Back groove type hanging piece assembly of stone materials and installation method

A pendant, back groove technology, applied in building components, covering/lining, walls, etc., can solve the problems of installation requirements, construction progress and construction safety back bolt structure, small contact force surface, low pullout force, etc. , to achieve the effect of convenient construction, fast progress and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

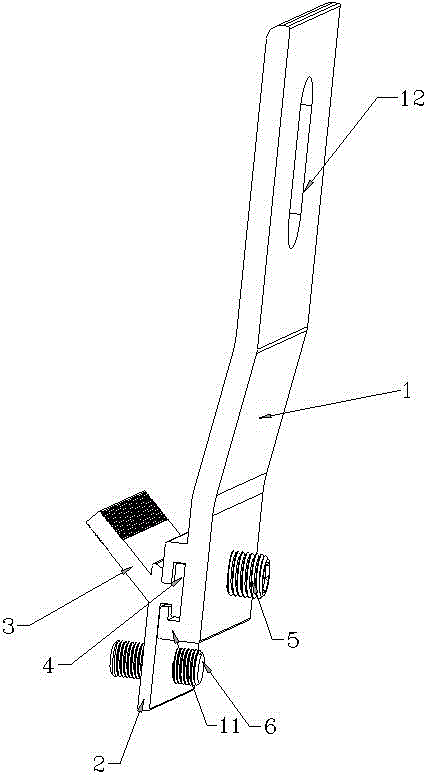

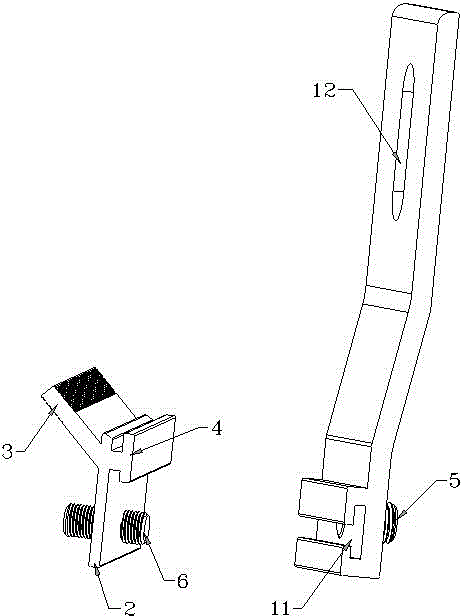

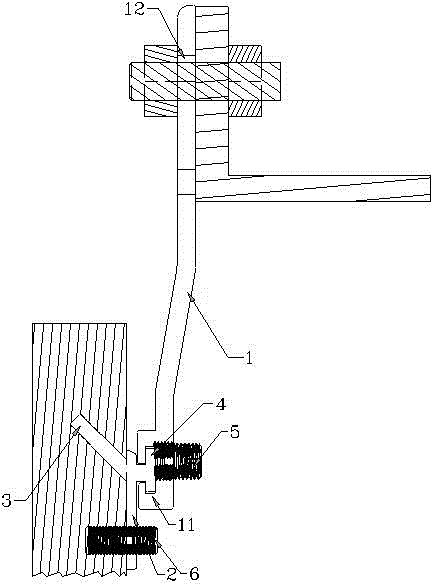

[0024] Refer to attached figure 1 to attach image 3 , as shown in the accompanying drawings, the present invention provides a combination of stone back groove type pendants, including an embedded support and a Z-shaped pendant 1. The embedded support includes a plane guide plate 2 that guides the support and is obliquely arranged The upper pick is embedded into the hook plate 3, and after the upper pick is inserted into the hook plate 3 and goes deep into the inclined groove of the veneer, the whole plane guide plate 2 is just attached to the veneer. Preferably, the upper pick is embedded into the hook plate 3 and the plane guide plate 2 It is at an included angle of 45°. After the angle is set, the upper pick embedded hook plate 3 is sn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com