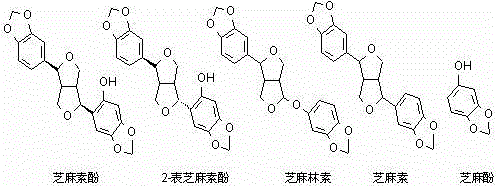

A kind of method that catalyzes sesamolin to prepare sesamol

A technology of sesamol and sesamolin, which is applied in the field of preparation of sesamol, can solve problems such as unsatisfactory industrial production, high technical level requirements for equipment, limited amount of sesamol, etc., and achieve low cost, green process and chemical properties stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for catalyzing sesalin for the preparation of sesaminol, specifically: taking sesalin crude product (containing sesalin 62.9% and sesamin 36.2%) 0.5g (containing sesalin 0.85mmol) and 20mL petroleum ether and added it to the In a 50mL three-necked flask (the initial concentration of sesaline is 42.5mmol·L -1 ), stirred and preheated to 100 °C, and then added 15 g of silicotungstic heteropolyacid catalyst activated at 200 °C for 3 h (17.6 g·mmol relative to the initial sesamin -1 ), continue to stir and keep the reaction at 100 °C for 2 hours, and the reaction solution at the time of HPLC determination of the reaction for 2 hours is converted into sesaminol with a yield of 90.2%. After cooling, suction filtration, the catalyzer is washed twice with acetone again, and the washing solution obtained twice is combined with the organic phase obtained by suction filtration and adopts preparative liquid chromatography to collect the sesaminol component at 295 nm, and t...

Embodiment 2

[0023] A method for preparing sesaminol by catalyzing sesalin, specifically: get sesalin pure product (purity is 98%) 80mg (0.216mmol) and 20mL ethylbenzene and join in the 50mL three-necked flask (the sesalin initial concentration is 10.8 mmol·L -1 ), stirred and pre-heated to 90°C, and then added 3 g of silico-molybdenum heteropolyacid activated at 200°C for 3 h (13.89 g·mmol relative to the initial sesamin -1), continue to stir and keep the reaction at 90°C for 1.5h, the reaction solution at 1.5h was measured by HPLC, and the yield of sesaminol was 87.9%. After cooling, suction filtration, wash the catalyst twice with ethyl acetate, combine the washings obtained twice and evaporate the solvent under reduced pressure together with the organic phase obtained by suction filtration to obtain a yellow-brown paste-like solid, which is purified by silica gel column chromatography. N-hexane and ethyl acetate are eluted at 5:1, TLC detects, collects sesaminol components, evaporates...

Embodiment 3

[0025] A method of catalyzing sesalin for the preparation of sesaminol, specifically: get sesalin pure product 66mg (purity is 98%, 0.18mmol) and 10mL benzene join in the 25mL three-necked flask (the sesalin initial concentration is 18mmol L -1 ), stirred and pre-heated to 70 °C, and then added cesium phosphotungstic heteropolyacid (Cs) activated at 200 °C for 2 h 2.5 H 0.5 PW 12 O 40 ) 0.72g (4g mmol relative to initial sesaline -1 ), continue to stir and keep the reaction at 70°C for 4h, the reaction solution at 4h was measured by HPLC, and the yield of sesaminol after conversion was 82.5%. Then handle according to the method of embodiment 2, obtain yellow-brown sesaminol solid 43.5mg, HPLC measures total sesaminol content to be 98.2%, and yield is 63.6%. The pure sesaline and benzene were dehydrated and dried before the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com