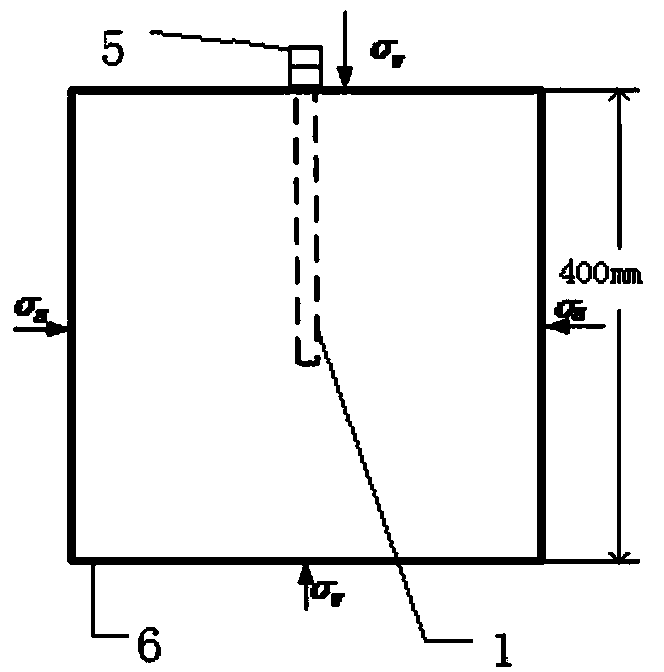

[0074] In this embodiment, the simulated wellbore is a vertical well simulated wellbore, and the simulated vertical wellbore is composed of a wellbore head 5 and a vertical well simulated wellbore body 1. The wellbore head 5 includes a concave sealing groove, and the wellbore...

Embodiment 2

[0099] A physical simulation method for staged hydraulic fracturing of perforated wellbores of different well types, comprising the following steps:

[0100] (1) Process the simulated wellbore, and arrange perforation holes on the simulated wellbore wall;

[0101] (2) Prefabricate the simulated wellbore in step (1) into the artificial core sample, and use the true triaxial hydraulic fracturing device system to carry out the hydraulic fracturing physical simulation experiment;

[0102] (3) Through the hydraulic fracturing physical simulation experiment in step (2), observe the hydraulic fracture initiation and expansion form at the perforation holes on the simulated wellbore wall.

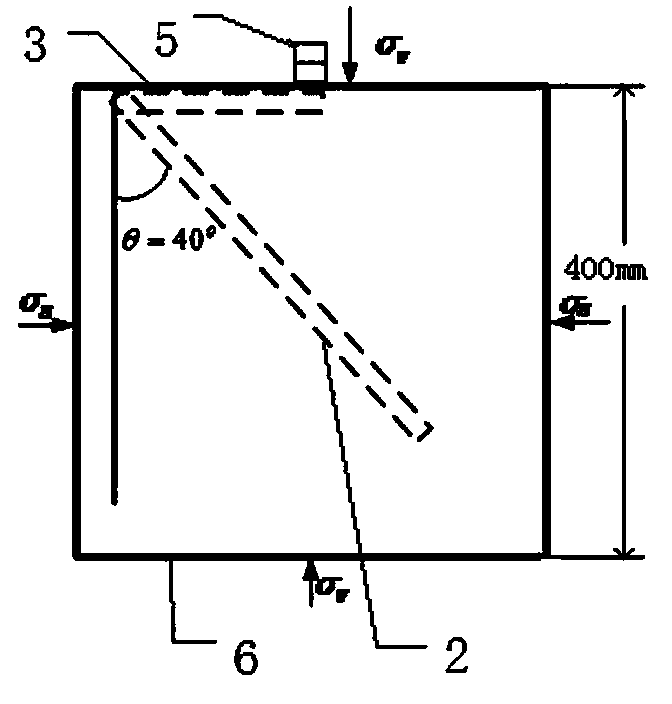

[0103] In this embodiment, the simulated wellbore is a simulated wellbore for a deviated well, and the simulated wellbore for an inclined well includes a wellbore head 5, a simulated wellbore 3 for an auxiliary horizontal section, and a simulated wellbore 2 for an inclined section; the wellbore head...

Embodiment 3

[0129] A physical simulation method for staged hydraulic fracturing of perforated wellbores of different well types, comprising the following steps:

[0130] (1) Process the simulated wellbore, and arrange perforation holes on the simulated wellbore wall;

[0131] (2) Prefabricate the simulated wellbore in step (1) into the artificial core sample, and use the true triaxial hydraulic fracturing device system to carry out the hydraulic fracturing physical simulation experiment;

[0132] (3) Through the hydraulic fracturing physical simulation experiment in step (2), observe the hydraulic fracture initiation and expansion form at the perforation holes on the simulated wellbore wall.

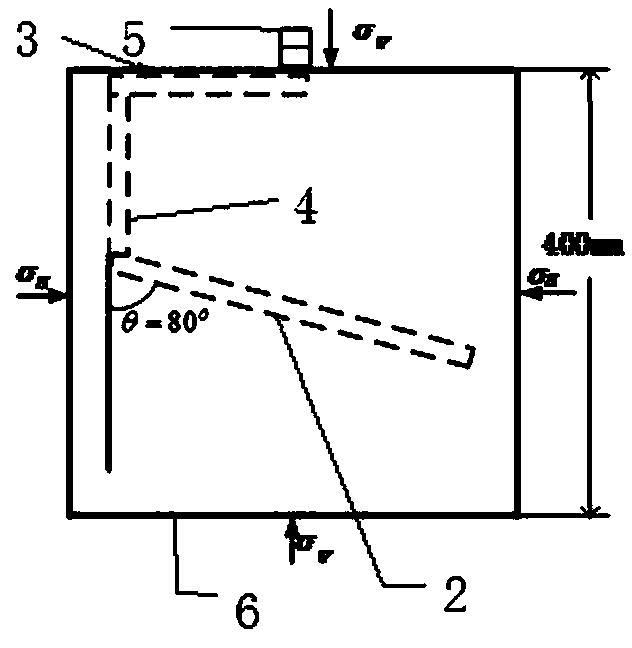

[0133] In this embodiment, the simulated wellbore is a simulated wellbore for a deviated well, and the simulated wellbore for an inclined well includes a wellbore head 5, a simulated wellbore 3 for an auxiliary horizontal section, a simulated wellbore 4 for an auxiliary vertical section, and a simul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com