Double-surface laminating material bag opening mechanism with hot cutting lifting handle

An eager and hand-holding technology, applied in packaging and other directions, can solve problems such as loss and large deviation of material weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

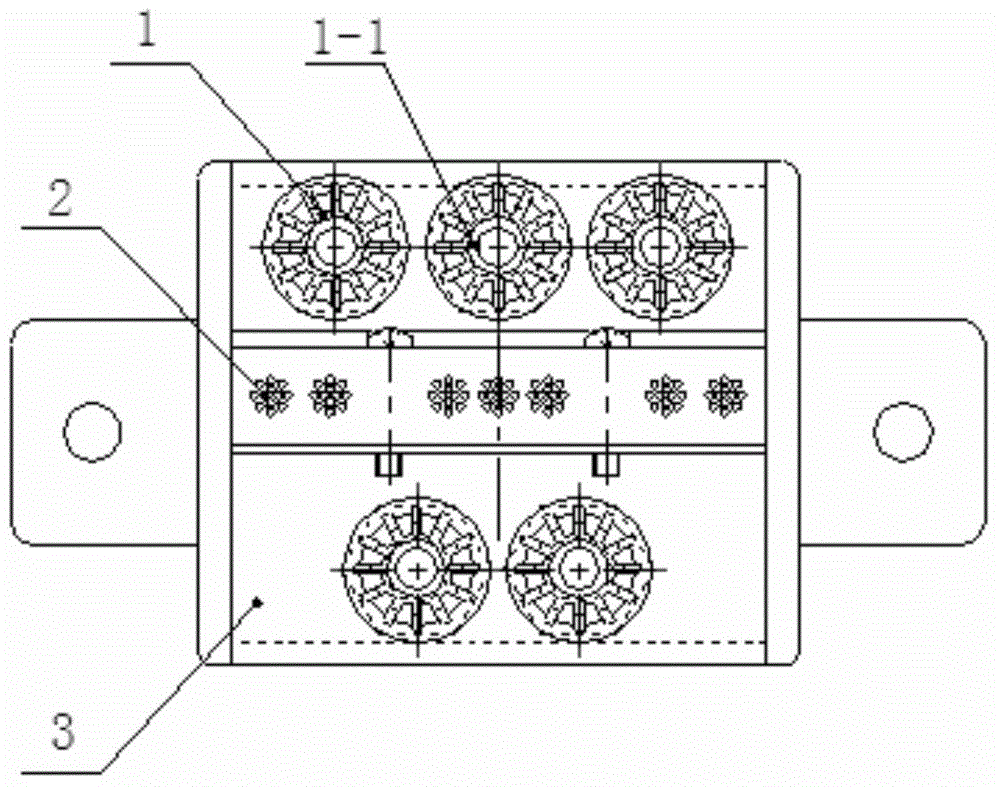

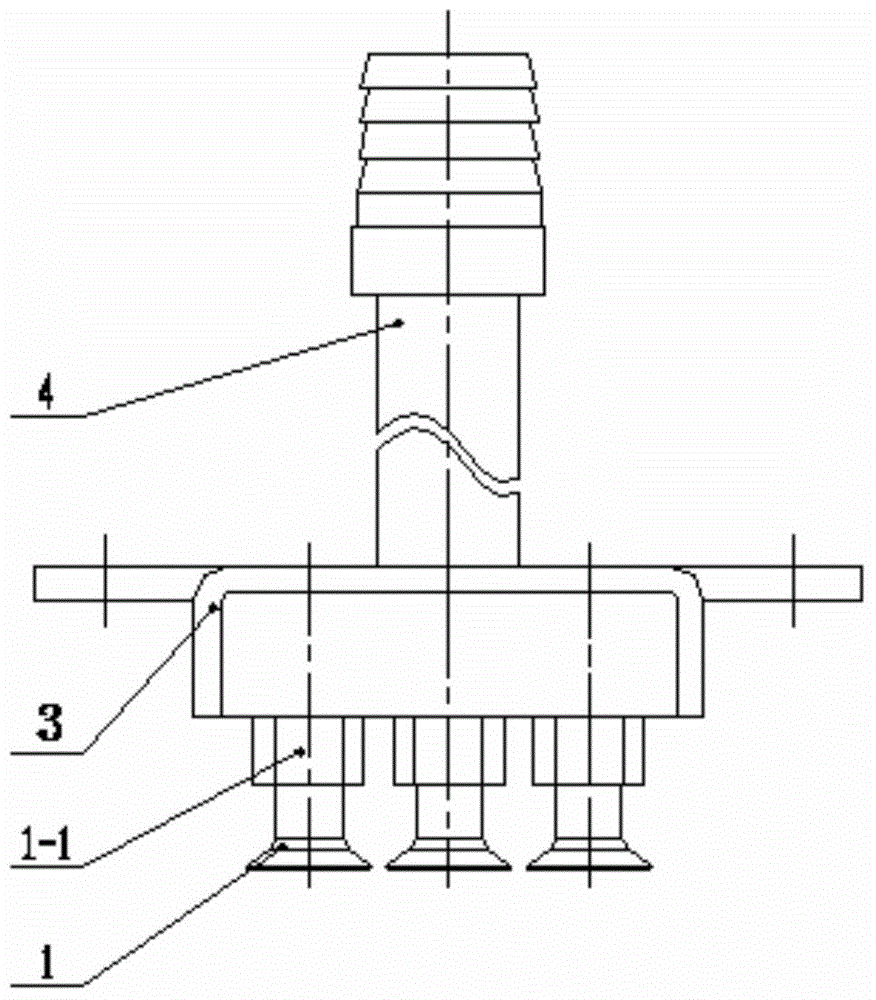

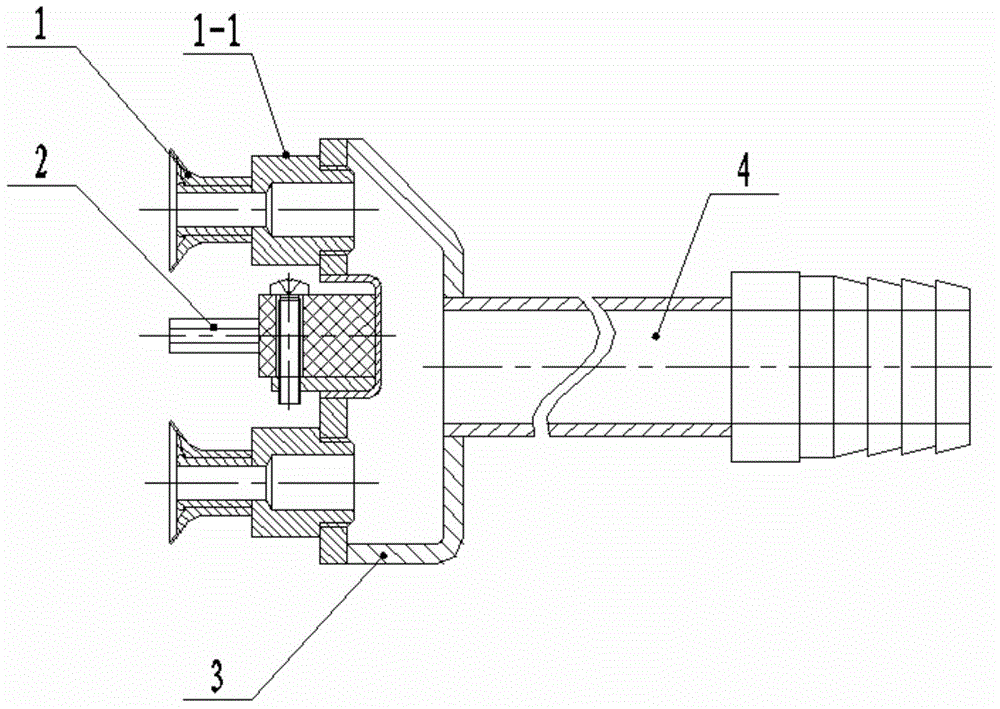

[0014] Referring to the accompanying drawings, a bag opening device for filling material bags with hot-cut buckles of an automatic packaging unit includes vacuum housings 3 opposite to each other on the left and right sides. The rear end of the vacuum housing 3 is connected to a vacuum pipeline 4. The vacuum housing The front end of the body 3 is connected with suction cups 1 arranged in a row, the suction cups 1 are installed on the vacuum housing 3 through the joint 1-1, the center of the suction cup 1 is installed with a support brush 2 arranged in an arrangement, and the suction cups 1 on the left and right sides are clamped together At the 5-button hand part of the woven bag; the left and right support brush clips are placed at the eager button 5-1 of the woven bag.

[0015] The working principle of the present invention:

[0016] Figure 4 Among them, the woven bag 5 and the eager clasp hand 5-1, when the bag opening mechanism opens the bag, the two bag opening mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com