Cap-screwing machine chuck

The technology of capping machine and claw head is applied in the field of capping machine claw head, which can solve the problems of insufficient equipment optimization, complicated mechanism design, complicated design, etc., and achieve the effects of excellent overall machine, simplified design and reduced cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

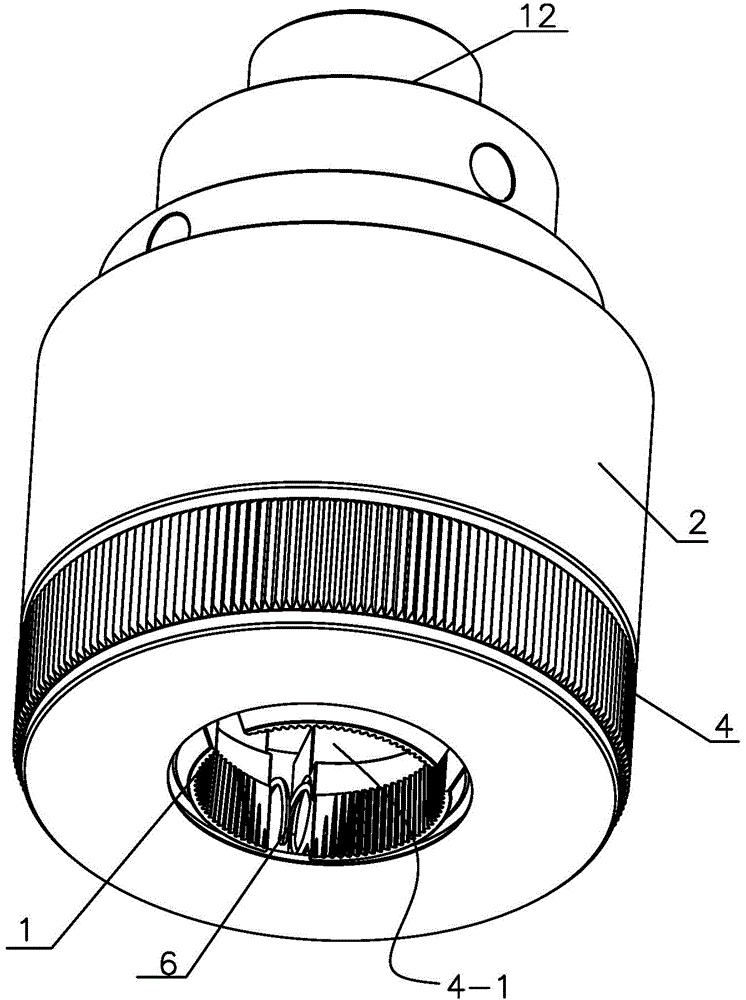

[0032] Such as Figure 4 , the claw seat 2 has an inner cavity, the bottom of the claw seat 2 is equipped with a claw cover seat 4, the center of the claw cover seat 4 has a bottle cap inlet 4-1, and several claws 1 evenly surround the inner cavity of the claw seat 2 and are placed on the claw cover seat 4 on;

[0033] Such as figure 2 image 3 , the pusher 3 includes a piston 5, the outer ring of the piston 5 is in sealing and sliding contact with the inner cavity of the claw seat 2, the bottom surface of the piston 5 is provided with the same number of wedges 5-1 as the number of claws 1, and each claw 1 is provided with a chute 1 -1, the wedge 5-1 on the bottom surface of the piston 5 is correspondingly inserted into the chute 5-1;

[0034] The inclination direction of the wedge 5-1 and the chute 1-1 is upwardly inclined from the outside to the inside, and the surrounding claws 1 are connected with the claws 1 by a compression spring 6 .

[0035]It also has a pin 7 and...

Embodiment 2

[0037] Such as Figure 5 , the claw seat 2 has an inner cavity, the bottom of the claw seat 2 is equipped with a claw cover seat 4, the center of the claw cover seat 4 has a bottle cap inlet 4-1, and several claws 1 evenly surround the inner cavity of the claw seat 2 and are placed on the claw cover seat 4 on;

[0038] Such as figure 2 image 3 , the pusher 3 includes a piston 5, the outer ring of the piston 5 is in sealing and sliding contact with the inner cavity of the claw seat 2, the bottom surface of the piston 5 is provided with the same number of wedges 5-1 as the number of claws 1, and each claw 1 is provided with a chute 1 -1, the wedge 5-1 on the bottom surface of the piston 5 is correspondingly inserted into the chute 5-1;

[0039] The inclination direction of the wedge 5-1 and the chute 1-1 is upwardly inclined from the outside to the inside, and the surrounding claws 1 are connected with the claws 1 by a compression spring 6 .

[0040] There is also a pin sh...

Embodiment 3

[0042] Such as Figure 6 , the claw seat 2 has an inner cavity, the bottom of the claw seat 2 is equipped with a claw cover seat 4, the center of the claw cover seat 4 has a bottle cap inlet 4-1, and several claws 1 evenly surround the inner cavity of the claw seat 2 and are placed on the claw cover seat 4 on;

[0043] Such as figure 2 image 3 , the pusher 3 includes a piston 5, the outer ring of the piston 5 is in sealing and sliding contact with the inner cavity of the claw seat 2, the bottom surface of the piston 5 is provided with the same number of wedges 5-1 as the number of claws 1, and each claw 1 is provided with a chute 1 -1, the wedge 5-1 on the bottom surface of the piston 5 is correspondingly inserted into the chute 5-1;

[0044] The inclination direction of the wedge 5-1 and the chute 1-1 is upwardly inclined from the outside to the inside, and the surrounding claws 1 are connected with the claws 1 by a compression spring 6 .

[0045] It also has pin shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com