Wall mortar multi-gun automatic spraying distribution system

A distribution system and automatic spraying technology, which is applied in construction, building construction, etc., can solve the problems of construction workers such as high labor intensity, limited work efficiency, and impact on construction, so as to facilitate control of material consumption, convenient cleaning and maintenance, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

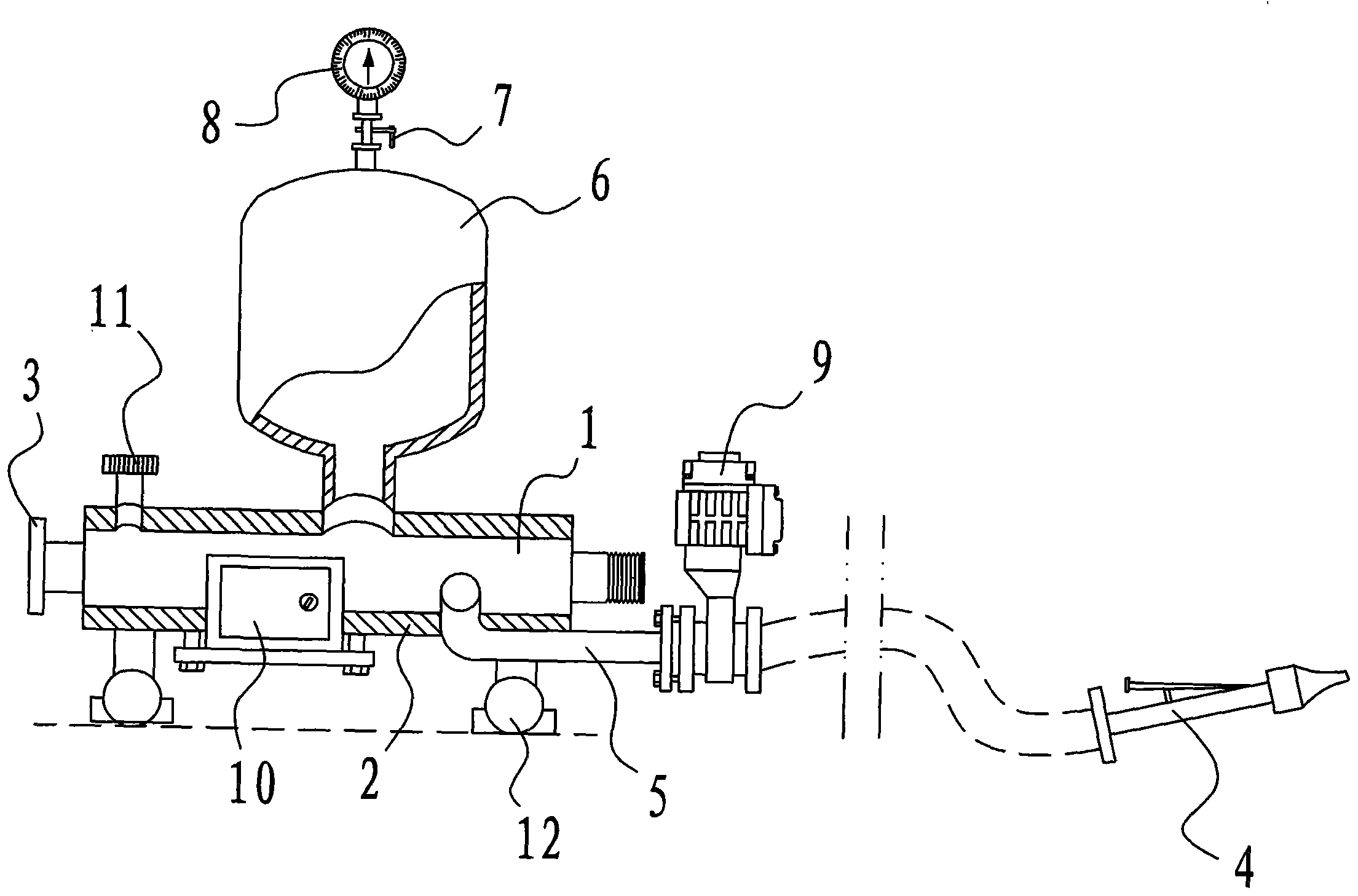

[0022] Such as figure 1 As shown, a wall mortar multi-gun automatic spray distribution system includes a base 2 with a feed chamber 1, and the base 2 is provided with a feed port 3 connected to the main distribution system and a socket for connecting the spray gun 4 A plurality of discharge ports 5, the discharge ports 5 communicate with the feed chamber 1, and the base 2 is provided with a piston connected to the feed chamber 1 to balance the mortar delivery pump to cause instantaneous material delivery. The pressure in the pipeline is missing, and the mortar is supplied intermittently to the gas storage tank 6, and the gas storage tank 6 is provided with a pressure gauge 8 with a regulating valve 7. Each discharge port 5 is provided with a remote control electric regulating valve 9 for controlling the flow rate of the mortar, and the remote c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com