Method for preparing bimodal polyethylene adjustable in molecular weight distribution by use of metallocene system

A molecular weight distribution, bimodal polyethylene technology, applied in the production of bulk chemicals, etc., can solve problems such as the reduction of metallocene catalyst activity, and achieve the effect of effective regulation and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

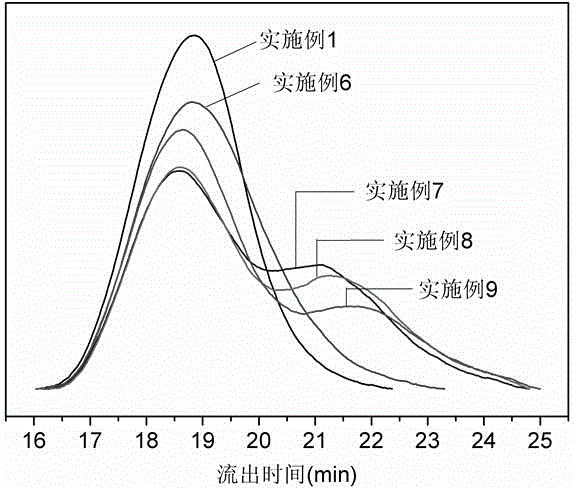

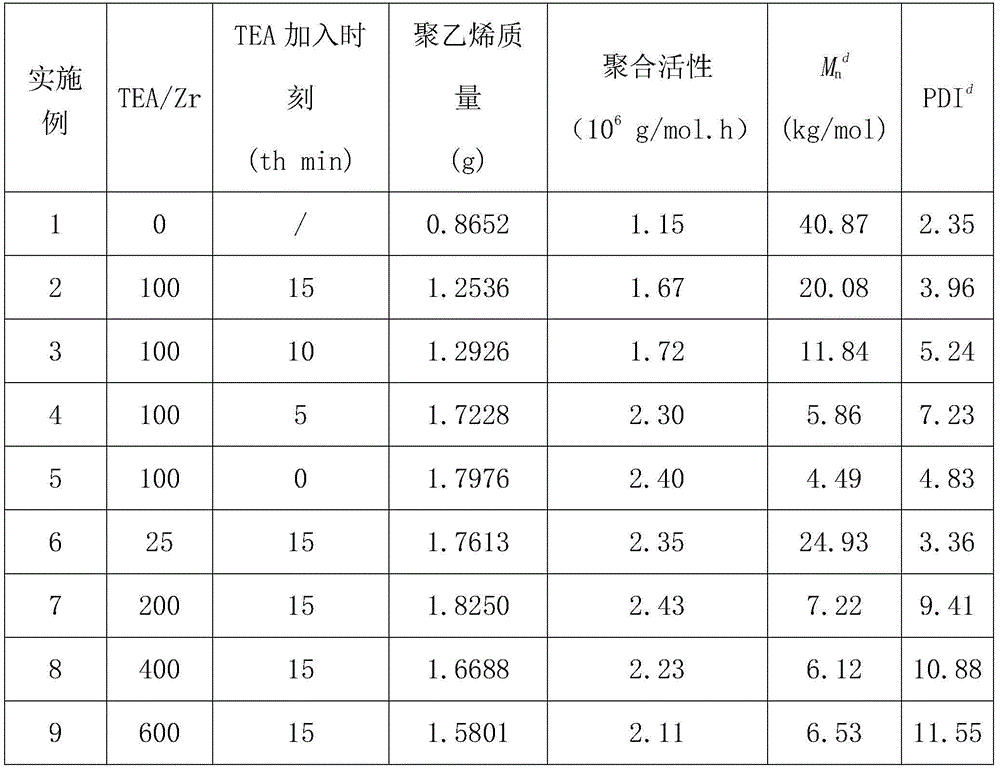

Examples

Embodiment 1

[0030] Ethylene polymerization was carried out in a three-neck flask equipped with ethylene gas inlet, electromagnetic stirring and vacuum port. The dry three-necked flask was baked and exhausted, then introduced with ethylene gas, and then vacuumed, and the vacuuming and ventilation operations were repeated three times. Add toluene according to the requirements of the experiment, and start stirring. When the ethylene gas is dissolved and saturated in the toluene solution, add methylalumoxane (MAO) and rac-vinyl bis-indenyl zirconium dichloride (rac-Et(Ind) 2 ZrCl 2 ) The catalyst starts ethylene polymerization, and the total volume of the reaction solution V total = 50ml. The concentration of the metallocene catalyst of rac-vinyl bis-indenyl zirconium dichloride in the reaction solution is 30 μmol / L.

[0031] After the reaction was over, the aeration was stopped, and acidified ethanol was added to terminate the reaction. After the polymer product was filtered and washed, ...

Embodiment 2

[0034] The specific implementation is the same as 1, adding triethylaluminum solution (TEA) in the 15th minute of ethylene polymerization, so that the total volume of the reaction solution V total =50ml, wherein the concentration of the metallocene catalyst of rac-vinyl bis-indenyl zirconium dichloride in the reaction solution was 30 μmol / L, and the reaction was continued. After the reaction was over, the aeration was stopped, and acidified ethanol was added to terminate the reaction. After the polymer product was filtered and washed, it was vacuum-dried and weighed. The molar ratio of each component in the catalyst system is: Zr / Al MAO / TEA (all peers understand) = 1:1000:100.

[0035] The characteristics of the bimodal polyethylene obtained in the experiment are: number average molecular weight (M n ) is 20.08kg / mol, polydispersity index (PDI) is 3.96; Catalyst activity is 1.67 ' 10 6 g PE / (mol.h.atm).

Embodiment 3

[0037] The specific implementation steps are the same as in Example 2, and TEA is added in the 10th minute of ethylene polymerization.

[0038] The ratio of each component of the catalyst system is: Zr / Al MAO / TEA=1 / 1000 / 100. Synthetic polymers are characterized by: number average molecular weight (M n )=11.84kg / mol, PDI=5.24; Catalyst activity: 1.72'10 6 gPE / (mol.h.atm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com